Customers asking for eco-friendly options1? Ignoring sustainability trends risks losing market share and brand reputation. You need clear strategies to meet this growing demand effectively.

Yes, consumer demand for sustainable products, including plastics, is rapidly increasing. Manufacturers must adapt by incorporating recycled materials2, exploring bioplastics, and designing for recyclability to stay competitive.

It’s clear sustainability isn’t just a buzzword anymore; it’s a core expectation. As manufacturers and mold makers at CavityMold, we see this shift firsthand. Our clients, including skilled designers like Jacky, often discuss the pressure to find greener solutions that still perform flawlessly and meet budget constraints. So, how strong is this demand, and how can manufacturers realistically meet it?

Are consumers demanding sustainable products?

Feeling unsure if sustainability truly drives purchasing decisions? Ignoring this trend could mean missing out on a significant and growing customer base looking for eco-conscious choices from brands they trust.

Absolutely. Numerous studies and market trends show a clear and growing consumer preference for sustainable products. Buyers actively seek brands committed to environmental responsibility, influencing purchasing across many sectors.

Diving Deeper: Understanding Consumer Priorities

The evidence is overwhelming. Market research firms consistently report a strong consumer desire for sustainable options. Reports from companies like Nielsen (now NIQ) and others regularly show that a majority of global consumers consider sustainability when making purchases. They are often willing to change their buying habits to reduce environmental impact. Younger generations, like Millennials and Gen Z, are particularly vocal and influential in driving this trend. They grew up with more awareness of issues like climate change and plastic pollution. This awareness translates directly into purchasing power. Consumers want transparency3. They look for clear labeling, information about recycled content, ethical sourcing, and a brand’s overall environmental commitment4. For designers like Jacky, this isn’t just about materials anymore. It means thinking about sustainability from the very start of a project – designing for durability, potential disassembly, and eventual recycling or responsible disposal. Ignoring this demand is no longer an option for brands that want to stay relevant and competitive. We see companies actively promoting their sustainability efforts because they know it matters to their customers.

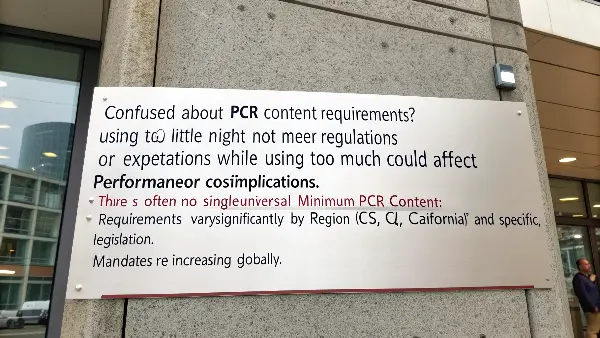

What is the minimum PCR content?

Confused about Post-Consumer Recycled (PCR) content requirements? Using too little might not meet regulations or expectations, while using too much could affect performance or cost implications.

There’s often no single universal minimum PCR content. Requirements vary significantly by region (e.g., EU, California), product type (e.g., packaging, beverage bottles), and specific legislation. Mandates are increasing globally.

Diving Deeper: Navigating PCR Mandates and Goals

The push for a circular economy is leading governments worldwide to set specific targets for PCR content, especially in packaging. It’s crucial to understand that these rules are not uniform.

- Regulatory Examples:

- The European Union’s Packaging and Packaging Waste Regulation (PPWR) proposals include ambitious targets for minimum recycled content in various plastic packaging formats, scheduled to increase over time.

- In the United States, California’s Assembly Bill 793 mandates increasing levels of PCR content in plastic beverage containers sold in the state. Other states are following with similar legislation.

- Beyond Mandates: Many companies aren’t just waiting for laws. They set their own ambitious, voluntary targets for PCR use to demonstrate leadership and meet consumer expectations. Initiatives like the Global Commitment led by the Ellen MacArthur Foundation encourage major brands to increase PCR usage significantly.

- Practical Challenges: Achieving high PCR levels involves practical hurdles.

- Supply: Is there a consistent supply of high-quality PCR material for the specific type of plastic needed (e.g., food-grade rPET, clear rPP)? Supply chains are still developing.

- Performance: Incorporating PCR can sometimes affect the material’s properties – color might shift, mechanical strength could slightly decrease, or processing parameters might need adjustment. Jacky would need test data on how PCR affects things like mold flow and final part tolerances. Food-contact applications require PCR materials that meet stringent safety regulations.

- Cost: While sometimes cheaper, high-quality PCR can occasionally be more expensive than virgin plastic due to collection, sorting, and reprocessing costs.

Manufacturers must research the specific regulations for the product type and the geographical markets where it will be sold. Staying informed is key.Are consumers willing to pay more for sustainable products Nielsen?

Worried that using sustainable materials will price your products out of the market? Assuming consumers won’t pay extra could mean underestimating their commitment to eco-friendly options5 and losing potential revenue.

