Are you pulling your hair out over a pile of rejected thin-wall parts? Short shots, warped pieces, and ugly flash can turn a profitable project into a money pit, fast. It feels like you’re just guessing, tweaking one setting after another with no real progress. But what if you had a clear, systematic guide to fix these exact problems?

The best way to troubleshoot thin-wall molding defects is to systematically investigate the four key areas: the material, the part design, the mold, and the processing parameters. For example, short shots often point to flow issues (process/material), while warpage is almost always a cooling or design problem (mold/part design). By isolating the likely cause, you can solve problems efficiently instead of just guessing.

I’ve been standing next to molding machines for over a decade, and I can tell you, everyone faces these issues. The difference between a pro and an amateur is how they approach the problem. It’s not about magic; it’s about being a good detective. I remember one project—a simple food container—that was giving us fits. We were getting all sorts of defects. Instead of panicking, we took a breath, grabbed a coffee, and started going through our checklist, one item at a time. Let’s walk through that same process for the most common headaches.

How Do You Fix Annoying Short Shots and Incomplete Fills?

There’s nothing more frustrating than opening the mold and finding a part that’s only 95% there. These "short shots" are pure scrap, and they’re a sign that your plastic isn’t making it to the end of the line. You’re literally throwing material and machine time in the bin with every cycle.

To fix short shots, you must improve the plastic’s ability to flow and fill the cavity before it freezes. The fastest way is to increase the injection speed or pressure. If that doesn’t work, try raising the melt or mold temperature. If the problem persists, the issue might be in the mold itself—like blocked vents or gates that are too small.

I once worked on a project for a medical device component, a very thin, long part. We were getting short shots right at the very end of the fill path. The operator kept cranking up the pressure, but it wasn’t helping. We took a closer look at the mold and realized the vents at the end of the part were almost completely clogged with residue. A five-minute cleaning job solved a problem they’d been fighting for hours. It’s not always about turning the dials up to 11.

Getting to the Root of Incomplete Fills

A short shot is a flow problem, plain and simple. The plastic stops moving before the cavity is full. The question is, why did it stop? It’s usually one of three things: the process, the mold, or the material.

-

Process Parameters: This is your first stop.

- Injection Speed/Pressure: Is it fast enough? Thin-wall molding is a race against time. You need to fill the part in a fraction of a second. Try increasing the injection speed first. If that’s maxed out, you may need more injection pressure to push the material through the thin sections.

- Temperatures: A hotter melt flows more easily. Try bumping up the barrel temperature by 5-10°C. A warmer mold also keeps the flow path open longer. But be careful—go too high and you can degrade the material or increase cycle time.

-

Mold Design & Maintenance: If process changes don’t work, look at the steel.

- Venting: This is a huge one. Trapped air acts like a roadblock. If air can’t get out, plastic can’t get in. Check that vents are present, open, and deep enough. They are often the first thing to get overlooked or clogged.

- Gates: Is the gate large enough to allow a high volume of material to enter the cavity quickly? A pinpoint gate might be starving the part.

Here’s a quick checklist to run through:

| Area to Check | Action Item | What It Solves |

|---|---|---|

| Process | Increase Injection Speed | Fills the mold faster before the plastic freezes. |

| Process | Increase Melt Temperature | Reduces plastic viscosity, making it flow easier. |

| Mold | Inspect and Clean Vents | Allows trapped air to escape, removing back-pressure. |

| Material | Verify MFI/MFR | Ensure you’re using a high-flow grade suitable for thin walls. |

What’s the Secret to Eliminating Warpage in Thin Parts?

You’ve solved your filling problems and are making complete parts. But now they come out of the mold looking like potato chips. This warpage makes assembly impossible and looks terrible. It’s one of the trickiest defects to solve because it has so many potential causes.

The secret to eliminating warpage is to manage stress by ensuring uniform cooling. First, check that your packing pressure isn’t too high or too low. Then, verify that the temperatures of both mold halves are balanced. If the problem persists, the root cause is likely non-uniform wall thickness in the part design or an inefficient cooling channel layout in the mold.

Warpage is all about stress. As plastic cools, it shrinks. If one part of your piece cools and shrinks faster than another, it creates internal stress that pulls and twists the part out of shape. I remember a project for a large, flat lid. It was warping so badly you could rock it like a seesaw. The problem? The cooling lines on the core side of the mold were running much hotter than on the cavity side. Once we balanced the water flow and got the temperatures within 5°C of each other, the parts came out perfectly flat.

Un-twisting the Warpage Problem

Think of warpage as a tug-of-war inside your part. Your job is to make sure the fight is even on all sides.

