INJECTION MOLDING OF PEEK

Polymers have replaced metals in many applications in the medical and other industries. This has led to improved treatment and management of several medical conditions.

Polymers have replaced metals in many applications in the medical and other industries. This has led to improved treatment and management of several medical conditions.

If you are always curious about how things get made, at some point you would have taken a look at a plastic product. You would

There are some disadvantages of injection moulding. Not Fit For Low Volume This method is suitable for large production volumes. It’s an ideal process for

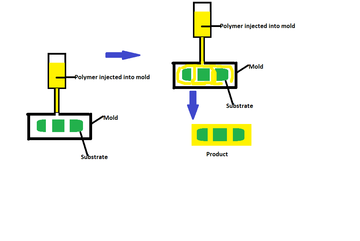

Vertical injection molding works on the same fundamental principles as conventional injection molding. The simple variation in orientation makes a huge difference in the manufacturing

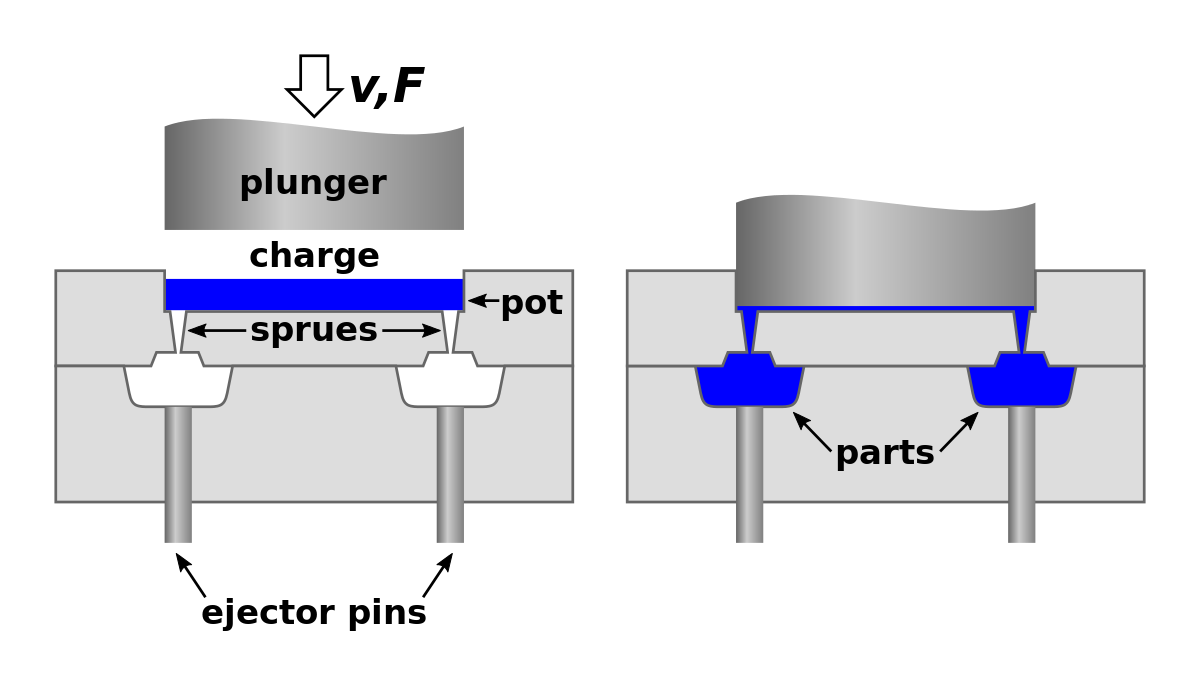

Injection moulding is a prime method used for producing large numbers of articles. This method gets the advantage over other manufacturing methods. It has a

When industries need intricate parts, they turn to custom injection molding services. Custom injection molding works best where you need large volumes of parts. Before

Injection molding is pretty much standard for manufacturing consumer products. Especially those with complex designs and/or required in large quantities. The method is well established

Polymers are a very diverse group of compounds. They are also ubiquitous. They exist in nature and are also synthesized by man. Polymers exist in

Plastics have become one of the most important materials of the modern age. They cut across several industries. Shopping bags, coffee cups, food bowls, and

Believe it or not, plastic injection molding is very old. The first injection mold machine was made by two brothers in the 19th century. With

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com