Injection molding is powerful, but are its drawbacks holding you back? High costs, long waits, and design limits can frustrate even experienced designers and stall production schedules.

Modern technologies like advanced simulation1, all-electric machines, automation, and innovative tooling2 are directly addressing traditional injection molding disadvantages. They improve efficiency, reduce costs, shorten lead times, and enhance part quality.

Injection molding is fantastic for mass production, turning out millions of identical parts cost-effectively. I built my career on its capabilities. But let’s be honest, it’s not without its challenges, especially when you’re starting a project or need flexibility. Designers like Jacky constantly balance the ideal design with the practical realities and costs of molding. Understanding these downsides is the first step to seeing how new approaches are making a difference.

What are the disadvantages of injection molding?

Dreaming of mass production but hit by the sticker shock of tooling? The initial hurdles of injection molding often involve high costs and long waits, delaying your product launch.

The main disadvantages are high initial mold costs, long tooling lead times (weeks or months), design restrictions (draft angles, wall thickness), and inflexibility for low-volume production or frequent design changes.

!

These aren’t minor issues; they significantly impact project planning and budgeting. I remember early projects where the tooling cost alone was a major hurdle for clients. It forces a high degree of certainty in the design before committing significant capital. Let’s break down why these factors are challenging:

Understanding the Key Drawbacks

| Disadvantage | Explanation | Impact for Designers (like Jacky) |

|---|---|---|

| High Initial Tool Cost | Molds are complex, precision-made tools from hardened steel, requiring skilled labor and machining time. | Requires significant upfront investment; mistakes are costly to fix. |

| Long Lead Times | Designing, manufacturing, and testing a mold takes considerable time, often 6-12 weeks or more. | Delays time-to-market; difficult for tight project deadlines. |

| Design Restrictions | Parts need specific features for moldability (draft, uniform walls, no undercuts without complex actions). | Limits design freedom; requires DFM knowledge to avoid issues. |

| Volume Inflexibility | Setup costs and tooling amortization make it inefficient for very small runs (prototypes, niche products). | Less suitable for initial testing or highly customized products. |

| Potential Material Waste | Runners and sprues in cold runner systems represent wasted material unless properly managed (regrind). | Adds material cost and environmental concerns if not addressed. |

These factors mean injection molding demands careful planning and a commitment to a specific design, making it less agile than some alternatives for early-stage development.

What are the advantages and disadvantages of all electric injection molding machines?

Using older hydraulic machines that are noisy, messy, and energy-hungry? These traditional workhorses have limitations compared to newer, more precise electric alternatives.

All-electric machines offer superior precision, repeatability, energy efficiency, and cleaner operation. However, they typically have a higher purchase price and may have limitations in maximum clamp tonnage compared to hydraulics.

The shift towards all-electric machines is one of the biggest technological advancements I’ve seen in molding operations. While hydraulics still have their place, especially for very large parts needing massive clamping force, electric machines offer compelling benefits for many applications, particularly in markets like consumer electronics where Jacky works.

Electric vs. Hydraulic: A Comparison

| Feature | All-Electric IM Machine | Traditional Hydraulic IM Machine | Notes |

|---|---|---|---|

| Precision | Very high, digital servo control | Good, but less precise flow control | Better for tight tolerances, complex parts. |

| Repeatability | Excellent, consistent shot-to-shot | Good, but subject to oil variations | Crucial for quality control in large runs. |

| Energy Efficiency | Significantly lower (up to 70% less) | Higher energy consumption | Lower operating costs, more sustainable. |

| Noise Level | Much quieter operation | Noisier due to hydraulic pumps | Improved work environment. |

| Cleanliness | No hydraulic oil = cleaner | Risk of oil leaks/contamination | Important for medical or food-grade molding. |

| Maintenance | Generally lower (no oil, fewer components) | Requires hydraulic system upkeep | Reduced downtime and maintenance costs. |

| Upfront Cost | Higher | Lower | The main disadvantage of electric machines. |

| Clamp Force | Max tonnage can be lower than hydraulics | Very high tonnage achievable | Hydraulics may be needed for very large parts (e.g., automotive). |

For designers like Jacky focused on quality and consistency, the precision and repeatability of electric machines are major advantages, helping to minimize variations and defects directly linked to process inconsistencies. The energy savings also contribute to lower long-term costs and sustainability goals.

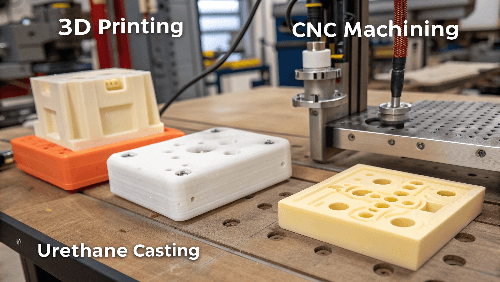

What is the best alternative to injection molding?

