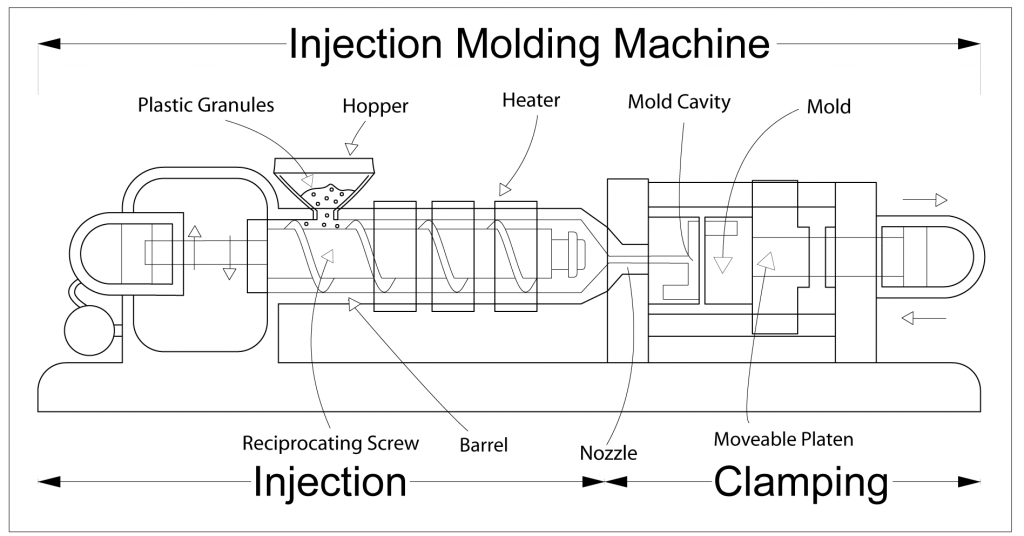

Injection moulding is a prime method used for producing large numbers of articles. This method gets the advantage over other manufacturing methods. It has a tough geometry, product consistency, and low labour cost for making similar items.

We inject molten plastics at high volume into a mould to create shapes and articles. You can get many materials such as a bottle cap, pocket comb, car panels, and mechanical parts.

The injection moulding process has become a utilised strategy. The reason is its merit and extra benefits that it offers.

It’s performed with other materials like elastomers, metals, glasses, and polymer. We can produce a complicated part in an automatic and fast operation.

Some factors that affect the injection moulding and other plastic processes are:

- Heat

- Temperature

- Thermal Stability

- Crystallinity

- Thermal Conductivity

- Viscosity

- Moisture

What makes this method so reliable than other moulding processes?

The design flexibility and fast production make it unique in the modern world.

What Are The Advantages of Plastic Injection Moulding?

The following are the major aspects of injection moulding. You can create plastic components and parts.

1:Complex Geometry/ Large Material Selection

We can produce complex and intricate designs due to high pressure. High pressure makes it easy for us to imprint detail onto the part. With a scientific approach and tools, it gives us unlimited flexibility for design. We can create complex design and features.

With metal injection moulding machines, we can produce surgical instruments. We can get these products at affordable prices. We can also get cost-effective products with the help of MIM. A large selection of material gives us more choices to create the design. We can change TPE onto PP parts.

2: Fast & Efficient / High Consistency

Its high output production and repeatable designing make it an ideal method. You can generate various articles. You may get incredible parts per hour, and its speed depends on the intricacy and size of the mold. You make a repeatable and consistent design in a single mould. This high output production rate produces cost-effective and consistent results.

You can produce bulk products in minimal time input. Less supervision makes this process efficient and reliable. Mechanical fabrication, computerised machines, and 3D design units play a crucial role. They’re helpful in generating outstanding quality products.

3: Provide Many Finishes & Colour Control

Are you looking for a smooth and matte finish? Injection moulding gives many finishes and unique texture. The ability to manufacture various designs is a major advantage of injection moulding. It’s performed with the help of co-injection molding.

