What is the setting analysis of injection mold temperature?

Struggling with inconsistent part quality? Defects like warping and poor surface finish can ruin a production run and drive up costs. These issues often trace

Struggling with inconsistent part quality? Defects like warping and poor surface finish can ruin a production run and drive up costs. These issues often trace

You’ve just opened a box of freshly molded parts, but your heart sinks. The surfaces are covered in wavy patterns and faint lines, making them

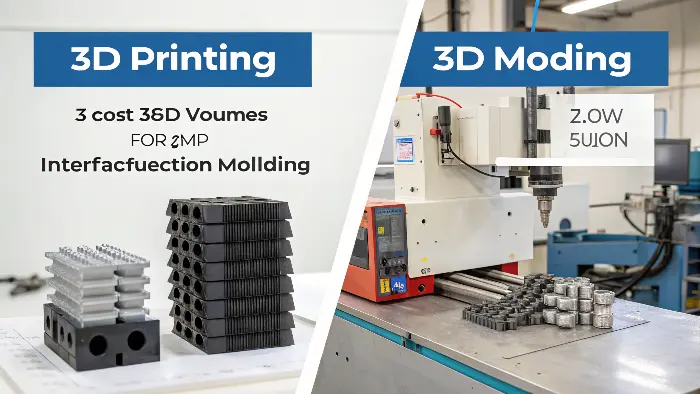

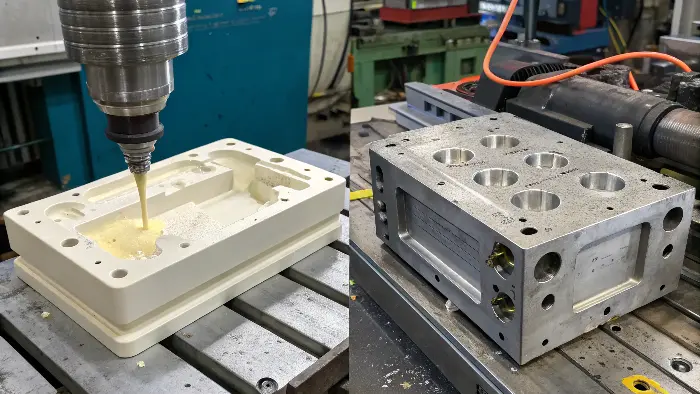

Choosing the right manufacturing process can feel like a high-stakes gamble. You need quality parts, but you also have a budget to protect. Opt for

Are you struggling with inconsistent quality in your precision molded parts? A single bad batch can cause production delays, increase costs, and damage your brand’s

Are you struggling to decide between standard and precision injection molding for your next project? Choosing the wrong process can lead to parts that don’t

You’re looking at thin wall injection molding, but the initial tooling costs seem huge. It’s a big investment, and you’re worried about the ROI. Making

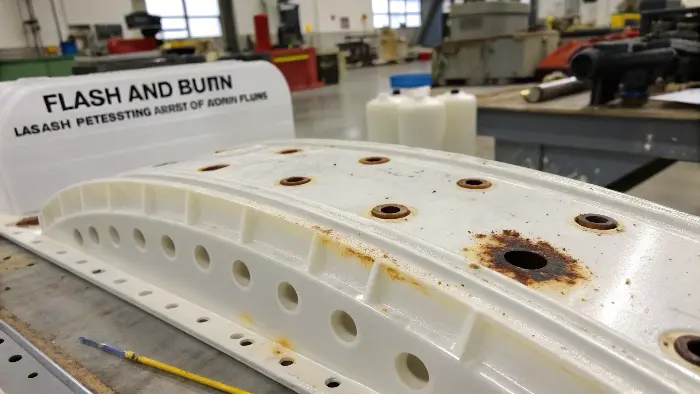

Are you pulling your hair out over a pile of rejected thin-wall parts? Short shots, warped pieces, and ugly flash can turn a profitable project

Struggling with inconsistent shot sizes or annoying defects in your molded parts? It’s a common headache in injection molding, leading to wasted material and time.

Ever find yourself wondering if injection molding is always the king of manufacturing processes? It’s fantastic for high-volume, complex parts, no doubt. But sometimes, the

Ever felt a bit lost trying to figure out what exactly a PET preform injection mold is? It sounds super technical, and maybe you’re wondering

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”