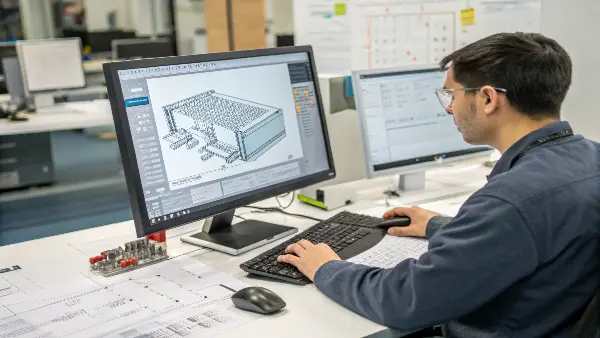

How Can You Optimize Draft Angles for Textured Surfaces to Prevent Scratches?

Have you ever designed a part with a beautiful textured finish, only to see it come out of the mold with ugly drag marks? This

Have you ever designed a part with a beautiful textured finish, only to see it come out of the mold with ugly drag marks? This

Are you tired of seeing perfectly good parts rejected because of a few surface scratches? These defects can halt production, inflate costs, and damage your

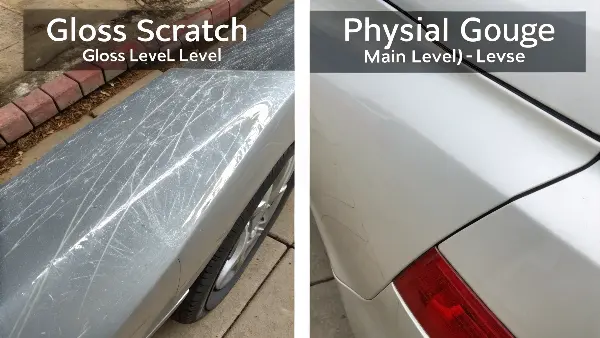

Struggling to get your plastic part manufactured correctly? You might have a great design, but if it ignores the material’s properties, you’re heading for costly

Struggling with post-production defects like sink marks and warpage? These issues waste time, increase costs, and delay your projects. Optimizing your part design from the

Designing strong plastic parts with features like ribs and bosses often leads to ugly sink marks on the surface. These cosmetic flaws can cause part

Are your plastic parts failing with unexpected weld lines or sink marks? You’ve followed the design rules, but production issues still cause costly delays and

Designing a complex plastic part can feel like navigating a maze. You followed all the basic rules, but the final product still gets stuck, warped,

Struggling to design plastic parts that are strong, lightweight, and cost-effective? Getting this balance wrong can lead to weak products, ugly sink marks, and wasted

Struggling to pick the right plastic for your part? Relying solely on mechanical properties from a datasheet can lead to costly manufacturing problems, compliance failures,

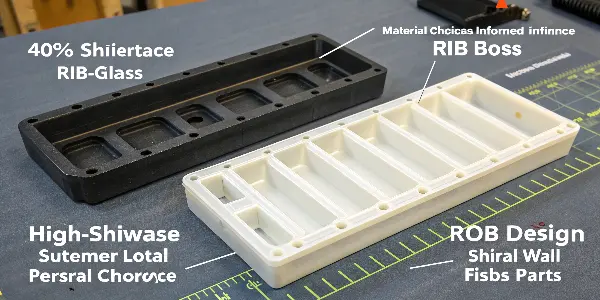

Are you struggling with parts that look strong but fail unexpectedly at a specific seam? This weakness, often found in fiber-reinforced plastics, can derail entire

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”