Designs look great on screen but cause molding headaches? Frustrating defects, high costs, and delays plague production, eating into your budget and timeline.

DFM (Design for Manufacturability)1for injection molding2 means designing parts specifically for easy, cost-effective, and high-quality manufacturing. It involves applying specific guidelines early in the design phase to prevent problems.

I’ve seen countless projects face challenges because manufacturability wasn’t considered early enough. For designers like Jacky, who need to balance aesthetics, function, and large-scale production, understanding DFM isn’t just helpful; it’s essential for success. Thinking about how the part will actually be made right from the start saves enormous amounts of time and money. Let’s break down what DFM really means for injection molding.

What is DFM in injection molding?

Confused about what DFM actually involves for plastic parts? Ignoring it leads to complex molds, slow cycles, and avoidable production issues down the line, frustrating everyone involved.

DFM in injection molding is the practice of proactively designing plastic parts to simplify manufacturing, reduce tooling costs, minimize defects, and ensure smooth, efficient production runs through specific design rules.

!

At its heart, DFM is about thinking like a mold maker and a molding technician while you are still designing the part. It forces you to consider the physical process of injecting molten plastic into a steel cavity, letting it cool, and then getting the part out cleanly.

Core Principle: Designing for the Process

Injection molding has specific capabilities and limitations. DFM acknowledges these. Instead of creating a shape and just hoping it can be molded, you design the shape so that it molds well. This involves understanding melt flow, cooling patterns, material shrinkage, and how the part will release from the tool.

Beyond Just Geometry

While geometry is key (like wall thickness and draft angles), DFM also touches on material selection and tolerances. Choosing a material that flows easily and meets performance needs is crucial. Setting realistic tolerances that are achievable with standard molding practices prevents unnecessary costs and quality struggles.

Collaboration is Key

Effective DFM isn’t done in isolation. It requires communication between the part designer (like Jacky), the toolmaker, and the injection molder. Early feedback on a design can highlight potential manufacturing issues before significant time and money are invested in tooling. I always encourage my clients to involve their manufacturing partners early.

What are DFM guidelines for injection molding?

Unsure which design rules really matter for molding? Overlooking key guidelines causes common defects like sink marks, warping, or parts getting stuck in the mold, leading to scrap and delays.

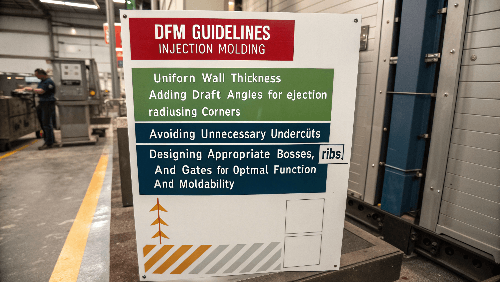

Key DFM guidelines include maintaining uniform wall thickness3, adding draft angles for ejection4, radiusing corners, avoiding unnecessary undercuts, and designing appropriate bosses, ribs, and gates for optimal function and moldability.

Think of these guidelines as the fundamental rules for creating mold-friendly parts. Following them makes the mold simpler to build, the process easier to control, and the final parts much more consistent. I remember a project early in my career where we overlooked draft angles on some deep ribs – getting those parts out of the mold without damage was a nightmare until we modified the tool.

Foundational Guidelines Explained

| Here’s a quick look at why these rules are so important: | Guideline | Purpose | Common Issue if Ignored |

|---|---|---|---|

| Uniform Wall Thickness | Prevents sinks/voids, reduces warping, aids flow | Sink marks, warping, short shots | |

| Draft Angles | Allows easy part ejection from the mold | Scratches, drag marks, stuck parts | |

| Radiused Corners | Reduces stress concentration, improves melt flow | Cracking, breakage, flow issues | |

| Avoid Undercuts | Simplifies mold construction, lowers tool cost | Complex mold (side actions), higher cost | |

| Proper Rib Design | Adds strength without thick walls | Sink marks opposite ribs, warping | |

| Boss Design | Provides mounting points, aligns components | Sink, voids, weak bosses, cracking | |

| Gate Location/Type | Controls plastic flow, affects cosmetics | Weld lines, jetting, cosmetic flaws |

Applying these principles requires careful thought during CAD design. Software tools can help analyze things like wall thickness and draft, but understanding the why behind each rule is crucial for effective DFM.

