Budgeting for injection molding feels overwhelming, right? Underestimate the costs, and your project could stall before it even starts, a common trap many fall into.

Budgeting involves summing costs for mold design and fabrication (tooling), plastic resin materials, machine time (hourly rate based on tonnage), labor (setup, operation, QC), and potential secondary operations. Key variables greatly influence the final price.

Understanding the full cost picture1 is critical before you commit. It’s not just about the price of the mold; materials, machine time, and labor add up significantly over a production run. I’ve seen promising projects hit major roadblocks because the initial budget only focused on the tooling. Let’s break down each cost element2 so you can build a realistic budget3 from the get-go and avoid nasty surprises down the line, ensuring designers like Jacky can plan effectively.

How Much Does the Injection Mold Itself Actually Cost?

Worried about that big tooling invoice? The mold cost is often the largest upfront investment, and quotes can vary wildly, making it hard to budget accurately if you don’t know the drivers.

Injection mold costs range dramatically, typically from $3,000 for simple, low-volume molds to over $100,000 for complex, high-cavitation, hardened steel tools. Key factors include part size, complexity, material, required lifespan (volume), and mold maker location.

The mold, or tooling, is where a huge chunk of the initial budget goes. There’s no single answer to "how much," because it depends entirely on what you need. I’ve worked on projects spanning this entire cost spectrum. Here’s what drives that price tag:

- ### Part Size and Complexity: Bigger parts need bigger molds, which means more steel and more machining time – both increase cost. Complex features like undercuts (requiring side actions/lifters), tight tolerances, intricate textures, or thin walls demand more sophisticated mold designs and precise manufacturing, pushing the price up significantly.

- ### Mold Material and Required Lifespan: As we discussed previously, the expected production volume dictates the mold material. A Class 105 aluminum prototype mold (<500 shots) is far cheaper than a Class 101 hardened H13 steel mold (>1 million shots). Higher quality, more durable materials cost more initially but are necessary for high volume.

- ### Number of Cavities: A mold can have one cavity (making one part per cycle) or multiple cavities (making several parts per cycle). Multi-cavity molds cost much more upfront but reduce the per-part cost during production because you get more parts per machine hour. Deciding the optimal cavitation requires balancing tooling budget against production volume and per-part cost targets.

- ### Mold Maker Location: Tooling costs can vary significantly based on geography due to differences in labor rates, overhead, and material costs. Building a mold in North America or Western Europe is generally more expensive than in Asia, though factors like communication, shipping, and quality control need careful consideration.

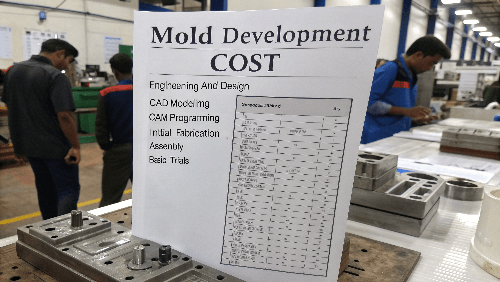

What’s Included in ‘Mold Development Cost’?

Does the mold quote seem high? Understanding what "development" entails helps clarify the value packed into that initial tooling price, preventing sticker shock from hidden engineering steps.

Mold development cost typically covers the detailed engineering and design work (including DFM analysis), CAD modeling of the mold components, CAM programming for machining, initial fabrication, assembly, and basic T0/T1 trials. It’s usually bundled into the total mold price.

"Mold development" isn’t just about cutting steel; it’s the entire process of translating your part design into a functional production tool. This phase is critical and involves significant expertise. When you get a mold quote, it generally encompasses these development stages:

- ### Design for Manufacturability (DFM): This crucial upfront analysis reviews your part design for potential molding issues (e.g., draft angles, wall thickness, undercuts) and suggests modifications to improve moldability and reduce costs. Skipping or rushing DFM often leads to problems and higher costs later. I always insist on a thorough DFM review.

- ### Mold Design & Engineering: Experienced designers use specialized CAD software to create the detailed 3D model of the mold itself. This includes designing the cavity and core, feed system (sprue, runners, gates), ejection system, cooling channels, and any necessary mechanisms like slides or lifters. This requires deep knowledge of molding principles.

- ### CAM Programming & Machining: Computer-Aided Manufacturing (CAM) software translates the mold design into instructions for CNC machines (milling, turning, grinding, EDM) that cut and shape the various steel components of the mold.

- ### Fitting, Assembly & Polishing: Skilled mold makers carefully assemble the machined components, ensuring precise fits and smooth operation. Cavity surfaces are often polished to achieve the desired part finish. This handwork requires significant skill.

