How Is Precision Injection Molding Driving Success Across Industries?

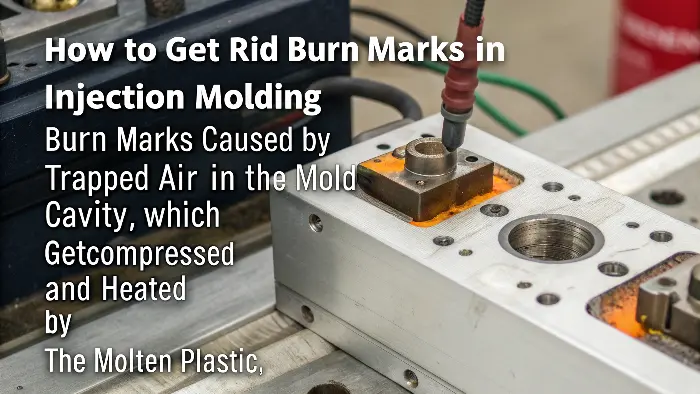

Are you struggling to get complex plastic parts made with the exactness your project demands? A small flaw can derail your entire production schedule, leading

Are you struggling to get complex plastic parts made with the exactness your project demands? A small flaw can derail your entire production schedule, leading

Choosing the right material for a product that needs to be soft, flexible, and durable can be a real headache. Make the wrong call, and

Are you struggling to select the right plastic for a demanding project? Picking the wrong material can lead to part failure, expensive re-tooling, and major

Struggling to get high-precision plastic parts right? Choosing the wrong material or a poor design can quickly lead to costly failures and project delays. This

Are you tired of seeing perfectly good production runs ruined by ugly sink marks on your thick-walled plastic parts? These defects spoil the look of

Are you struggling to choose the best manufacturing process for your high-performance auto parts? The wrong decision can lead to failed components, project delays, and

Picking the right manufacturing process for electronic connectors feels like a huge gamble. You know a wrong choice means blown budgets, project delays, and connectors

Choosing the wrong manufacturing process for a medical device enclosure can lead to costly delays and compliance headaches. Imagine your device failing critical tests because

Choosing the wrong manufacturing process for your power tool housings can be a disaster. It can lead to cracked parts, unhappy customers, and soaring production

Struggling to justify the high upfront cost of injection molding to your stakeholders? The initial sticker shock from a tooling quote can halt a project

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”