How can DFM improve product quality?

Struggling with inconsistent part quality or unexpected failures? Poor design choices that ignore manufacturing realities often translate directly into defects that plague production and frustrate end-users.

DFM improves quality by inherently designing out potential defects. Uniform walls prevent sinks5, draft ensures clean ejection, radii reduce stress, and proper gating ensures complete filling6, leading to consistent, reliable parts.

Quality isn’t just about inspection after molding; it starts with the design. When you design a part with manufacturability in mind, you are proactively eliminating the root causes of many common injection molding defects. It shifts the focus from fixing problems to preventing them.

Reducing Common Defects

Many molding defects are direct consequences of ignoring DFM:

- Sink Marks & Voids: Caused by non-uniform wall thickness or thick sections that don’t cool evenly. DFM emphasizes uniform walls and coring out thick areas.

- Warping: Results from uneven cooling and internal stresses, often due to inconsistent wall thickness or poor gate/cooling design. DFM promotes uniformity.

- Flash: Plastic escaping the mold cavity, often due to complex parting lines or insufficient clamp force, which can be exacerbated by poor design choices. Simpler designs = simpler parting lines.

- Short Shots: Incomplete filling of the mold cavity, often caused by walls being too thin, long flow paths, or improper gating – all addressed by DFM.

- Drag Marks/Scratches: Caused by insufficient draft angles during ejection.

Enhancing Structural Integrity & Consistency

By reducing internal stresses (radiused corners) and ensuring complete, even filling and cooling, DFM leads to parts that are inherently stronger and more dimensionally stable. This consistency is vital for assembly and reliable performance in the final product, addressing concerns Jacky might have about meeting functional requirements reliably.

What is optimization of injection molding process?

Think DFM is just about the part design itself? Optimizing the molding process is a separate but related step, and inefficiencies here can cause problems even with a DFM-friendly part design.

Process optimization involves fine-tuning molding parameters like melt/mold temperature, injection pressure/speed, holding pressure/time, and cooling time to achieve the fastest cycle time, lowest defect rate, and consistent part quality for a given design.

While DFM focuses on making the part easy to mold, process optimization focuses on finding the best machine settings to mold that specific part efficiently and consistently. It’s about dialing in the recipe for success once you have a good design and a well-built mold.DFM vs. Process Optimization

Think of it this way: DFM creates a part that has a wide "process window" – a broad range of machine settings that will produce good parts. Process optimization is then finding the most efficient point within that window. A part not designed with DFM principles might have a very narrow process window, making it difficult and expensive to mold consistently, or it might be impossible to find settings that avoid defects altogether.

Key Process Parameters

Technicians adjust variables like:

- Temperatures (Melt & Mold): Affect material viscosity and cooling rate.

- Pressures (Injection & Holding): Ensure complete filling and compensate for shrinkage.

- Speeds (Injection): Influence flow patterns and shear heating.

- Times (Holding & Cooling): Critical for part solidification and dimensional stability.

The Role of Simulation & Scientific Molding

Tools like Moldflow simulation can predict how plastic will flow and cool, helping optimize gate locations and process parameters before cutting steel. Scientific Molding techniques involve systematically testing parameter limits to establish the optimal process window based on data, rather than just trial and error.

How can I improve my injection moulding process?

Facing high scrap rates or slow cycle times despite a good design? The molding operation itself might be the bottleneck, costing time and money unnecessarily due to suboptimal practices.

Improve the process through careful parameter tuning (scientific molding), regular mold maintenance, proper material handling (especially drying), using efficient machinery, and continuous monitoring with robust quality control feedback loops.

Improving the molding process goes beyond just tweaking machine settings; it involves looking at the entire system. A well-designed part (thanks to DFM) makes this much easier, but consistent results demand attention to detail in operations.Scientific Molding Approach

Instead of relying on intuition or old setups, use data. Systematically vary one parameter at a time (like injection speed, holding pressure, melt temperature) while keeping others constant. Measure key part characteristics (weight, critical dimensions) to understand the effect of each parameter and establish a robust process window. This data-driven approach leads to more repeatable results.

