Choosing the right mold type feels like a high-stakes decision. You worry that picking the wrong one will blow your budget and delay production schedules. This uncertainty can be paralyzing, but making a clear, informed choice is crucial for your project’s success and profitability.

The best choice depends entirely on your production volume and budget. For high-volume, long-term production of identical parts, a multi-cavity mold is more cost-effective because it lowers the price per part. For smaller batches, prototyping, or very large and complex parts, a single-cavity mold offers lower upfront costs and greater design flexibility.

I’ve seen many project managers like you weigh these options. The decision isn’t just about the initial tool cost; it’s about the total cost of ownership and how the tool aligns with your business goals. It’s a critical step, and getting it right sets the foundation for a smooth production run. Let’s break down the details so you can feel confident in your decision.

What is a cavity in tooling?

You often hear engineers and suppliers talk about "cavities," but you might not be 100% clear on what it means. This small gap in knowledge can lead to miscommunication and costly assumptions down the line. Let’s clear it up so you can speak the language of mold making with confidence.

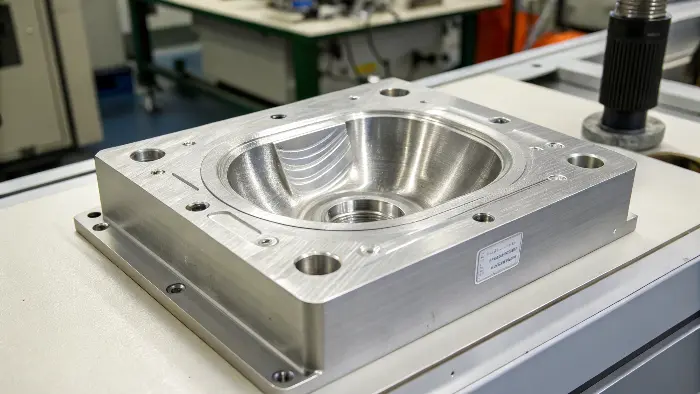

A cavity in tooling is the precisely machined hollow space inside a mold that gives a part its final shape. When molten material like plastic is injected, it fills this cavity, cools, and solidifies. Essentially, the cavity is the negative image of the product you want to create.

Think of a mold cavity like an ice cube tray. The tray itself is the mold, and each individual cube-shaped depression is a cavity. In industrial molding, this concept is the same, but the precision required is on another level. The cavity is typically formed by two halves of the mold coming together: the "cavity" side (usually the exterior or cosmetic side of the part) and the "core" side (the interior or non-cosmetic side).

The quality of the final product is directly tied to the quality of the cavity. This includes several key aspects:

Key Aspects of a Mold Cavity

| Aspect | Description | Impact on Final Part |

|---|---|---|

| Material | The type of steel used (e.g., P20, 718H, H13, S136). | Determines the mold’s lifespan, durability, and ability to hold fine details. Harder steels last longer but cost more. |

| Surface Finish | The texture of the cavity walls, from rough matte to a mirror polish. | Directly translates to the surface finish of the plastic part. A polished cavity creates a glossy part. |

| Dimensional Accuracy | How closely the cavity’s dimensions match the original CAD design. | Ensures every part produced is within the required tolerance and functions as intended. |

| Venting | Tiny channels that allow trapped air to escape as plastic fills the cavity. | Prevents defects like short shots (incomplete parts) or burn marks caused by compressed air. |

Understanding the cavity is the first step to understanding the entire mold. It’s the heart of the tool, where your design becomes a physical reality.

What is a single-cavity mold?

You have a new product, but you’re not sure if committing to a complex, expensive mold is the right first step. Investing too much too soon on a tool can be a huge financial risk, especially if the design isn’t finalized. Understanding the role of a single-cavity mold shows why it’s often the smartest and safest way to begin.

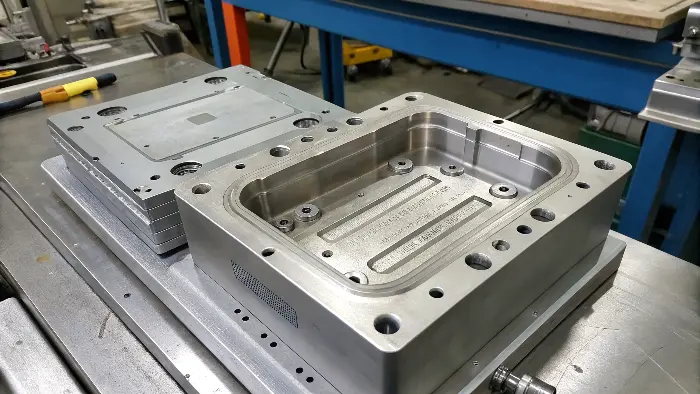

A single-cavity mold, also known as a single-impression mold, is a tool designed to produce only one finished part per machine cycle. It’s the ideal choice for low-volume production runs, prototyping, very large parts, or projects where you expect to make design changes.

