Feeling lost trying to budget for injection molds? Hidden costs and complexity can blow your budget unexpectedly. Let’s clarify exactly what drives your mold price with us.

Your injection mold cost1 is mainly set by part complexity2, size, material choice, required cavitation (number of parts per shot), mold steel type3, necessary precision (tolerances), and expected production volume. We evaluate these transparently.

Getting a clear quote is essential for project success. At CavityMold, we believe in open communication about pricing. Understanding how we arrive at the final figure helps you plan effectively, just like my client Jacky needs when designing new electronic components. Let’s explore the specifics together.

How Do We Calculate Your Injection Mold Cost?

Ever get a mold quote that feels like a black box? It’s hard to budget or compare options without knowing the breakdown. We calculate costs methodically for clarity.

We calculate mold cost by totaling estimated hours for design, machining (CNC, EDM, etc.), materials (steel, components), assembly, polishing, and initial sampling/tryout, plus a factor for overhead and predictable profit.

!

Diving Deeper: Breaking Down the Calculation Steps

Our goal is transparency, so here’s a look at how we build your quote piece by piece:

### Design and Engineering Hours:Before any metal is cut, our engineers review your part design (DFM – Design for Manufacturability), design the mold itself in CAD, and create detailed drawings. More complex parts or mold actions (like sliders or lifters) require more engineering time, increasing this cost component. We factor in the time needed for thorough design reviews to prevent issues later.### Material Costs:This includes the mold base, the core and cavity steel (P20, H13, S7, stainless variations, etc.), and any standard or specialized components like ejector pins, bushings, or hot runner systems if specified. Harder, more durable steels cost more upfront but offer longer mold life. The sheer size of the mold also directly impacts the amount of steel needed.### Machining and Manufacturing Hours:This is often the largest cost component. It covers the time spent on various machines: CNC milling for shaping cores/cavities, EDM (Electrical Discharge Machining) for intricate details or hard materials, grinding for precision surfaces, and drilling for cooling channels. Tighter tolerances demand slower machining speeds, more careful setups, and thus more hours.-

### Assembly, Polishing, and Tryout:Skilled toolmakers meticulously assemble all the mold components. Surface finish requirements dictate polishing time – a high-gloss finish takes significantly more manual effort than a standard textured finish. Finally, we conduct mold trials (tryouts) to test the mold, make adjustments, and ensure it produces parts to your specifications. This requires machine time, material, and labor.

Here’s a simplified view of the components:Cost Component Primary Driver(s) Example Activity Design/Engineering Part complexity, mold features Mold CAD design, DFM analysis Materials Mold size, steel type, components (hot runner) Purchasing steel block, mold base Machining Size, complexity, tolerances, steel hardness CNC milling core, EDM ribs Assembly/Finishing Number of components, surface polish level Fitting sliders, hand polishing cavity Tryout/Adjustments Ensuring part quality, process setup Running samples, measuring parts Overhead/Profit Business operations, quality systems, expertise Project management, quality assurance By evaluating each of these stages based on your specific project requirements, we build a detailed and fair cost estimate.

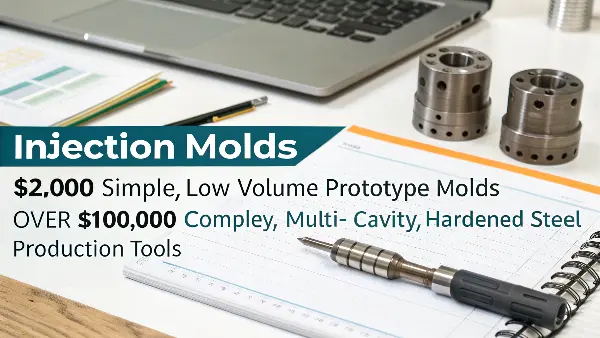

What’s the Typical Cost Range for an Injection Mold?

Need a starting point for your mold budget? Asking "how much" without context gets vague answers, delaying your planning. Let’s look at typical cost ranges we see.

Injection molds can range from around $2,000 for simple, low-volume prototype molds to well over $100,000 for complex, multi-cavitation, hardened steel production tools. Size, complexity, and material drive this wide variation.

Diving Deeper: Understanding the Spectrum of Mold Costs

The price tag on an injection mold isn’t arbitrary; it reflects the resources needed to create it. Here’s a general idea of what falls into different cost brackets:

### Simple, Low-Volume Molds (approx. $2,000 - $10,000):These are often single-cavity molds made from softer materials like aluminum or pre-hardened P20 steel. They are suitable for prototyping or very low production runs (hundreds to a few thousand parts). The part designs are typically simple, without complex undercuts or tight tolerances. Manual or very basic ejection systems might be used. Think simple enclosures, caps, or brackets.### Medium Complexity/Volume Molds (approx. $10,000 - $50,000):This is a common range for many industrial and consumer parts. These molds might have multiple cavities (2-8), use hardened steels (like H13) for longer life (tens to hundreds of thousands of cycles), incorporate simple sliders or lifters for undercuts, and require moderate tolerances. Cooling systems are more optimized. Many parts Jacky might design for consumer electronics could fall here.-

### Complex, High-Volume Molds (approx. $50,000 - $100,000+):These are built for demanding applications and high production volumes (millions of cycles). They often feature high cavitation (16, 32, or more cavities), complex actions (multiple sliders, lifters, unscrewing mechanisms), hot runner systems for efficiency, extremely tight tolerances, and are made from high-quality hardened tool steels or stainless steel (especially for medical). Surface finishes might be highly specialized (e.g., optical quality). Automation features might be included.