Importance of Mold Maintenance

A clean, well-maintained mold is critical. Blocked vents cause gas traps and burn marks. Worn parting lines lead to flash. Damaged ejector pins can mar the part. Regular cleaning, inspection, and preventative maintenance are essential for consistent quality and preventing downtime.

Material Preparation is Crucial

Many plastics, especially engineering resins, are hygroscopic (absorb moisture). Molding damp material causes splay, bubbles, and reduced mechanical properties. Always dry materials according to the manufacturer’s specifications using properly functioning drying equipment. Verify moisture content before molding.

Equipment Matters & Monitoring

Modern, well-maintained machines offer better control and energy efficiency. Ensure auxiliary equipment (chillers, dryers, robots) is also functioning correctly. Implement real-time process monitoring and regular quality checks (first-off, in-process, last-off) to catch deviations quickly before large numbers of bad parts are produced.

How can I make injection moulding more sustainable?

Worried about the environmental footprint of plastic molding? Energy consumption and material waste are significant concerns needing proactive solutions in modern manufacturing operations.

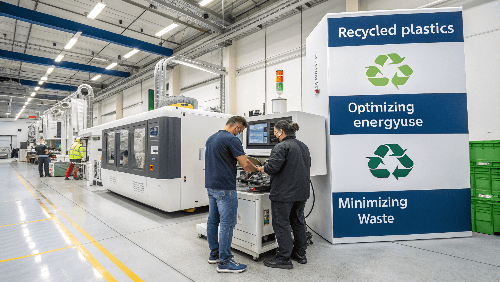

Make molding greener by using recycled/bio-plastics, reducing material via DFM (thin-walling, coring), optimizing energy use (all-electric machines, efficient processes), minimizing waste (regrind, hot runners), and designing for end-of-life recyclability.

Sustainability is becoming a major focus, and thankfully, many DFM principles naturally align with greener manufacturing. Efficiency, reducing waste, and smart material usage are good for the planet and often good for the bottom line.Material Selection & Reduction

- DFM for Less Material: Techniques like uniform thin-walling and using ribs/gussets instead of thick sections directly reduce the amount of plastic needed per part. This is often the biggest win.

- Recycled Content: Incorporate Post-Consumer Recycled (PCR) or Post-Industrial Recycled (PIR)/regrind where feasible. Requires careful validation.

- Bio-based Options: Explore polymers derived from renewable resources, considering their performance and end-of-life implications.

Energy Efficiency Gains

- DFM Enables Efficiency: Parts designed for easier flow and faster cooling require less energy-intensive processing (lower pressures, shorter cycle times).

- Modern Machines: All-electric injection molding machines consume significantly less energy than older hydraulic units.

- Process Optimization: Fine-tuning parameters minimizes energy consumption per cycle.

Waste Minimization Techniques

- Regrind: Carefully controlled reuse of runners and scrap parts reduces virgin material consumption.

- Hot Runners: Eliminate runner waste entirely, saving material and often cycle time, though mold cost is higher. DFM can influence the feasibility of hot runners.

- Defect Prevention: Good DFM and process control minimize scrap in the first place.

Design for End-of-Life

Consider how the part will be recycled. Use single material types where possible, avoid non-recyclable fillers or coatings, and incorporate markings to identify the plastic type. DFM plays a role in making disassembly easier if needed.

Conclusion

Applying DFM principles isn’t optional for efficient injection molding. It directly improves quality, cuts costs, speeds up production, and boosts sustainability. Start optimizing your designs with manufacturing in mind today.

-

Understanding DFM can help you design parts that are easier and more cost-effective to manufacture, saving time and money. ↩

-

Exploring best practices in injection molding can enhance your production efficiency and reduce defects, leading to better outcomes. ↩

-

Understanding the significance of uniform wall thickness can help prevent defects and improve the quality of molded parts. ↩

-

Exploring the role of draft angles can enhance your knowledge of effective mold design and improve production efficiency. ↩

-

Learn how uniform wall thickness can enhance product quality and reduce manufacturing issues, leading to better end-user experiences. ↩

-

Discover the significance of proper gating in ensuring product integrity and reducing defects during the manufacturing process. ↩