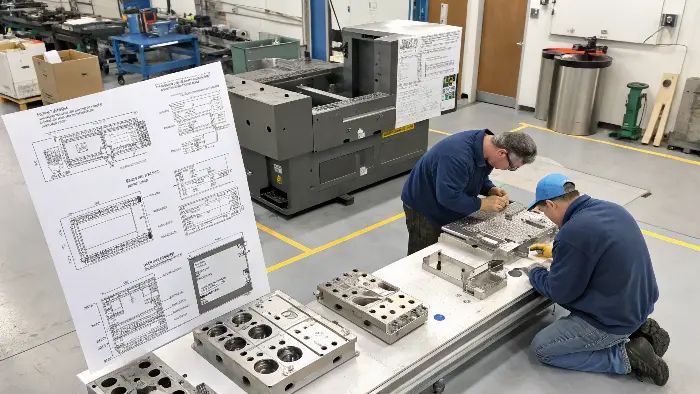

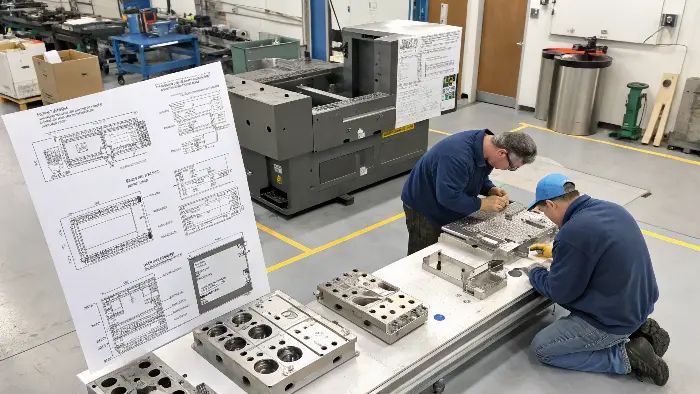

Ever Wonder How a Plastic Mold Goes From Design to a Production-Ready Tool?

Struggling to grasp the entire plastic mold making journey? It can seem super complex, risking project delays. This guide breaks it down, making it easy

Struggling to grasp the entire plastic mold making journey? It can seem super complex, risking project delays. This guide breaks it down, making it easy

Struggling with plastic mold choices? Picking the wrong one can sink your project fast. This guide demystifies mold types, ensuring you select perfectly every time.

Ever struggled with TPU overmolding, where parts peel apart? It’s frustrating, wastes cash, and tanks your product’s rep. We’ll show you how we achieve solid,

Feeling a bit lost with TPU injection molding? It can seem tricky, and wrong turns mean wasted money. This guide simplifies it, from picking materials

You’re facing a production halt because your latest batch of parts is full of flaws. The pressure is on to find the cause, but with

Understanding how to calculate injection molding tonnage is crucial for anyone involved in the plastic manufacturing industry. This process ensures that the right amount of

Designing a plastic part with undercuts or complex geometries can feel like a puzzle. You know the final shape you need, but getting it out

Struggling to get your thin-wall parts right? Warping, short shots, and cracks are probably driving you crazy and costing you a ton of money and

Frustrated with TPU defects? Tiny parameter tweaks can make a huge difference. Get it right for flawless parts! Fine-tuning TPU injection molding involves meticulous control

Figuring out what makes a plastic injection molding machine "good" can feel like a maze, right? You’re looking for reliability, precision, and something that fits

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

Send your drawings and detailed requirements via:

Email: jerry@cavitymold.com

Or fill out the contact form below:

We will contact you within one working day. Please pay attention to the email with the suffix “@cavitymold.com”