- ### Initial Trials (T0/T1): The first test shots run in an injection molding machine to verify the mold functions correctly, check part dimensions, and identify any necessary adjustments (tuning). The cost of these initial trials is usually included in the mold price.

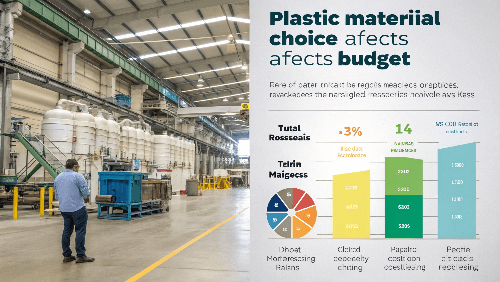

How Does Plastic Material Choice Affect Your Budget?

Think material cost is minor? While plastic seems cheap per pound, the sheer volume needed for production runs, plus the cost difference between resin types, significantly impacts the final per-part cost.

Material cost is calculated per part based on the plastic resin type (commodity vs. engineering grade), any additives (colorants, fillers), and the total shot weight (part weight plus runner/sprue system). Resin prices vary significantly.

After the mold, the raw plastic material is the next major ongoing cost. Don’t underestimate this! Here’s the breakdown:

- ### Resin Type: This is the biggest material cost driver.

- Commodity Plastics: Polypropylene (PP), Polyethylene (PE), Polystyrene (PS) are relatively inexpensive ($1-$3 per kg range, roughly).

- Engineering Plastics: Polycarbonate (PC), ABS, Nylon (PA), Acetal (POM) offer better performance (strength, temperature resistance) but cost more ($3-$10+ per kg).

- High-Performance Plastics: PEEK, PEI (Ultem), Liquid Crystal Polymers cost significantly more ($50-$100+ per kg) and are used for demanding applications.

- ### Additives and Colorants: Adding color concentrates, UV inhibitors, flame retardants, glass fibers, or other fillers increases the cost per kilogram of the material. Custom colors often cost more than standard black or natural.

- ### Shot Weight: The cost per part is determined by the total weight of plastic injected per cycle (the "shot weight"), which includes the finished part(s) plus the sprue and runner system that delivers plastic to the cavities. Multiply this shot weight by the cost per kg of your chosen material to get the material cost per cycle. Efficient runner design and using regrind (re-ground runner material, where feasible) can help minimize this. Market prices for resins also fluctuate, so factor that possibility into long-term budgeting. Buying in larger quantities usually secures a better price per kg.

What Are the Labor and Service Costs in Injection Molding?

Got your mold and material? You still need someone to actually make the parts. Labor for setup, running the machine, and quality checks is a significant part of the production cost per piece.

Labor and service costs include machine setup time, hourly wages for operators running the press, quality control inspections, part handling/packing, and general factory overhead. These are often factored into the machine’s hourly rate or charged per part.

Simply having the mold doesn’t get you parts; you need skilled labor and machine time. These costs are incurred during the actual production runs:

- ### Machine Setup: Before production starts, a technician needs to install the mold into the injection molding machine, connect cooling lines, set up any auxiliary equipment, and dial in the correct processing parameters (temperatures, pressures, speeds, times). This setup time costs money (labor + machine time) and is usually amortized over the production run quantity. Larger runs mean lower setup cost per part.

- ### Machine Operation: While modern machines are highly automated, they often require an operator to oversee the process, handle parts, perform basic visual checks, refill material hoppers, and respond to any alarms or issues. Operator wages contribute to the hourly cost. Sometimes one operator manages multiple machines.

- ### Quality Control: Depending on the part’s requirements, additional labor might be needed for more detailed quality checks, measurements, testing, or record-keeping beyond basic visual inspection.

- ### Part Handling and Packing: Removing parts from the machine area, potentially performing minor secondary operations (like trimming gates), and packing them into boxes requires labor time.

- ### Overhead: The molding facility has overhead costs (rent, utilities, management, support staff) that are factored into the overall service cost, typically as part of the machine hourly rate.

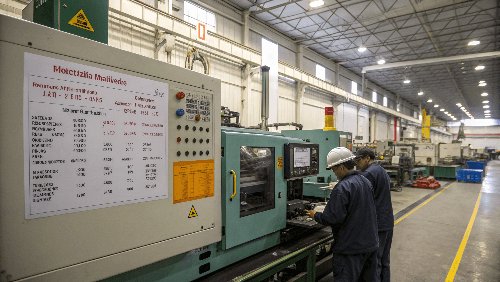

How Does Machine Time Factor into Injection Molding Costs?

