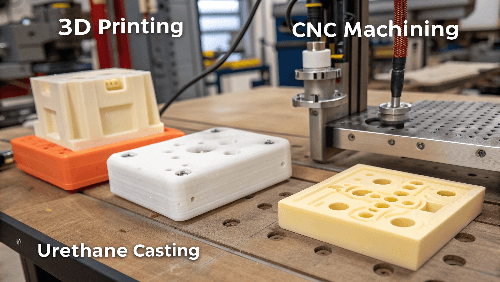

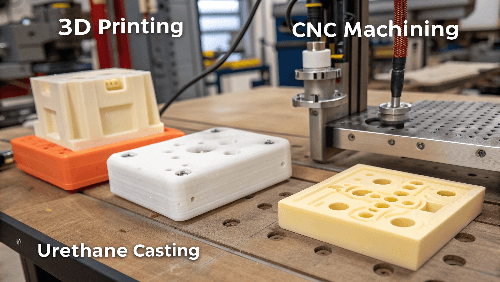

How Are Modern Technologies Tackling Injection Molding’s Downsides?

Injection molding is powerful, but are its drawbacks holding you back? High costs, long waits, and design limits can frustrate even experienced designers and stall

Injection molding is powerful, but are its drawbacks holding you back? High costs, long waits, and design limits can frustrate even experienced designers and stall

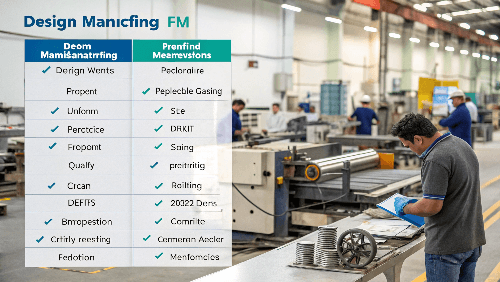

Designs look great on screen but cause molding headaches? Frustrating defects, high costs, and delays plague production, eating into your budget and timeline. DFM (Design

Struggling with flawed plastic parts? Trapped air causes burns and short shots, wasting time and money. Proper mold venting is the key fix you might

If you’re searching for the best mold manufacturer in Shenzhen, you’re not alone. Every week, hundreds of businesses—especially from the U.S. and Europe—type that exact

In a world where innovation cycles are shrinking and speed-to-market often dictates success, choosing the right manufacturing partner can make or break a product launch.

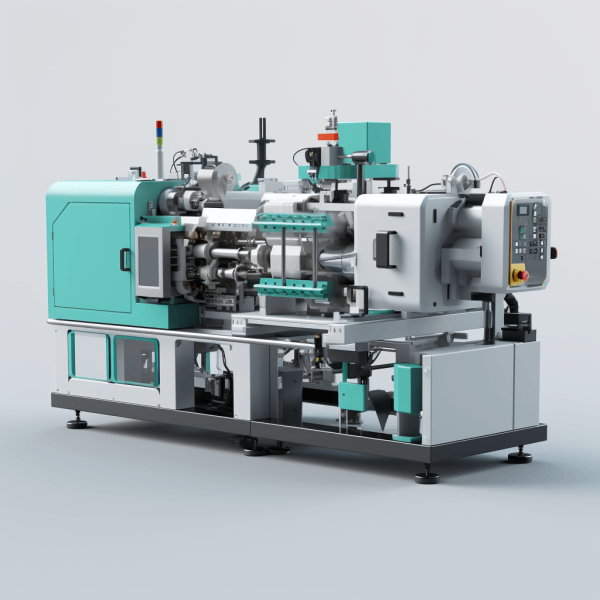

In today’s hyper-competitive manufacturing landscape, Original Equipment Manufacturers (OEMs) are under more pressure than ever to reduce lead times, cut costs, and increase the speed

The injection molding process, paramount in the manufacturing of a plethora of plastic products, hinges on efficiency and precision. A crucial determinant of the overall efficiency in injection molding is the cycle time. A reduction in cycle time can yield increased productivity and lower costs, making it a focal point for manufacturers aiming to optimize their operations.

Ever found yourself gazing at a plastic container and wondering, “How on earth is this made?” Well, you’re about to embark on a fascinating journey! Sit tight!

Have you ever looked at a plastic bottle cap and wondered how such a small piece could be so intricately designed? Why Plastic Bottle Caps? Plastic bottle caps play a pivotal role in sealing beverages and ensuring they stay fresh. Their design ensures they are airtight and leak-proof. Let’s dive into their manufacturing journey!

Ever strolled through a store, taken a closer look at products, and wondered where they came from? Would it surprise you to know that a good number of them are manufactured through injection molding in China? Let’s dive in!

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”