Ever find yourself wondering if injection molding is always the king of manufacturing processes? It’s fantastic for high-volume, complex parts, no doubt. But sometimes, the tooling costs make your eyes water, or the lead times just don’t fit your project. You start thinking, "There has to be another way, right?" Well, you’re not alone in that thought.

While injection molding is a dominant force, "better" depends entirely on your specific needs. For small batches or rapid prototypes, 3D printing or vacuum casting might be superior. For continuous profiles, extrusion is ideal. And for certain materials or large, simpler shapes, compression molding or thermoforming could be more efficient.

It’s a common question I get, especially from folks looking at new projects or trying to optimize their production. At CavityMold, while we specialize in injection molds, we know it’s crucial to understand the whole manufacturing landscape. The truth is, injection molding is a superstar, but it doesn’t play every position on the field perfectly. Sometimes, another player is better suited for a specific task. Let’s explore some of these alternatives so you can make a more informed choice.

What is the best alternative to injection molding, really?

So, you’re looking for the "best" alternative to injection molding, but it feels like searching for a unicorn, doesn’t it? With so many options out there, from 3D printing to thermoforming, how do you pick the one that’s truly better for your specific project? It’s easy to get lost in the technical jargon and end up more confused than when you started.

The "best" alternative to injection molding isn’t a one-size-fits-all answer; it hinges on factors like production volume, part complexity, material requirements, desired surface finish, and budget. For instance, 3D printing excels for low-volume custom parts, while thermoforming is great for large, simpler shapes.

I’ve seen this play out so many times. A client comes to us, convinced they need an injection mold, but after we chat about their actual needs – say, only 50 prototype parts – we realize something like 3D printing or vacuum casting would save them a ton of time and money. It’s all about matching the process to the project. Let’s look at a few common scenarios and the alternatives that shine:

-

For Small Batches & Prototypes (Low Volume):

- 3D Printing (Additive Manufacturing): This is a game-changer for speed and complexity in low volumes. You can go directly from a CAD file to a physical part, often within hours or days. It’s perfect for testing designs, creating custom jigs, or even producing end-use parts if the volume is small enough. The material options are growing all the time too. I remember needing a really specific, complex bracket for a test rig – 3D printing had it in my hands the next day. No way injection molding could touch that speed for a one-off.

- Vacuum Casting (Urethane Casting): If you need a small batch (say, 10-100 parts) with properties closer to injection molded parts and a better surface finish than some 3D prints, vacuum casting is fantastic. You typically 3D print a master pattern, make a silicone mold from it, and then cast urethane resins. It’s more labor-intensive than direct 3D printing per part, but great for functional prototypes or small production runs. We’ve used this for early market testing units.

-

For Large, Simpler Parts or Speed in Development:

- Thermoforming (Vacuum Forming/Pressure Forming): This process involves heating a plastic sheet until it’s pliable, then forming it over or into a mold using vacuum or pressure. It’s often more cost-effective for large parts with relatively simple geometries, like trays, enclosures, or vehicle dashboards. Tooling is generally much cheaper and faster to make than injection molds. As my insights noted, manufacturers can use thermoforming to develop large products and parts, and it’s often an efficient and economical molding process, especially when development speed is key.

-

For Continuous Lengths of a Profile:

- Extrusion: We’ll dive deeper into this one next, but if you need long, continuous shapes with a consistent cross-section (like pipes, window frames, or seals), extrusion is the way to go, not injection molding.

The key takeaway here is that "best" is relative. You need to weigh your priorities: Is it speed to market for a prototype? Lowest cost per part at high volume? Specific material properties? Answering these questions will point you toward the most suitable alternative.

Is extrusion better than injection molding, or just different?

You hear about extrusion and injection molding, and sometimes they get mentioned in the same breath, which can be confusing. Is one inherently "better," or are they just different tools for different jobs? You might be wondering if you could use extrusion for your part and save some money or time, but you’re unsure if it’s even appropriate.

Extrusion is not inherently "better" than injection molding; they are designed for fundamentally different types of products. Extrusion excels at producing continuous linear shapes with a consistent cross-section, while injection molding is for creating discrete, often complex, three-dimensional parts.

Think of it like this: extrusion is like squeezing toothpaste out of a tube – you get a long, continuous shape defined by the opening. Injection molding is more like using a Jell-O mold – you fill a cavity to create a specific, individual shape. They really are apples and oranges, or maybe more like spaghetti and meatballs!

Let’s break it down:

-

Extrusion:

- Process: Plastic pellets are melted and forced through a die with a specific cross-sectional shape. The output is a continuous profile that is then cooled and cut to length.

- Products: Think pipes, tubing, window frames, door seals, plastic lumber, sheet stock, and films.

