What are the seven basic components of injection molding, and why should you care?

Ever felt a bit lost when engineers start talking about molds? It’s a complex world, and not knowing the basics can make you feel out

Ever felt a bit lost when engineers start talking about molds? It’s a complex world, and not knowing the basics can make you feel out

Feeling overwhelmed trying to get your plastic parts made in China? It’s a common headache – you hear about the cost savings, but then the

Struggling with inconsistent part quality or long cycle times? Your mold temperature might be the culprit, causing a heap of production headaches. Getting this setting

Struggling with slow, error-prone manual checks for your intricate molds? It’s frustrating when production halts because inspections take forever, right? Well, modern 3D inspection techniques

Struggling with inconsistent injection molding quality that leads to wasted materials and unhappy customers? It’s a real headache, right? I’m here to share how we

Struggling with costly mold rework and production delays? These issues often stem from unforeseen problems in your product design that only appear during manufacturing. Imagine

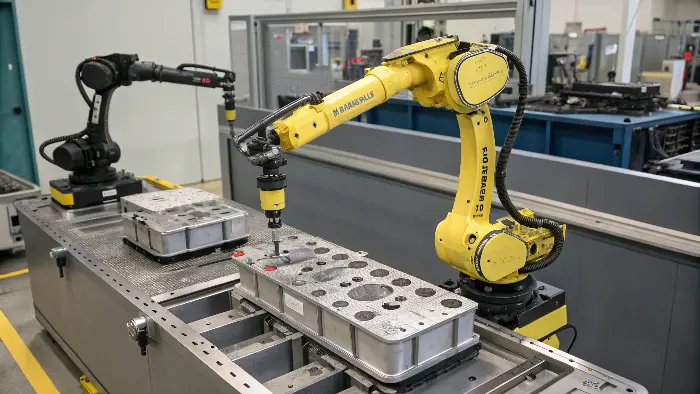

Tired of manual insert loading slowing you down? Inconsistent placements and high labor costs eating into profits? You know automation could be the answer, but

Struggling with your insert molding projects? It’s a common headache when things go wrong, leading to delays and wasted materials. You want smooth production, but

Struggling to get that perfect, consistent color for your plastic products? It can be frustrating when the final product doesn’t match your design intent. Masterbatches

Struggling with inconsistent colors or weak plastic parts? Advanced masterbatches offer solutions, transforming your injection molding projects from basic to brilliant. It’s a real game-changer.

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”