Why are machine hourly rates different? The cost isn’t just electricity; it reflects the machine’s size, capabilities, depreciation, maintenance, and the floor space it occupies, all contributing to the per-part cost.

Machine time is charged per hour, based primarily on the press’s clamping force (tonnage). Rates cover machine depreciation, energy consumption, maintenance, and factory overhead. Larger machines needed for bigger parts have higher hourly rates.

The injection molding machine itself represents a significant capital investment for the molder, and running it costs money every hour. This cost is passed on to you as a machine hourly rate. Here’s what influences that rate:

- ### Machine Tonnage: The primary factor is the machine’s size, measured by its clamping force in tons. Larger parts require molds that need higher clamp force to stay closed during injection, meaning bigger, more expensive machines. A 50-ton press might have a rate of $40-$60/hour, while a 500-ton press could be $80-$150+/hour (these are rough examples, rates vary widely by region and facility). Your part size dictates the minimum tonnage required.

- ### Cycle Time: While not directly part of the rate, the cycle time (time to make one shot) is critical. A lower cycle time means more parts produced per hour, reducing the machine cost allocated to each individual part. Optimizing cycle time is key to cost efficiency.

- ### Energy Consumption: These machines use significant amounts of electricity to heat the plastic and power the hydraulics or electric motors.

- ### Maintenance & Depreciation: Machines require regular maintenance, and their purchase cost is depreciated over their lifespan. These costs are built into the hourly rate.

- ### Automation & Auxiliaries: If the process requires robots for part removal, specialized dryers for materials, or complex cooling systems, these can sometimes influence the effective hourly cost.

What Key Variables Influence Your Total Injection Molding Budget?

Feeling like costs are a moving target? Several key factors interact to determine the final price, and understanding them helps you make informed decisions during design and quoting to manage the budget.

The most significant variables impacting total cost are part complexity, plastic material choice, required production volume (affecting mold type and amortization), mold cavitation, surface finish quality, tolerance requirements, and the geographical location of the mold maker and molder.

Budgeting isn’t about isolated costs; it’s about how different factors interact. Small changes in one area can ripple through the entire budget. When I work with clients like Jacky, we always review these key variables: |

Variable | Impact on Cost | Why? |

|---|---|---|---|

| Part Complexity | Increases mold cost, potentially cycle time | More features (undercuts, threads) = complex mold, difficult ejection/cooling | |

| Material Choice | Affects material cost/part, mold material choice | Engineering resins cost more; abrasive/corrosive resins need better, costlier steel | |

| Production Volume | Affects mold class/cost, per-part cost | Higher volume justifies better mold; amortizes setup/tooling over more parts | |

| Cavitation | Higher mold cost, lower per-part cost/machine time | More parts per machine cycle increases throughput | |

| Surface Finish | Increases mold cost (polishing), may need better steel | Higher finishes (e.g., SPI-A1) require significant labor, specific steels | |

| Tolerances | Increases mold cost, potentially QC cost | Tighter tolerances require precision machining, more rigorous inspection | |

| Location | Affects mold cost, labor rates, logistics | Significant regional differences in labor, overhead, steel, shipping costs |

Understanding how these factors play together is essential. For example, a high-volume project might justify a more expensive multi-cavity, hardened steel mold built overseas to achieve the lowest possible per-part price, while a low-volume, complex part might be better suited to a single-cavity P20 mold built locally, even if the per-part price is higher.

What Kind of Profit Margin Can Molders Expect?

Trying to gauge if a quote is fair? While molders need to make a profit, understanding the typical range and what drives it helps you assess whether a quote is reasonable or potentially inflated.

Injection molding profit margins vary widely (often 10-30%+) depending on operational efficiency, run volume, part complexity, competition, overhead, and any value-added services offered. There isn’t one standard margin.

It’s natural to wonder about the molder’s profit when you receive a quote. While it’s impossible to know their exact numbers, understanding the factors that influence profitability provides context. Margins aren’t fixed; they depend heavily on:

- ### Operational Efficiency: Shops with modern, well-maintained equipment, good process control, automation, and lean manufacturing practices can often operate more profitably, potentially allowing them to offer more competitive pricing.

- ### Volume and Specialization: High-volume commodity parts might have lower margins per piece but generate significant overall profit through sheer quantity. Conversely, highly complex parts, difficult materials, or specialized services (like cleanroom molding, overmolding, insert molding) typically command higher profit margins due to the increased expertise and risk involved.

- ### Competition: In highly competitive markets, molders might operate on tighter margins to win business.