I always recommend single-cavity molds in specific situations. For example, a client in Australia needed to develop a new casing for a handheld medical device. The design required rigorous testing and several iterations. We started with a single-cavity mold made from P20 steel. This allowed them to get functional prototypes quickly and affordably. After three rounds of modifications, they finalized the design. Only then did we discuss scaling up. Starting with a single cavity saved them from scrapping a much more expensive multi-cavity tool.

This approach is perfect for several scenarios:

- Prototyping and Market Testing: When you need to validate a design or test market interest, a single-cavity mold provides the lowest upfront investment. It’s faster to build and much easier to modify than a multi-cavity tool.

- Large Parts: For bulky items like automotive bumpers or large electronic housings, the sheer size of the part makes a single-cavity mold the only practical option. Fitting multiple large cavities into one mold base would be mechanically unfeasible and incredibly expensive.

- Complex Parts: If a part has intricate geometry, side actions, or complex lifters, designing it into a single-cavity mold is simpler. It allows the toolmaker to focus on perfecting one impression without the added complexity of balancing material flow across multiple cavities.

- Low-Volume Production: If your product has a niche market and you only plan to produce a few thousand units per year, a single-cavity mold is the most economical choice. The higher cost per part is easily offset by the massive savings on the initial tooling investment.

What is the difference between a single-cavity and a multi-cavity mold?

You need to scale up, but you’re caught between sticking with a single-cavity tool or investing in a multi-cavity one. Making the wrong call means you either can’t meet your production targets or you’ve spent a fortune on a tool you can’t fully utilize. A clear, direct comparison will make the best path forward obvious.

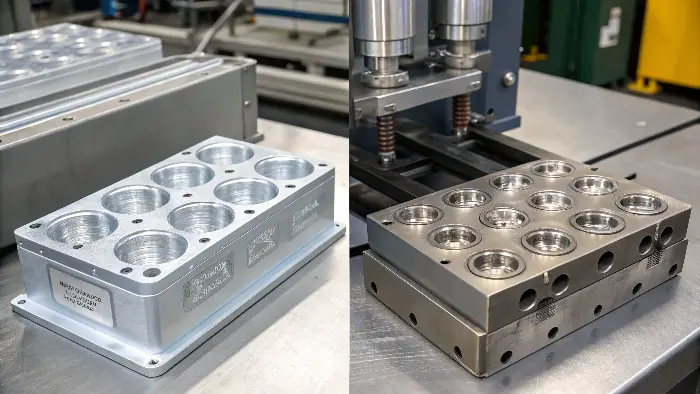

The primary difference is output. A single-cavity mold makes one part at a time, while a multi-cavity mold makes several identical parts simultaneously. This makes multi-cavity molds vastly more efficient for high-volume production, which dramatically lowers the cost per part but requires a much higher initial investment in the tool itself.

The choice between them is one of the most fundamental decisions in planning for mass production. It’s a classic trade-off between upfront capital expenditure and long-term operational efficiency. A multi-cavity mold multiplies your output without multiplying your labor or machine time by the same factor. For instance, a 4-cavity mold produces four parts in roughly the same cycle time as a single-cavity mold, instantly quartering the molding cost component of your part price.

However, this efficiency comes at a price. The mold is more complex to design, build, and maintain. Ensuring that all cavities fill evenly and produce identical parts (a process called "balancing") requires significant engineering expertise.

Let’s break down the comparison point by point:

Single-Cavity vs. Multi-Cavity Mold Comparison

| Feature | Single-Cavity Mold | Multi-Cavity Mold |

|---|---|---|

| Upfront Tooling Cost | Low | High (can be 3-4x or more) |

| Cost Per Part | High | Low |

| Production Output | Low (1 part per cycle) | High (2, 4, 8, or more parts per cycle) |

| Cycle Time | Slower (on a per-part basis) | Faster (on a per-part basis) |

| Tool Complexity | Simple | Complex (requires balanced runner systems) |

| Maintenance | Easier and cheaper | More complex and costly |

| Design Flexibility | High (easy and cheap to modify) | Low (difficult and expensive to modify) |

| Ideal Use Case | Prototyping, low-volume, large parts | High-volume mass production |

I worked with a project manager, Alex, who faced this exact choice. His company was launching a new line of reusable food containers. For the initial launch of 5,000 units, we built a single-cavity mold. It was perfect. But when a major retailer placed an order for 500,000 units, that single-cavity tool couldn’t keep up. We then built an 8-cavity hot runner mold. The tool was expensive, but it slashed the part price by over 60% and allowed them to meet the massive order on time.

