Struggling with intricate parts or tight tolerances? High-pressure injection molding might be your answer. Let’s explore how CavityMOLD masters these complex manufacturing challenges.

Yes, CavityMOLD’s high-pressure injection molding solutions excel at solving complex manufacturing challenges by ensuring complete cavity fill, precise replication of intricate details, and optimal part density. This tackles issues like short shots, weak weld lines, and dimensional inaccuracies in complex geometries. It’s how we Master Molding Right!

I’ve been in this game for a while now, and let me tell you, the designs that land on our desks are getting more and more complex. It’s a good thing, really – it means innovation is alive and well! But it also means we constantly have to be at the top of our game. Project managers like Alex, who are juggling deadlines and quality standards for sophisticated consumer electronics, can’t afford slip-ups. They need partners who can take a complex design and turn it into a perfect part, time after time. That’s where the nuances of injection molding, especially high-pressure techniques, really shine. So, let’s dig into how we at CavityMOLD tackle these tricky situations.

How Do You Solve Injection Molding Problems, Especially the Really Nasty Ones?

Hitting a wall with a persistent molding defect? It’s frustrating, costs time, and eats into profits. So, how do you crack these tough nuts effectively?

Solving injection molding problems involves a systematic approach: analyze the defect, check material properties, optimize process parameters (like temperature, pressure, speed), and if needed, refine mold design. It’s about identifying the root cause, not just treating symptoms.

You know, when a molding problem pops up, it can feel like a real punch to the gut. I remember this one time, we had a part with a really thin wall section next to a thick rib – a classic recipe for trouble. We were getting sink marks that just wouldn’t quit. The pressure was on, the client was waiting, and my team was pulling their hair out. So, what do we do at CavityMOLD? We don’t just randomly start twisting knobs on the machine. That’s a recipe for more headaches.

Our approach is all about methodical problem-solving. First, we clearly identify the defect. Is it a sink mark, a short shot, flash, warping, or something else? Then, we gather all the data. What are the current process parameters? How’s the material behaving? We lean heavily on tools like mold flow analysis before steel is even cut. This helps us predict potential problem areas – like that thin wall I mentioned – and design solutions right into the mold. For instance, we might adjust gate locations or optimize cooling channels based on these simulations.

Then, it’s about systematically tweaking the process parameters. For that pesky sink mark, we looked at packing pressure and time. We also checked melt temperature to ensure the material wasn’t too hot. Sometimes, it’s a balancing act. Maybe increasing packing pressure helps the sink, but then you risk flash. It’s this iterative process, guided by experience and data. We also have a deep understanding of wall thickness control, which is super critical for complex designs. Ensuring uniform thickness or managing transitions properly is key to avoiding many defects. It’s not just about throwing more pressure at it; it’s about intelligent application of pressure and process knowledge. This detailed, problem-solving approach, backed by our advanced design tools and expertise in optimizing parameters like temperature and injection speed, is how we turn complex challenges into successful parts. That’s how we help guys like Alex sleep at night!

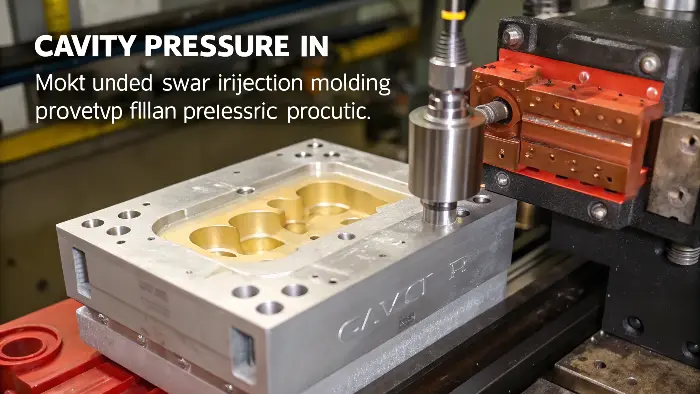

What’s the Big Deal with Cavity Pressure in Injection Molding, and Why Does It Matter So Much for Complex Parts?

Hearing about "cavity pressure" but not sure why it’s a hot topic? If it’s not right, your complex parts might fail. Understanding it is crucial.

Cavity pressure is the actual pressure of the molten plastic inside the mold cavity during injection and packing. It’s vital for ensuring the mold is fully packed, details are sharp, and part dimensions are consistent, especially for intricate designs.

Okay, let’s talk cavity pressure. If you’re new to molding, it might sound a bit technical, but trust me, it’s a cornerstone of making good parts, especially when you’re dealing with complex geometries or high-performance materials. Think of it like this: injection pressure is what the machine pushes with, but cavity pressure is what the plastic feels inside the mold. It’s the real deal.

Why is it so important? Well, for starters, if the cavity pressure isn’t high enough, the plastic might not reach every tiny nook and cranny of a complex mold. You could end up with short shots (incomplete parts) or poorly defined features. This is especially true for parts with thin walls or long flow paths. The plastic needs enough oomph to get everywhere before it starts to cool and solidify. I’ve seen designs with incredibly fine textures or tiny ribs – if your cavity pressure isn’t spot on, those details just won’t replicate properly.