Yes, Nielsen studies6 consistently show a significant percentage of global consumers are willing to pay more for products from sustainable brands. This willingness varies by demographic, region, and product category.

Diving Deeper: The Economics of Sustainability

The idea that consumers prioritize price above all else is becoming outdated, especially regarding sustainability. Nielsen (NIQ) and other market researchers have tracked this for years.

- Consistent Findings: Reports frequently show that over two-thirds of global consumers say they are willing to pay more for sustainable products. This isn’t just talk; sales data for products marketed with sustainable attributes often show faster growth compared to conventional counterparts.

- Demographic Drivers: While widespread, the willingness is often strongest among younger consumers (Millennials and Gen Z) who prioritize environmental and social values. However, interest spans across age groups and income levels.

- The Premium Limit: Consumers aren’t usually willing to pay an unlimited amount more. The acceptable premium depends on the product, the perceived benefit of the sustainable feature (e.g., organic food vs. recycled packaging), and the price difference compared to alternatives. A modest, justified increase is generally more palatable.

- The Trust Factor: This willingness is heavily dependent on trust. Consumers need clear, credible information about a product’s sustainability features. Vague claims or "greenwashing" quickly erode trust and negate any willingness to pay more. Brands need to be authentic and transparent. At CavityMold, we help clients achieve cost-effective molding, but we also understand the value of using materials that genuinely support their sustainability story. Jacky knows his designs need to either visibly incorporate sustainable features or be backed by clear communication that resonates with these conscious consumers.

What are the sustainable plastics for products?

Overwhelmed by the different "sustainable" plastic options available? Choosing the wrong material might not align with your sustainability goals or could even cause production headaches or performance issues in the final product.

Sustainable plastics primarily include recycled plastics (PCR/PIR), bio-based plastics (derived from renewable resources like corn or sugarcane), and potentially biodegradable/compostable plastics (though end-of-life infrastructure is critical).

Diving Deeper: Choosing the Right Sustainable Plastic

| Selecting the most appropriate "sustainable" plastic requires careful consideration of several factors beyond just the label. Here’s a breakdown of the main categories: | Plastic Type | Description | Pros | Cons | Best Suited For… |

|---|---|---|---|---|---|

| Recycled (PCR/PIR) | Plastics recovered from consumer (PCR) or industrial (PIR) waste streams. | Reduces landfill waste, lowers carbon footprint vs. virgin, supports circular economy, meets mandates. | Availability/quality varies, potential cost fluctuations, color/clarity limitations, processing adjustments may be needed, food-grade requires specific sourcing. | Packaging, containers, automotive parts, textiles, construction materials where regulations or goals demand it. | |

| Bio-based Plastics | Derived wholly or partly from renewable biomass (corn, sugarcane, algae etc). | Reduces fossil fuel reliance, renewable source, some have lower production footprint (e.g., PLA). | Potential land/water use impact, competition with food sources, often higher cost, specific properties (e.g., PLA heat limit), end-of-life complexity (recycling/composting). | Single-use items (if compostable & infrastructure exists), packaging, textiles, durable goods (e.g., Bio-PET/PE). | |

| Biodegradable/ Compostable | Designed to break down under specific conditions (microbes, heat, humidity). | Can decompose into natural elements if conditions are met (usually industrial composting). | Requires specific disposal (industrial composting often lacking), can contaminate conventional recycling, "biodegradable" term can be misleading (no benefit in landfill). | Food service ware, bags intended for compost collection systems, agricultural films (where collection is difficult). |

Key Considerations for Selection:

- Application Needs: Match the material’s properties (strength, heat resistance, clarity) to the product’s requirements.

- End-of-Life Scenario: Where will the product likely be disposed of in its target market? Is industrial composting available? Is it likely to enter standard recycling streams?

- Regulations & Goals: Does the material help meet PCR mandates or company sustainability targets?

- Cost & Availability: Is the material readily available at a viable cost?

For a designer like Jacky, this means a complex decision matrix for every project, balancing technical needs with genuine environmental benefits and market realities.Conclusion

Meeting rising consumer demand for sustainable plastic products is essential. Success involves integrating recycled materials like PCR, exploring suitable bio-based alternatives, and designing products with their end-of-life in mind.

-

Explore this link to discover innovative eco-friendly solutions that can help your business meet consumer demand and enhance sustainability. ↩

-

Learn about the advantages of incorporating recycled materials into your production process to boost sustainability and appeal to eco-conscious consumers. ↩

-

Understanding the role of transparency can help brands connect better with consumers and build trust in their sustainability claims. ↩

-

This link will offer strategies for brands to showcase their environmental commitment, appealing to eco-conscious consumers. ↩

-

Learn about the rising popularity of eco-friendly options and how they impact consumer choices and market trends. ↩

-

Discover insights from Nielsen studies that reveal consumer behavior towards sustainable products and their willingness to pay more. ↩