How Do You Select the Right Medical-Grade Plastic Using ISO 10993?

Choosing the right material for a medical device is a high-stakes decision. A wrong move can lead to device failure, patient harm, and regulatory nightmares.

Choosing the right material for a medical device is a high-stakes decision. A wrong move can lead to device failure, patient harm, and regulatory nightmares.

Are you trying to plan a product launch but feeling stuck on the timeline for your injection mold? The uncertainty can be frustrating. A delay

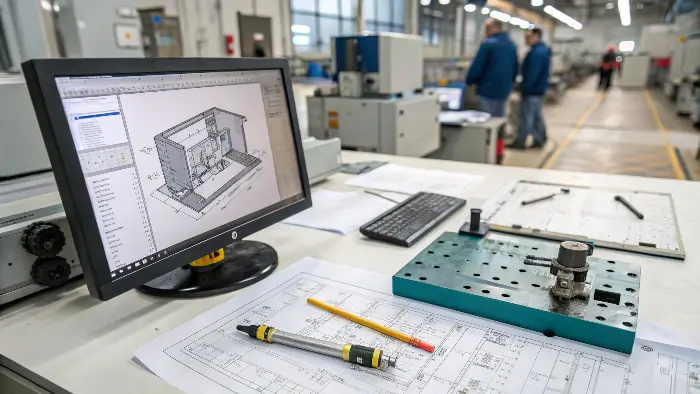

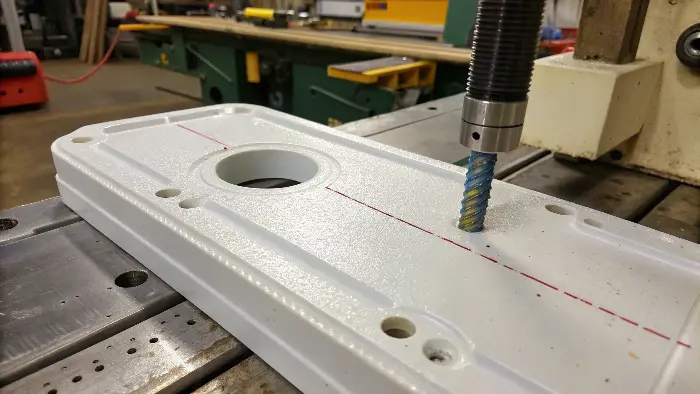

Getting a high-quality plastic part depends entirely on a perfect mold. A flawed mold can cause production delays, wasted materials, and poor product quality. Understanding

Are you aiming for a career as a top-tier mold designer but feel lost about where to start? The path can seem confusing, requiring a

Trying to understand injection molding from text alone can be confusing and leave you with an incomplete picture. Without clear visuals, you might misinterpret key

Struggling with inconsistent part quality? Defects like warping and poor surface finish can ruin a production run and drive up costs. These issues often trace

As a project manager, you’re constantly balancing cost, quality, and speed. But now, there’s another critical factor: sustainability. Seeing piles of plastic runners and rejected

Designing plastic parts for injection molding can feel like navigating a minefield. A small oversight in your design can lead to expensive mold modifications, production

You’ve just opened a box of freshly molded parts, but your heart sinks. The surfaces are covered in wavy patterns and faint lines, making them

Choosing the right manufacturing process can feel like a high-stakes gamble. You need quality parts, but you also have a budget to protect. Opt for

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”