- Advantages: Excellent for high-volume production of parts with a uniform profile. Tooling (the die) is generally much simpler and less expensive than an injection mold. As my insights mentioned, for high-volume production of these types of parts, extrusion is faster and can offer a quicker return on investment.

- Limitations: Limited to 2D complexity (the cross-section). Not suitable for creating standalone, intricate 3D objects with varying wall thicknesses or complex features like bosses or ribs unless those are part of the continuous profile.

-

Injection Molding:

- Process: Melted plastic is injected under high pressure into a closed mold cavity that defines the shape of the part.

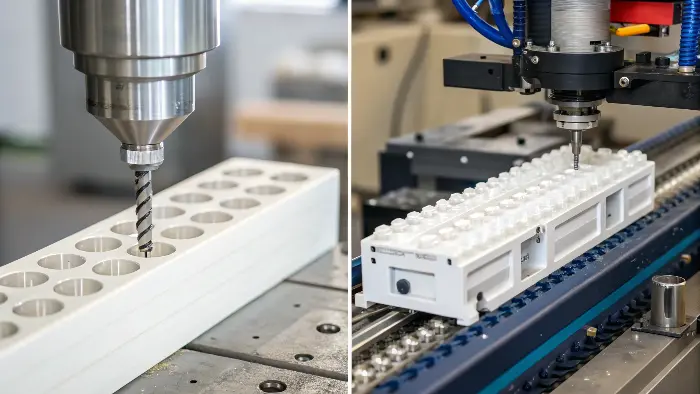

- Products: Almost anything you can imagine that’s a discrete plastic part – phone cases, car interior components, bottle caps, LEGO bricks, medical device housings.

- Advantages: Can produce highly complex 3D parts with intricate details, varying wall thicknesses, and tight tolerances. High production rates once the mold is made.

- Limitations: Tooling is expensive and has long lead times. Not suitable for continuous profiles.

I once had a client ask if we could make a 10-foot long, simple U-channel using injection molding. While technically possible with a massive, specialized machine and mold, it would have been astronomically expensive and inefficient. Extrusion was the obvious, far more cost-effective solution for that particular product. So, neither is "better" overall; they are "better" for specific applications. If your part is long and has a consistent profile, extrusion is your friend. If it’s a discrete, complex object, injection molding is likely the way to go.

Is compression or injection molding better for my parts?

When you’re looking at molding processes, compression molding often comes up, especially if you’re working with certain types of materials like thermosets or elastomers. You might be wondering if it could be a more cost-effective or suitable option than injection molding for your specific components. The worry is choosing a process that isn’t optimized for your material or part geometry.

Compression molding is often better for large, relatively simple, or bulky parts, particularly those made from thermosetting plastics or elastomers like rubber. Injection molding generally offers higher precision and is better for complex thermoplastic parts with intricate details and faster cycle times.

I’ve found that understanding the fundamental differences helps clear this up. Compression molding is one of the oldest molding techniques, and it’s still very relevant for certain applications. Think of it like making a waffle – you put the batter (the pre-form of material) into the hot waffle iron (the mold) and then close it, applying pressure.

Here’s a closer look:

-

Compression Molding:

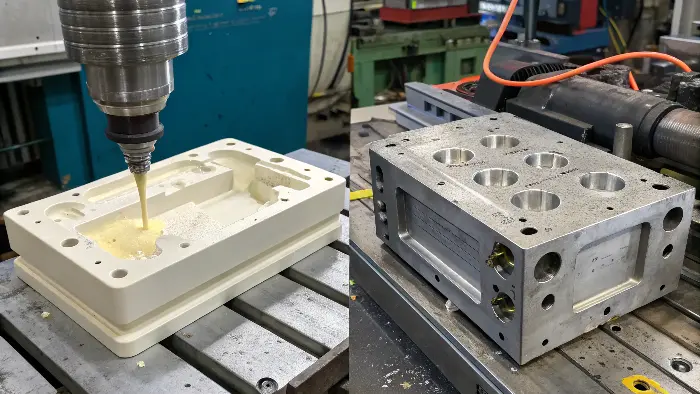

- Process: A pre-measured amount of molding material (often a pre-heated "charge" or "pre-form") is placed directly into the heated lower mold cavity. The top half of the mold is then closed, applying pressure (hence "compression") to force the material to fill the cavity and cure.

- Materials: Commonly used for thermosetting plastics (like phenolics, epoxies, melamines) which cure and harden permanently with heat, and elastomers (like rubber). My insights correctly point out that for certain materials, like rubber, compression molding can be a better choice.

- Products: Electrical components, dinnerware, automotive parts (especially rubber ones like gaskets or seals), large, relatively flat or bulky items.

