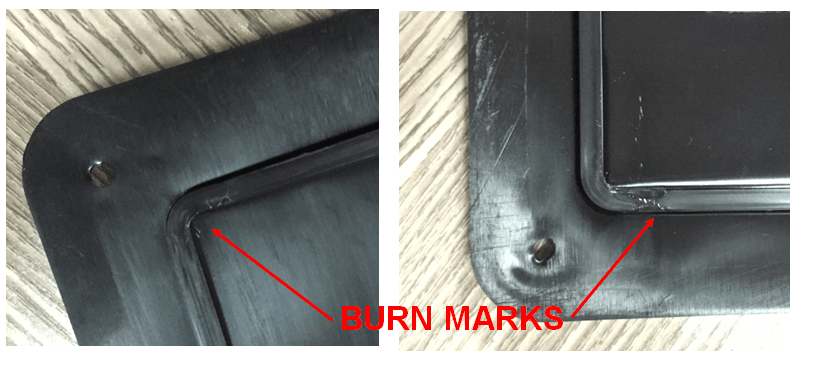

WHAT CAUSES BURN MARKS AND HOW TO FIX THEM IN PLASTIC INJECTION MOULDING?

Injection molding can’t be exempt without defects and errors. There are many rooms for expensive defects. Some defects are unrepairable, but some can fix. Many

Injection molding can’t be exempt without defects and errors. There are many rooms for expensive defects. Some defects are unrepairable, but some can fix. Many

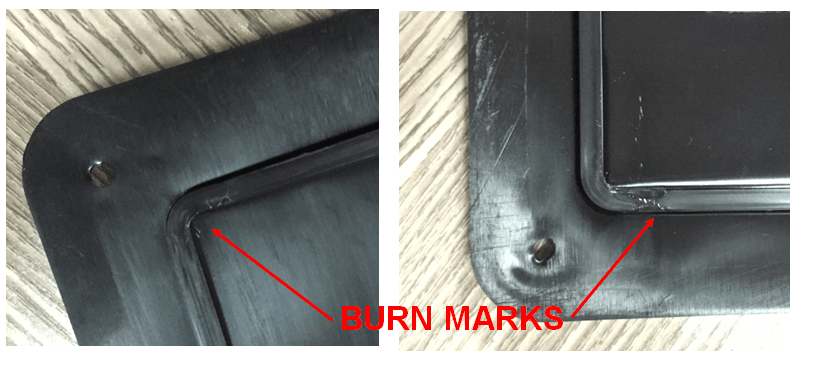

Warpage is one of the possible defects that can occur in injection molding. It results in the disfigurement of the product. A warped part most

Polymethyl methacrylate (PMMA) or acrylic is a well-established thermoplastic. It has come to be well known in the plastic industry. It is a good choice

Imagine living in a world where we do not fear quality. What if we all had a fearless reaction to the phrase quality. Imagine what

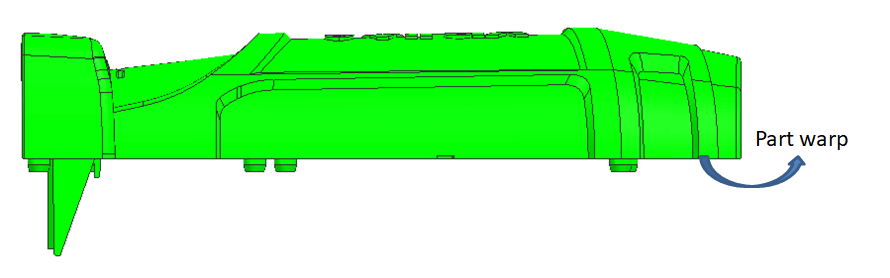

Injection molding has the potential to achieve efficient and fast plastic part manufacturing. Identical parts get made in repeated cycles without defects. Thus leading to

Around 32kg out of every 100kg of plastics processed globally uses injection molding. This makes injection molding an important manufacturing process. The success of injection

When the injection molding process runs well, it can all seem so straightforward. In reality, to ensure that every product comes out of the process

The conventional injection molding process manufactures products that meet diverse industry needs. But some products need some modifications to the conventional injection molding process. This

Thin wall molding is gaining popularity due to its lower material cost and high production output. A thin wall refers to an electronic part that

Nylon66 or PA66 as it is also known as polyamide. Polyamides are a class of polymers which are thermoplastics. characterized by the amide group in

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”