How much does a multi-cavity mold cost?

You understand that a multi-cavity mold will boost your production efficiency, but the potential price tag is a major hurdle. Without a clear idea of the cost and the factors that drive it, your project can get stuck in the budgeting phase. Let’s demystify the pricing so you can plan with confidence.

A multi-cavity mold can range from $10,000 for a simple 2-cavity tool to well over $100,000 for a complex, high-cavitation hot runner mold. The final cost is determined by the number of cavities, part complexity, mold steel, required tolerances, and the type of runner system used.

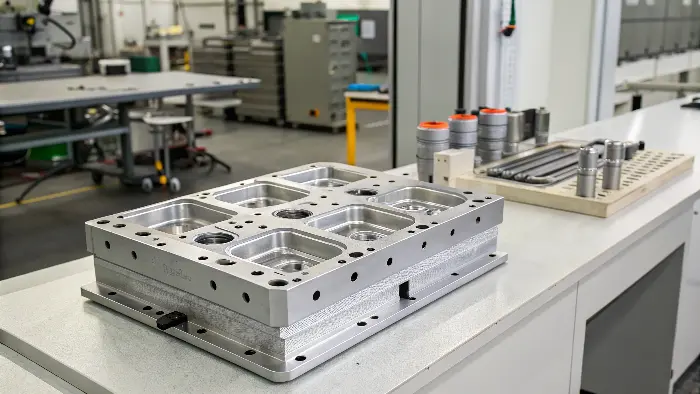

The cost of a multi-cavity mold isn’t linear. A 4-cavity mold is not simply twice the price of a 2-cavity mold. The complexity increases exponentially with each added cavity. The mold base is larger, more cooling channels are needed, and the runner system that delivers plastic to each cavity must be perfectly balanced to ensure every part is identical. Any imbalance can lead to inconsistent quality and high scrap rates.

Here are the main factors that influence the price:

- Number of Cavities: This is the biggest cost driver. More cavities mean more precision machining, more components, and a larger, more robust mold base to handle the higher injection pressures.

- Part Complexity: Features like undercuts, threads, or tight tolerances require mechanisms like sliders, lifters, or collapsible cores. Each of these adds significant cost and complexity to the tool’s design and construction.

- Mold Steel: The choice of steel impacts both cost and longevity.

- P20: A common, lower-cost pre-hardened steel suitable for up to 400,000 cycles.

- H13 or S136: Hardened tool steels that are more expensive but can last for 1 million+ cycles. They are necessary for high-volume production or when molding abrasive materials.

- Runner System:

- Cold Runner: Simpler and cheaper to build, but it creates a sprue of waste plastic with each shot, increasing material cost over time.

- Hot Runner: More expensive upfront, but it keeps the plastic molten all the way to the cavity gate. This eliminates waste, reduces cycle times, and often improves part quality, making it the standard for high-volume production.

Here’s a rough idea of how costs can scale for a relatively simple part:

| Mold Type | Number of Cavities | Runner Type | Estimated Cost Range | Best For |

|---|---|---|---|---|

| Simple Mold | 2 | Cold | $8,000 – $15,000 | 100k – 200k units |

| Standard Mold | 4 | Cold | $15,000 – $25,000 | 200k – 500k units |

| Production Mold | 8 | Hot | $40,000 – $70,000 | 500k – 1M+ units |

| High-Cavitation Mold | 16-32 | Hot | $70,000 – $150,000+ | Millions of units |

This investment is significant, but for the right project, the return in the form of a lower part price and higher output is undeniable.

Conclusion

Ultimately, the choice between a single-cavity and a multi-cavity mold comes down to your specific goals. Single-cavity molds offer flexibility and low initial cost for prototyping and small runs. Multi-cavity molds provide unmatched efficiency and a lower unit cost for high-volume mass production. Analyzing your project’s volume, budget, and long-term strategy will make the right answer clear.