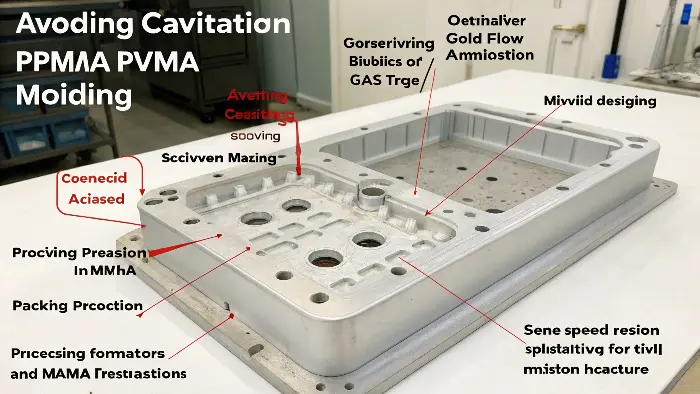

How Does CavityMold Nail High-Precision PMMA Injection Molding Every Time?

Struggling with PMMA parts that don’t meet spec? Precision is tough. CavityMold delivers flawless PMMA components, mastering the art of high-precision molding. CavityMold achieves high-precision