-

Part Design is King: Honestly, most severe warpage issues start here. The golden rule is uniform wall thickness. If you have a thick section connected to a thin section, the thick section will cool much slower and shrink more, pulling the thin section out of shape. Before you even cut steel, we use advanced simulation software to predict these issues. It allows us to see how the part will warp and make design changes—like adding ribs for stiffness instead of thickening a wall—to prevent it.

-

Mold Cooling: This is the next biggest factor. The cooling channels in your mold must be designed to remove heat evenly from the entire part. If one side cools faster, it will shrink first and cause warpage. This is where our expertise at CavityMOLD really comes in. We spend a ton of time designing and optimizing cooling layouts, sometimes using conformal cooling that follows the exact shape of the part to ensure total uniformity.

-

Process Tuning:

- Packing Pressure: This is your main tool at the machine. Too little packing pressure can lead to sinks and voids, but too much can induce a huge amount of stress into the part, which is then released as warpage after ejection. It’s a delicate balance.

- Cooling Time: Don’t be in a hurry to eject the part. If you pull it out when it’s still too hot and soft, it will warp as it finishes cooling in the open air. Make sure it’s rigid enough to hold its shape before ejecting.

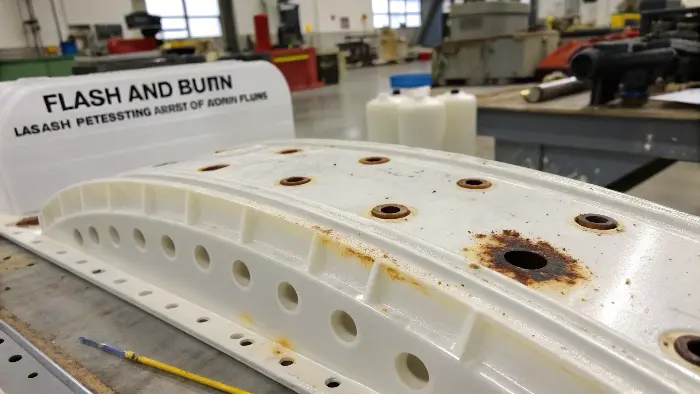

How Can You Get Rid of Flash and Burn Marks for Good?

Two other ugly defects that often appear together are flash and burn marks. Flash is that thin, unwanted film of plastic that squeezes out of the mold on the parting line. Burn marks are those nasty black or brown spots that show up on the part, usually at the end of the fill path. Both make the part look cheap and often require manual trimming, which costs time and money.

To fix flash, reduce the injection pressure or speed, and ensure your machine’s clamping force is high enough to hold the mold shut. For burn marks, the solution is to improve mold venting so trapped air can escape before it gets superheated and scorches the plastic. These two issues often have the same root cause: trying to inject too fast.

Flash and burns are signs that your process is out of control. Think of it like this: you’re pushing the plastic in so hard and fast that you’re either blowing the mold open (flash) or running over the air that’s trying to get out (burns). We had a client come to us with a mold for a small electronic housing that was flashing badly. They thought they needed a bigger machine with more clamp force. But we looked at their process—their injection speed was insane! We slowed it down just a little, and the flash disappeared. The problem wasn’t the clamp; it was the process.

Cleaning Up Your Process

Let’s tackle these two separately, even though their cause is often linked.

-

Fighting Flash:

- Check Your Clamp Tonnage: Is the machine strong enough to hold the mold shut against the injection pressure? Do a quick calculation:

Injection Pressure x Part Projected Area. If your clamp force is too low, the mold will be forced open. - Reduce Injection Pressure/Speed: This is the easiest fix. You might be pushing too hard, too fast.

- Inspect the Mold: Is the parting line damaged or worn? Are the mold plates flat? Any tiny gap can become a path for flash. At CavityMOLD, we build our molds with high-quality P20 steel and ensure perfect mating between the mold halves. This robust construction is our first line of defense against flash.

- Check Your Clamp Tonnage: Is the machine strong enough to hold the mold shut against the injection pressure? Do a quick calculation:

-

Eliminating Burn Marks:

- Improve Venting: This is the cause 99% of the time. Air needs a way out. When it’s compressed rapidly, its temperature skyrockets (this is called adiabatic compression—the same principle a diesel engine uses) and it burns the plastic. Check that your vents are deep enough (a common starting point is 0.01-0.03 mm) and are located at the last place the plastic fills.

- Slow Down the Injection Speed: If you can’t add more vents, slowing down the last part of the injection shot gives the air more time to escape through the existing vents.

Conclusion

Troubleshooting thin-wall defects doesn’t have to be a nightmare. By thinking like a detective and systematically checking the material, design, mold, and process, you can pinpoint the root cause and implement an effective solution. It’s about being methodical, not just randomly turning dials. This approach saves time, reduces scrap, and ultimately helps you Master Molding Right.