How Can You Effectively Budget for Injection Molds from Prototype to Production?

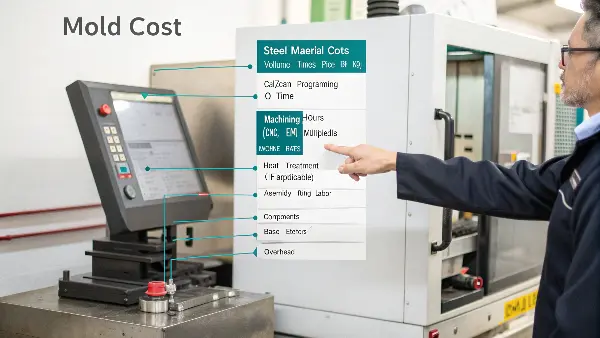

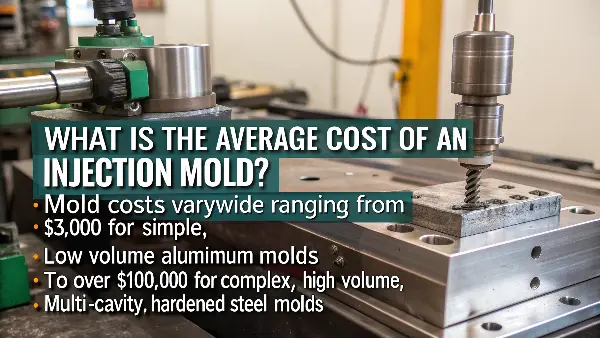

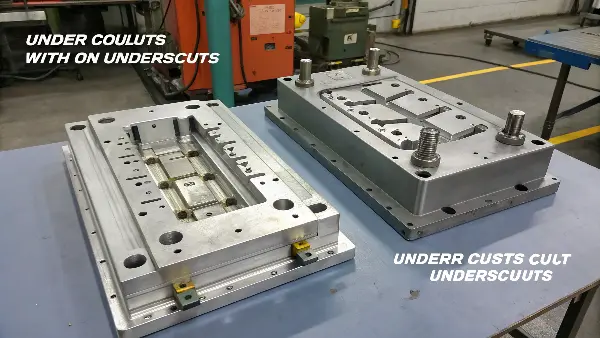

Struggling to estimate injection mold costs accurately? Budget mistakes can sink projects before they start, leading to unexpected expenses or compromised quality. Let’s clarify the