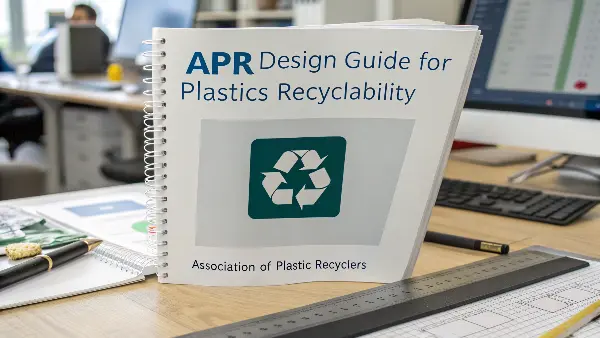

Navigating Global Plastic Recycling Regulations: What Do Manufacturers Need to Know?

Feeling overwhelmed by the complex web of global plastic recycling rules? Non-compliance can lead to hefty fines and restricted market access, hurting your business goals