Think Injection Molding is Just For Your Phone Case and Gadgets?

Tired of seeing molding only in simple items? It’s time to see its vast, unseen industrial power. This changes everything, you know? Injection molding is

Tired of seeing molding only in simple items? It’s time to see its vast, unseen industrial power. This changes everything, you know? Injection molding is

Choosing the right polyamide feels like navigating a maze. Pick the wrong one, and you risk part failure, budget overruns, and project delays. This guide

Choosing between Mexico and Asia for your injection molding is a huge decision. The wrong choice can lead to blown budgets, delayed timelines, and quality

Are you tired of injection molding projects going off the rails? Focusing only on the lowest price or the closest supplier often leads to poor

Choosing the wrong injection molding partner can derail your entire project with costly delays, poor quality, and budget overruns. The pressure mounts as you face

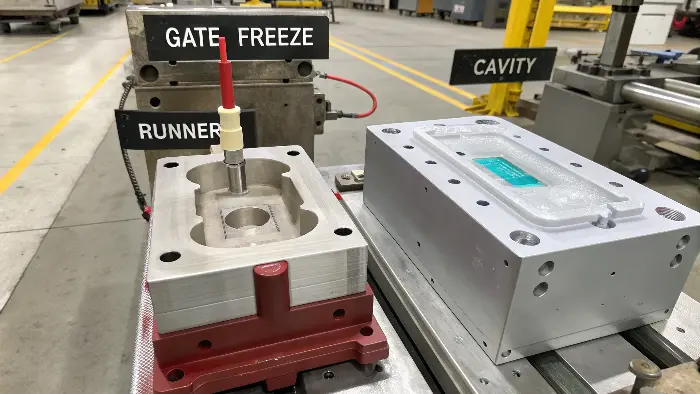

Seeing those ugly jetting marks on your parts? It’s a common headache, leading to weak, unsightly products. But what if the gate design itself holds

Are you feeling stuck trying to figure out the correct interior wall thickness for your project? Getting this detail wrong can lead to big problems

Struggling with intricate parts or tight tolerances? High-pressure injection molding might be your answer. Let’s explore how CavityMOLD masters these complex manufacturing challenges. Yes, CavityMOLD’s

Seeing strange snake-like patterns on your parts? This defect, jetting, weakens products and wastes money. So, how do you stop it? Jetting is a molding

Facing complex parts or tight tolerances? High-pressure molding offers precision, but how does CavityMold elevate this? Discover our advanced capabilities. CavityMold leverages advanced high-pressure injection

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”