At CavityMOLD, we pay very close attention to cavity pressure, particularly when we’re using our high-pressure injection molding solutions. Higher, controlled cavity pressure helps us overcome the flow resistance of complex paths. It also helps to pack out the part properly, which is essential for minimizing issues like sink marks and voids, and for achieving good dimensional stability and strength. We often use sensors inside the mold to monitor this pressure in real-time. This data is gold! It tells us exactly what’s happening during the fill and pack stages. We can then correlate this pressure profile with the final part quality. For a project manager like Alex, whose company makes precision components for consumer electronics, knowing that we have this level of control ensures that his complex parts will meet those tight specifications. It’s all about ensuring that molten material behaves exactly as we want it to, filling every detail of those complex geometry parts and ensuring proper wall thickness control. It’s a science!

Can Injection Molding Really Handle Those Crazy Complex Shapes and Tiny Details, Even Beyond Plastics Like With Ceramics and Metals?

Got a design that looks impossible to make? You might be surprised by what injection molding can achieve. But how far can it really go with complexity?

Yes, injection molding is exceptionally capable of producing parts with complex shapes and fine details due to the high pressures forcing material into intricate mold cavities. While CavityMOLD specializes in plastics, the core principles are adapted for metal (MIM) and ceramic (CIM) injection molding too.

It still amazes me sometimes what we can produce with injection molding. You see a CAD model on a screen, full of undercuts, ribs, living hinges, tiny bosses, intricate snap-fits – and you think, "Wow, how are we gonna make that in one piece?" But injection molding, especially when you have the expertise like we do at CavityMOLD, is fantastic for complex geometry parts. The magic lies in the mold itself – a precisely machined negative of your part – and the ability to force molten material into every crevice under high pressure.

This process allows for an incredible level of detail. Think about the texture on a car’s dashboard, the tiny gears in a printer, or the complex housing of a modern smartphone. Many of these are injection molded. The tooling might be complex, requiring slides, lifters, or even multi-shot capabilities, but the result is a net-shape part with features that would be incredibly difficult or expensive to achieve with other methods like machining from a solid block. We use advanced design and testing tools, like CAD software for designing the molds and mold flow analysis to simulate how the plastic will fill the cavity. This virtual testing is crucial. It helps us anticipate issues like air traps or weld lines in complex designs before we even cut steel for the mold. This proactive approach saves a ton of time and money, and ultimately, it’s how we can confidently take on those "crazy complex shapes."

Now, the question mentions ceramics and metals. Yes, Metal Injection Molding (MIM) and Ceramic Injection Molding (CIM) are very real and powerful technologies that adapt these principles for those materials. They use a feedstock of metal or ceramic powder mixed with a binder, inject it like plastic, and then sinter the part to remove the binder and fuse the powder. It’s super cool stuff for making small, complex metal or ceramic parts in high volumes. However, here at CavityMOLD, our core business and deep expertise lie in plastic injection molding. We live and breathe polymers! While the fundamental idea of forcing material into a mold is similar, the specifics of materials, temperatures, and post-processing are quite different. So, for those super intricate plastic parts, you bet, we’re your team!

If Injection Molding is So Great, Why Isn’t It Always the Go-To for Really BIG Products Then?

Injection molding seems super versatile, right? But if you’re thinking of making something huge, like a car bumper or a kayak, hold on… there are limits.

Injection molding isn’t always suitable for very large products due to extremely high mold costs, massive machine size requirements, long cooling times for thick sections, and potential material stresses. Other processes are often more economical for huge items.

This is a great question, and it really highlights that no single manufacturing process is perfect for everything. While injection molding is king for producing vast quantities of small to medium-sized parts with incredible complexity and precision, it starts to hit some practical and economic walls when you scale up to really large products.

Think about the mold itself. For a small, intricate part, the mold might be complex but still manageable in size and cost. Now imagine a mold for something like a large water tank or a playground slide. The sheer amount of tool steel required would be immense, and the machining time to create such a massive cavity would be astronomical. The cost of that mold alone could run into hundreds of thousands, or even millions, of dollars. That’s a huge upfront investment.

Then there’s the machine size. You’d need an injection molding machine with a massive clamping force to hold that giant mold together against the injection pressure, and a huge shot size to deliver enough molten plastic. These machines are enormous and incredibly expensive. For instance, I once visited a facility that made large automotive components, and their biggest press was the size of a small house!

Beyond cost and machinery, there are technical challenges. For very large, thick-walled parts, cooling times can become incredibly long. Plastic is a poor conductor of heat, so getting the core of a massive part to solidify properly without causing internal stresses, voids, or excessive warping is a serious engineering challenge. This dramatically increases cycle times, reducing the "high-volume" advantage of injection molding. Processes like rotational molding, thermoforming, or even structural foam molding are often better suited for these very large items because they can handle lower volumes more economically or are inherently better for large, hollow, or less complex shapes. So, while we at CavityMOLD excel at pushing the boundaries of complexity for parts that fit within the practical limits of injection molding, even we know when to say, "Perhaps another method is better for that particular giant!" It’s all about picking the right tool for the job, and we focus on mastering the art of complex, precise injection molding for parts where it truly shines.

Conclusion

CavityMOLD leverages high-pressure injection molding and deep expertise to conquer complex designs, ensuring quality and efficiency. We truly help you Master Molding Right, every single time.