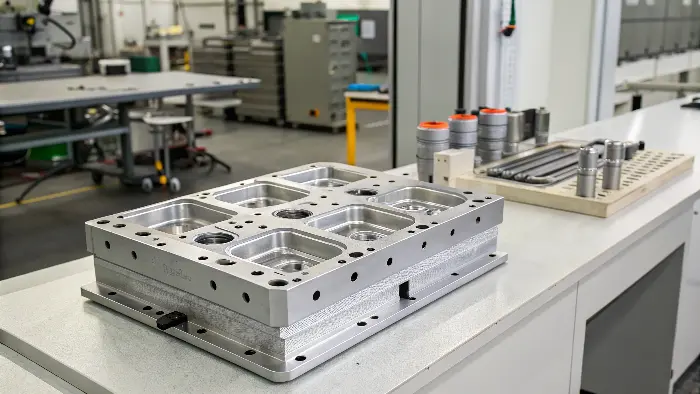

CNC Machined Aluminum vs. Injection Molded PEEK: A Showdown for High-Performance Automotive Parts?

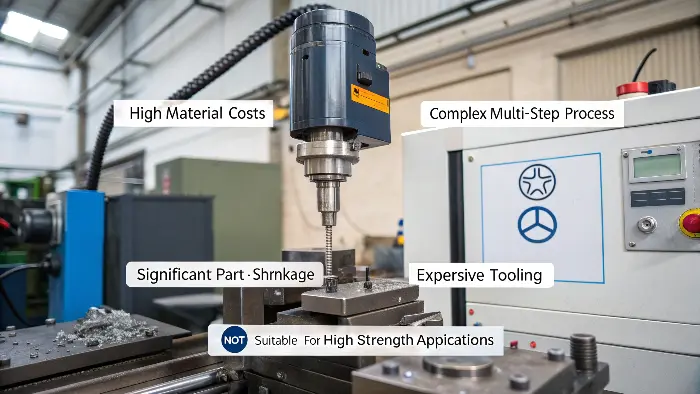

Are you struggling to choose the best manufacturing process for your high-performance auto parts? The wrong decision can lead to failed components, project delays, and