- ### Overhead Structure: A molder’s own costs (facility, non-production staff, utilities) impact their required margin.

- ### Value-Added Services: If the molder provides additional services like DFM assistance, assembly, specialized packaging, inventory management, or logistics, they will factor the cost and a reasonable profit for these into the overall price. It’s not just about machine time; it’s the whole service package.

Are There Any Reliable ‘Rules of Thumb’ for Molding Costs?

Looking for a quick shortcut to estimate costs? While tempting, simple rules of thumb for injection molding costs are often inaccurate and can lead to significant budget errors if relied upon too heavily.

Be very cautious with rules of thumb (e.g., cost per cavity, cost based on weight). They rarely account for critical variables like complexity, material, or tolerances. Focusing on DFM principles is a more reliable ‘rule’ for cost reduction.

Everyone loves a simple rule of thumb for quick estimates, but in injection molding, they can be dangerously misleading. I’ve seen budgets based on these shortcuts fall apart quickly. Here’s why common ones often fail:

- Cost per Cavity: This ignores huge variations in complexity. A simple bottle cap cavity costs vastly less than a complex electronics housing cavity of the same size.

- Cost vs. Part Weight/Size: While size matters, complexity and material type often have a greater impact on mold cost than sheer volume. Material cost per part relates to weight, but tooling and cycle time don’t always scale linearly.

- Mold Cost ≈ X times Annual Part Value: This is highly variable and depends entirely on volume, part price, and required mold life.

A Better "Rule": Instead of arbitrary cost formulas, the most reliable "rule" is to rigorously apply Design for Manufacturability (DFM) principles from the very beginning. Focusing on aspects like:- Uniform wall thickness

- Adequate draft angles

- Avoiding unnecessary undercuts

- Simplifying geometry where possible

- Choosing appropriate tolerances

These design choices reliably reduce mold complexity, improve moldability, shorten cycle times, and therefore lower both tooling and production costs. Getting multiple, detailed quotes based on a well-defined specification is always the best approach for accurate budgeting.

Need Lower Volumes? What Are Cheaper Alternatives to Injection Molding?

Is the injection mold cost prohibitive for your needs? If you only require prototypes or low production quantities, several alternative manufacturing methods offer lower upfront investment, avoiding high tooling costs.

For prototypes or low volumes (<1000 parts), consider 3D Printing (FDM, SLA, SLS), Urethane Casting (using silicone molds), or CNC Machining directly from plastic stock. These avoid the high cost of steel tooling.

Injection molding excels at high-volume production due to its low per-part cost once the expensive mold is made. But if you only need a handful, hundreds, or even just a few thousand parts, that initial tooling cost can be impossible to justify. Thankfully, there are excellent alternatives, particularly for prototypes or initial low-volume runs:

- ### 3D Printing:

- Technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF).

- Pros: No tooling cost, very fast turnaround (days), good for complex geometries, various material options (though may differ from final injection molding material).

- Cons: Higher per-part cost, potentially weaker parts (depending on tech), surface finish might require post-processing.

- Best for: 1-100s of parts, functional prototypes, design verification.

- ### Urethane Casting (Vacuum Casting):

- Process: Uses a 3D printed master pattern to create a silicone mold, which is then used to cast urethane parts.

- Pros: Lower tooling cost than steel ($500-$2000 range typically), good surface finish mimicking molded parts, faster than injection mold tooling, can simulate various plastic properties.

- Cons: Silicone molds have limited life (typically 15-30 shots per mold), per-part cost higher than injection molding, limited material choices (urethanes, some silicones).

- Best for: 10s to low 100s of parts, high-fidelity prototypes, marketing samples, first pilot runs.

- ### CNC Machining:

- Process: Directly cutting parts from a solid block of plastic (or metal).

- Pros: Uses actual production-grade plastics, high precision, good surface finish.

- Cons: Can be slow and expensive per part, especially for complex geometries; generates material waste; limitations on internal features.

- Best for: 1-100s of parts, functional testing with specific materials, simpler geometries, jigs/fixtures.

Conclusion

Budgeting accurately for injection molding requires looking beyond the initial mold quote. You must factor in material costs, machine time, labor, and understand how variables like volume and complexity impact the total project investment from design through production.

-

Understanding the full cost picture is essential for effective budgeting in manufacturing projects. Explore this link to gain insights. ↩

-

Identifying key cost elements is crucial for accurate budgeting. This link provides a detailed breakdown of these elements. ↩

-

Creating a realistic budget helps avoid unexpected costs and ensures project success. Check this resource for practical tips. ↩