You don’t need any post-production work or secondary operation to get a good finish look. Injection moulding gives articles a final and smooth surface. You can produce plastic products in any colour.

4: Strength & Durability

Lightweight and durable plastic molded products are now in demand. You can see using these plastic products in most rugged environments. Plastic created with this process is of high quality, affordable, and sturdy. It can hold out against any environment.

Plastic injection moulding makes it possible to use filler in the injection mould. When these fillers are mould, they reduce the density of the plastic. They enhance the strength and durability of the completed articles and parts. Products made by injection moulding are durable, consistent, and sturdy.

5: Low Cost & Time Saving

You can get significant competitive advantages and an optimised supply chain. Plastic injection moulding is the most effective method. It’s an automated process performed by robots and machines. Automotive injection molding also helps plastic parts consolidation, a type of industry. It’s useful in minimising the labour cost and the need for expensive tools.

Computer-aided design and computer-aided manufacturing decrease the cost and time. It creates an accurate and precise design in one step. You may feel moulding costly at the initial stage. Its value decreases in long-term production. We can create plastic parts with one mould. Plastic design with Injection molding is twenty-five times less costly than other methods.

6: Reduction of Waste & Scrap

Destruction of a healthy environment and ecology is a primary concern of our age. The plastic industry is one of the non-biodegradable solid generated industries. You may find it eco friendly as it only uses the required amount of plastic. It doesn’t leave out massive waste and scrap behind. The extra scrape and trash can recycle with state of the art machinery. Otherwise, you can underground it for further usage.

How Can You Get The Application Of Plastic Injection Molding?

You want to get benefit from all the injection molding process assets. You should make sure to have some clarification about the plastic molded company.

Do you want to utilise all the beneficial features of the injection molding process? Then get the answer to all questions before starting your project.

- Do they have injection moulding equipment, technology, and material for your project?

- Do they have experienced engineers? Do they have knowledge of how to get high output production?

- Do they have the ability to solve any critical issue? Can they overcome it in the mould creations?

- Does your supplier have in-house engineering experts in this field?

- Does the moulder know? How to maximise the result and efficiency?

- Can they understand the complexities and nature of your products?

- Can they have testing procedures? Do they have the scientific moulding and over moulding skills?

- It’s not easy for every person to understand how injection molding works? Mold manufacturers need special training for providing its services.

- Do they know how to use the core and cavity? Can they make the components’ internal and external shapes?

Suppose you get good feedback and response to the above questions. You’re choosing one of the best injection molding manufacturers for your projects. It can meet all your desired requirements. You can get all the advantages of injection moulding.

What Are The Injection Moulding Defects? How Can You Fix These Defects?

Production of intricate and novel parts requires a high level of expertise. You have to give attention to prevent mistakes and damage. While we discuss the pros and cons of the injection moulding process. You may have to face some disadvantages during the molding procedure. These faults can affect the quality, and function of the products. You must have some knowledge of general molding defects. You should know that how you can resolve these defects?

The most common factors for these failures are:

- Lack of skilled personnel having good experience in the relative field

- Ejection of right tools

Some common quality defects are:

- Flow Lines

- Vacuum Voids

- Weld Lines

- Wrapping

- Jetting

- Burn Marks

- Flash

- Short Shot

- Surface Delimitation

- Sink Marks

Finding expert injection molding engineers is essential in the manufacturing process. You must be aware of all techniques and principles of injection molding. It’ll be helpful for getting good quality output production rate. The use of Solidworks would be useful for the identification of defects. By knowing the causes and solutions of these shortcomings, you can get rid of these flaws.

A

To Conclude:

Injection moulding is an eco-friendly process. It has no abs type that you found in 3D printing; it’s a tremendous and real procedure. In this method, the waste material generated ratio is very less as compared to other methods. You don’t need post-production work in the injection moulding method. Articles have good finishes after the injection mold’s ejection. This method is one of the most acceptable methods. You can produce complex plastic articles in a wide range. Cost efficiency and low cost make it rare and exceptional for the plastic industry.