Cost Range Examples (Illustrative):Mold Type Typical Cavities Steel Type Complexity Estimated Cost Range Typical Lifespan (Cycles) Simple/Proto 1 Aluminum / P20 Low $2k – $10k < 10,000 Medium 2 – 8 P20 / H13 Medium $10k – $50k 50,000 – 500,000 Complex/HighVol 8 – 64+ H13 / S7 / SS High $50k – $100k+ 1,000,000+ Remember, these are general guidelines. A very small but incredibly complex part could require a mold costing more than a large, simple part. Always get a specific quote based on your design.

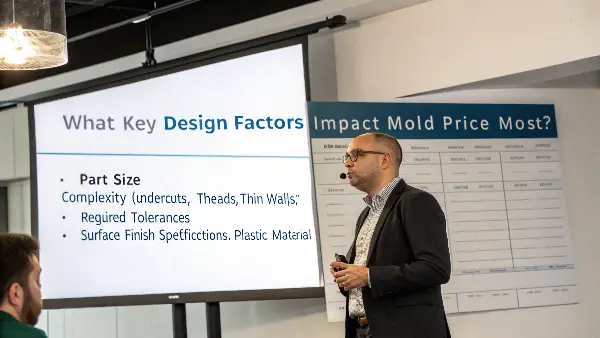

What Key Design Factors Impact Mold Price Most?

Want to design cost-effective parts for molding? Simple design changes can sometimes drastically affect mold cost without you realizing it. Let’s pinpoint key factors you control.

Part size, complexity (undercuts, threads, thin walls), required tolerances, surface finish specifications, and the plastic material chosen have the biggest impact on mold cost. Simpler designs generally mean less expensive molds.

Diving Deeper: How Your Design Choices Drive Cost

As a designer like Jacky knows, your decisions directly influence the complexity and cost of the mold. Here’s how:

### Part Size and Overall Geometry:Larger parts require larger molds, consuming more steel and requiring larger machines, increasing material and machining costs. Complex overall shapes, even without specific features, can require more intricate machining paths and potentially more complex mold actions (like core pulls). Deep ribs or bosses also add complexity.### Undercuts, Threads, and Side Actions:Features that prevent the part from being directly ejected (undercuts) require mechanisms like sliders, lifters, or collapsing cores. These add significant complexity to the mold design, build, and maintenance, directly increasing cost. Internal or external threads usually need unscrewing mechanisms or collapsible cores. Designing to minimize or eliminate these features is a key DFM principle for cost reduction.### Tolerances and Precision:Tighter tolerances require more precise (and slower) machining, potentially more expensive mold base materials for stability, more rigorous quality control during manufacturing, and potentially more complex mold designs to manage thermal expansion. Consider if every tolerance specified is truly necessary for function. Relaxing non-critical tolerances can save significant cost.### Surface Finish Requirements:A standard machine finish (like SPI C-1) is the least expensive. Textured finishes require an extra step (usually chemical etching or sandblasting). Polished finishes (like SPI A-2 or A-1 mirror polish) require extensive, skilled manual labor and add substantial cost and time. Specify only the finish required for function or aesthetics.-

### Material Selection Impact:Some plastics are abrasive (e.g., glass-filled nylon) and require molds made from harder, more expensive tool steels to resist wear. Some have high shrink rates requiring more complex mold design and testing. Corrosive materials (like PVC) might necessitate stainless steel molds.

Design Feature Cost Impact Summary:Design Factor Low Cost Example High Cost Example Why it Impacts Cost Size Small (< 50mm cube) Large (> 300mm cube) Material volume, machine size Complexity Simple block shape Multiple undercuts, threads, thin walls Mold actions (sliders/lifters), machining time, design effort Tolerances +/- 0.010" (0.25mm) +/- 0.001" (0.025mm) Precision machining, QC, potentially better steel Surface Finish SPI C-1 (Machined) SPI A-1 (Mirror Polish) Manual labor for polishing Material Choice Polypropylene (PP) Glass-Filled PEEK Mold steel hardness needed, processing difficulty Engaging with us early for DFM feedback can help identify cost drivers in your design and explore alternatives.

Conclusion

Understanding mold cost factors empowers better design and budgeting. At CavityMold, we provide transparent pricing based on these elements, ensuring you get the right mold at a fair price.

-

Understanding the factors that influence injection mold costs can help you budget effectively and avoid unexpected expenses. ↩

-

Exploring how part complexity impacts pricing can provide insights into optimizing your design for cost efficiency. ↩

-

Learning about mold steel types can help you make informed decisions that affect durability and cost of your molds. ↩