how to calculate injection molding tonnage

Understanding how to calculate injection molding tonnage is crucial for anyone involved in the plastic manufacturing industry. This process ensures that the right amount of

Understanding how to calculate injection molding tonnage is crucial for anyone involved in the plastic manufacturing industry. This process ensures that the right amount of

Struggling to get your thin-wall parts right? Warping, short shots, and cracks are probably driving you crazy and costing you a ton of money and

Frustrated with TPU defects? Tiny parameter tweaks can make a huge difference. Get it right for flawless parts! Fine-tuning TPU injection molding involves meticulous control

Figuring out what makes a plastic injection molding machine "good" can feel like a maze, right? You’re looking for reliability, precision, and something that fits

Struggling with TPU? Choosing the wrong grade means poor performance. Get it right for top-quality parts. Selecting the right TPU hardness involves understanding your product’s

Finding the right plastic molding partner can feel like searching for a needle in a haystack, right? You’re worried about quality, deadlines, and costs, and

Finding a reliable plastic injection molding partner in China can feel like searching for a needle in a haystack, right? So many options, so much

Are your injection molding operations constantly hit by unexpected defects, causing frustrating delays and material waste? It’s a common headache when you can’t quickly pinpoint

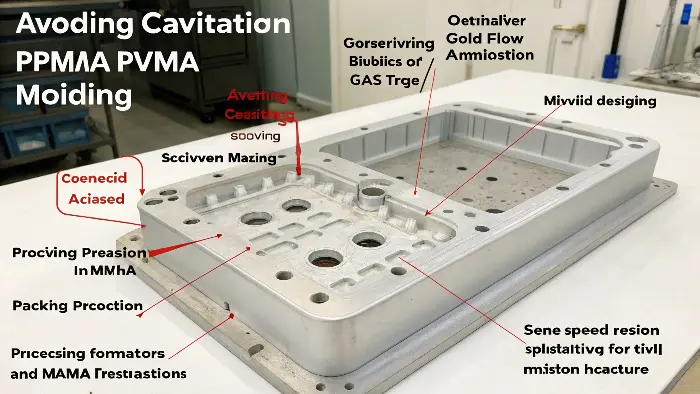

Struggling with PMMA parts that don’t meet spec? Precision is tough. CavityMold delivers flawless PMMA components, mastering the art of high-precision molding. CavityMold achieves high-precision

Worried about the environmental footprint of your PMMA projects? Traditional manufacturing can be resource-intensive. But what if there were ways to make it greener without

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”