Need parts fast for prototyping or low volumes, but facing injection molding’s cost/time barriers? Sticking with IM when it’s not the right fit leads to wasted resources and delays.

The "best" alternative depends heavily on volume, material needs, complexity, and budget. Key options include 3D Printing (prototypes/low vol), CNC Machining (prototypes/high precision), and Urethane Casting (low-mid volume).

While injection molding excels at scale, it’s not always the right tool, especially early on or for smaller runs. I often advise clients to consider these alternatives based on their specific project stage and requirements. There’s no single "best" – it’s about choosing the most appropriate technology for the job at hand.

Exploring Viable Alternatives

- 3D Printing (Additive Manufacturing):

- Pros: Very fast for single parts/prototypes, excellent for complex geometry, no tooling cost, allows easy design iteration.

- Cons: Can be slow and costly for higher volumes, material properties might differ from final molded parts, surface finish often requires post-processing.

- Best For: Functional prototypes, concept models, very low volume custom parts, bridging the gap while IM tools are made.

- CNC Machining (Subtractive Manufacturing):

- Pros: High precision, wide range of "real" engineering materials (plastics and metals), no expensive tooling required for the part itself.

- Cons: Can be slower per part than molding, generates material waste (chips), geometric limitations (undercuts difficult), can be costly for complex parts in volume.

- Best For: High-fidelity prototypes in production materials, jigs/fixtures, low-volume production runs where tooling is prohibitive.

- Urethane Casting (or Vacuum Casting):

- Pros: Lower tooling cost (silicone molds) than injection molding, good for low-to-mid volumes (tens to hundreds), simulates molded part look/feel well, faster tooling than IM.

- Cons: Slower cycle time per part than IM, limited mold life, material options are thermoset urethanes (may differ from thermoplastic IM materials).

- Best For: Marketing samples, functional testing batches, low-volume production where IM isn’t justified.

Understanding these options allows designers like Jacky to choose the most effective path for prototypes and early production, potentially using 3D printing or CNC for initial validation before committing to expensive injection mold tooling.What other modern technologies help overcome IM disadvantages?

Are high costs and long lead times still a concern even with better machines? Relying solely on electric machines isn’t enough; other innovations are needed to fully tackle traditional IM hurdles.

Simulation software (Moldflow), advanced tooling (conformal cooling, better materials/coatings), automation/robotics, and improved hot runner systems significantly mitigate injection molding’s disadvantages by optimizing design, speeding cycles, reducing waste, and improving consistency.

Beyond the molding machine itself, a whole ecosystem of technologies works together to make injection molding faster, cheaper, and better. These tools empower designers and manufacturers to predict and prevent problems, streamline production, and squeeze more efficiency out of the process. I’ve seen these technologies transform how we approach mold design and production.Key Supporting Technologies:

- Mold Filling Simulation (e.g., Moldflow, Moldex3D):

- Benefit: Allows designers like Jacky to test and optimize part design for moldability before cutting steel. Predicts fill patterns, pressures, cooling, warpage, and potential defects like sink marks or air traps.

- Impact: Reduces costly tooling rework, shortens development time, helps optimize gate locations and process parameters, addresses Jacky’s challenge with shrinkage prediction.

- Advanced Tooling Techniques & Materials:

- Benefit: Conformal cooling channels follow the part’s shape for faster, more uniform cooling, reducing cycle times and warpage. Advanced tool steels and surface coatings increase mold life and reduce maintenance.

- Impact: Faster production, better part quality (dimensional stability), lower long-term tooling costs.

- Automation & Robotics:

- Benefit: Robots handle part removal, degating, inspection, and packing consistently and quickly, 24/7.

- Impact: Increased throughput, improved consistency (less human error), reduced labor costs, enables "lights-out" manufacturing.

- Hot Runner Systems:

- Benefit: Eliminate the cold runner (material pathway frozen each cycle), reducing material waste and often enabling faster cycle times and more flexible gating options.

- Impact: Significant material savings (especially with expensive resins), reduced cycle time, improved part cosmetics, lower part cost despite higher initial tool cost.

These technologies, often used in combination, tackle the core disadvantages of cost, time, and quality constraints, making injection molding a more refined and efficient process than ever before.Conclusion

While injection molding has inherent challenges like cost and lead time, modern tech like electric machines, simulation, automation, and advanced tooling effectively minimizes these downsides, boosting efficiency and quality.