How Can You Guarantee Quality in Precision Injection Molded Parts?

Are you struggling with inconsistent quality in your precision molded parts? A single bad batch can cause production delays, increase costs, and damage your brand’s

Are you struggling with inconsistent quality in your precision molded parts? A single bad batch can cause production delays, increase costs, and damage your brand’s

Are you struggling to decide between standard and precision injection molding for your next project? Choosing the wrong process can lead to parts that don’t

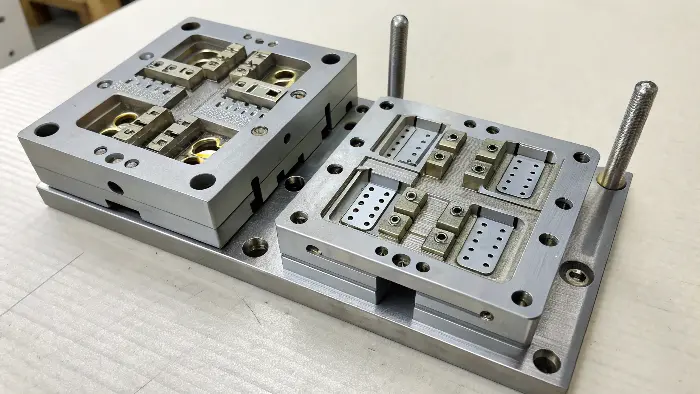

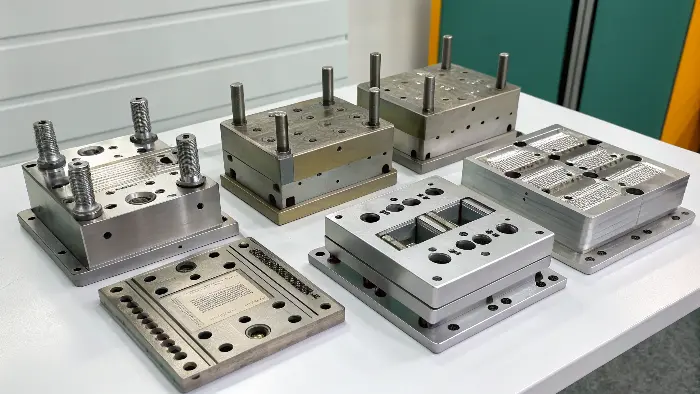

Taking a product to high-volume production often means using a high-cavitation mold. But what happens when your part has undercuts requiring sliders? The complexity multiplies.

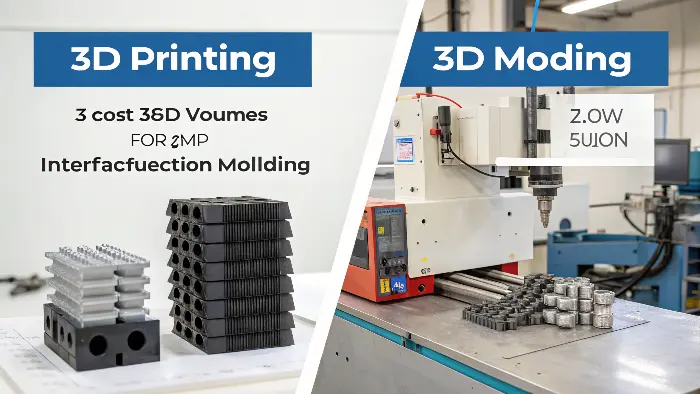

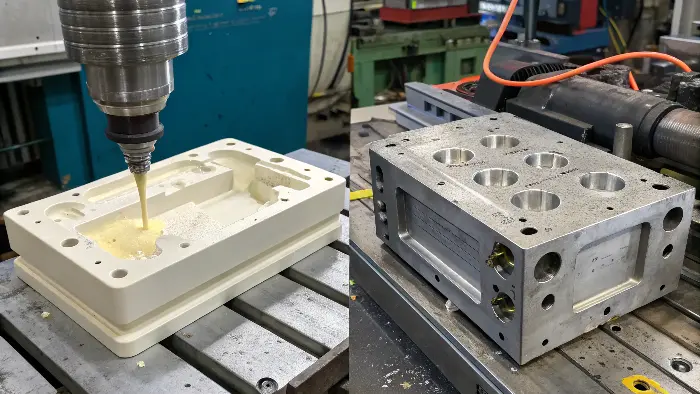

You’re looking at thin wall injection molding, but the initial tooling costs seem huge. It’s a big investment, and you’re worried about the ROI. Making

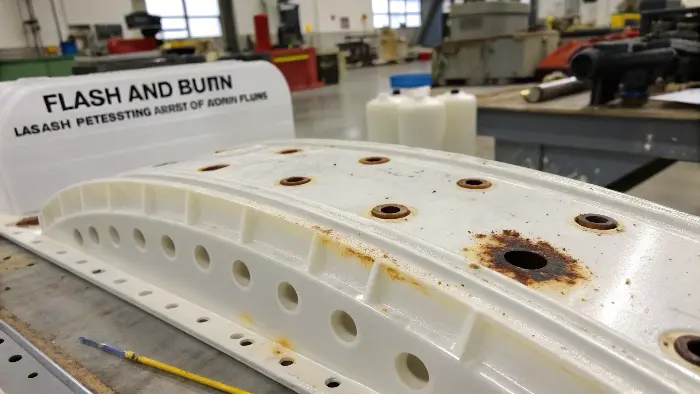

Are you pulling your hair out over a pile of rejected thin-wall parts? Short shots, warped pieces, and ugly flash can turn a profitable project

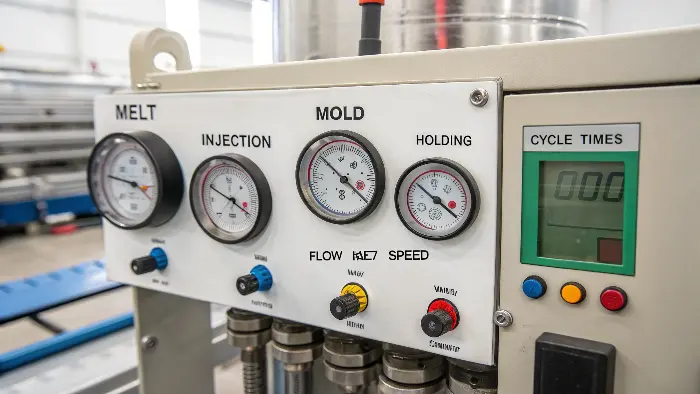

Struggling with inconsistent shot sizes or annoying defects in your molded parts? It’s a common headache in injection molding, leading to wasted material and time.

Ever find yourself wondering if injection molding is always the king of manufacturing processes? It’s fantastic for high-volume, complex parts, no doubt. But sometimes, the

Ever felt a bit lost trying to figure out what exactly a PET preform injection mold is? It sounds super technical, and maybe you’re wondering

Struggling to understand how those perfect plastic parts are made in huge numbers? Injection molding might seem like a complex industrial secret. But knowing its

Tangled cables are a nightmare, right? It’s not just messy; it can be a real headache for safety and efficiency. You rely on cable ties

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”