- Advantages:

- Tooling can be simpler and less expensive than injection molds, especially for straightforward parts, which can reduce mold costs.

- Good for very large parts or parts with thick cross-sections.

- Minimal material waste (less runner and sprue scrap compared to some injection molding setups).

- Can handle high-viscosity materials well.

- Disadvantages:

- Cycle times are generally longer than injection molding because the material cures in the mold.

- Less suitable for highly intricate or complex parts with fine details or undercuts.

- Achieving very tight tolerances can be more challenging; precision might be sacrificed somewhat, as noted in my insights.

- More potential for flash if the charge isn’t perfectly measured or the mold isn’t perfectly sealed.

-

Injection Molding (for comparison):

- Process: Material is melted and injected into a closed mold.

- Materials: Primarily thermoplastics, though specialized thermoset injection molding exists.

- Advantages: High precision, complex geometries, fast cycle times, high automation potential.

I remember a project involving large, thick rubber vibration dampeners. Injection molding them would have been tricky due to the material and the cure time needed. Compression molding was the perfect fit – the tooling was more straightforward, and it handled the bulky rubber part beautifully. However, for a complex housing with lots of little snaps and ribs made from ABS, injection molding would be the undisputed champion. So, if your part is large, relatively simple, and made of a thermoset or rubber, compression molding is definitely worth considering.

What is the difference between RTM and injection molding, anyway?

You might hear about Resin Transfer Molding (RTM) and wonder how it stacks up against traditional injection molding. It sounds a bit similar – injecting material into a mold – but is it just another variation, or something completely different? It’s easy to get these terms mixed up if you’re not dealing with them regularly.

Resin Transfer Molding (RTM) is primarily used for producing high-strength, lightweight composite parts by injecting a liquid thermosetting resin into a mold cavity pre-filled with a fiber preform. Injection molding, conversely, typically injects molten thermoplastic material into an empty mold cavity to form solid parts.

These two processes, while both involving "molding" and "injection," are really in different leagues and serve very different purposes. It’s like comparing a Formula 1 car (RTM for high-performance composites) to a reliable family sedan (injection molding for everyday plastic parts). Both get you places, but they are engineered for vastly different performance characteristics and applications.

Let’s break down RTM:

- Resin Transfer Molding (RTM):

- Process:

- A dry fiber reinforcement (like carbon fiber, glass fiber, or aramid) is cut and shaped into a "preform." This preform is placed into a closed mold.

- A liquid thermosetting resin (like epoxy, vinyl ester, or polyester) is then injected under relatively low pressure into the mold. The resin flows through the fiber preform, saturating it.

- The resin cures (often with heat), forming a solid, fiber-reinforced composite part.

- Materials: Fiber reinforcements (carbon, glass, etc.) and thermosetting resins.

- Products: High-strength, lightweight structural components. Think aerospace parts, high-performance automotive components (like chassis elements or body panels), boat hulls, wind turbine blades.

- Advantages:

- Excellent strength-to-weight ratio.

- Can produce large, complex composite structures with good surface finish on both sides (closed mold).

- Good dimensional accuracy and repeatability for composites.

- Disadvantages:

- Cycle times are generally much longer than thermoplastic injection molding due to resin cure times.

- More complex process involving preform creation and handling.

- Materials (especially carbon fiber and aerospace-grade resins) can be expensive.

- Tooling can still be costly, though pressures are lower than injection molding.

- Process:

Key Differences from (Thermoplastic) Injection Molding:

| Feature | Resin Transfer Molding (RTM) | Thermoplastic Injection Molding |

|---|---|---|

| Material Injected | Liquid thermosetting resin | Molten thermoplastic polymer |

| Mold Contents | Fiber preform already in place | Initially empty cavity |

| Primary Output | Fiber-reinforced composite parts | Solid thermoplastic parts |

| Injection Pressure | Low to moderate | High |

| Cycle Time | Longer (due to resin cure) | Shorter (due to thermoplastic cooling) |

| Typical Parts | Structural, high-strength, lightweight components | Wide variety, from consumer goods to automotive |

I once visited a facility making components for racing yachts – the precision and strength they achieved with RTM for carbon fiber parts was just incredible. But it was a very different world from our day-to-day at CavityMold, where we’re focused on the precision and speed of injection molding for thermoplastics. So, RTM isn’t really an "alternative" in the sense of making the same kinds of parts as typical injection molding; it’s a specialized process for a different class of materials and performance requirements.

Conclusion

While injection molding is a powerhouse for many applications, it’s not always the "better" or only choice. Depending on your volume, part complexity, material, and budget, alternatives like 3D printing, vacuum casting, extrusion, thermoforming, or compression molding might be a superior fit. Understanding these options helps you, and us at CavityMold, truly Master Molding Right for every unique project.