Ever felt a bit lost when engineers start talking about molds? It’s a complex world, and not knowing the basics can make you feel out of your depth, especially when big projects are on the line. But understanding these core parts is key to smoother production and better products. This article breaks it all down for you.

The seven basic components of an injection mold are typically the molding parts (cavity and core), the runner system, the guiding mechanism, side parting and core-pulling mechanisms (if needed), the ejection system, the cooling/heating system, and the venting system. Knowing these helps you understand how a mold works and what makes a good design.

Alright, so you’re looking to get a handle on what actually makes up an injection mold. It’s not just a simple block of metal, that’s for sure! I remember when I first started, it felt like learning a whole new language. But stick with me, and we’ll unpack this. Understanding these bits and pieces is super important, especially if you’re like Alex, our project manager friend, who needs to make sure everything runs like clockwork. Let’s dive in and see what these components are all about.

What is the basic of injection molding, and how does it work?

Feeling overwhelmed by the technical jargon of injection molding? It’s easy to get bogged down in details and lose sight of the fundamental process. This can make it hard to grasp why certain mold components are so crucial. But understanding the basics is the first step to mastering the whole shebang.

At its core, injection molding involves melting plastic, injecting it under high pressure into a precisely machined mold cavity, allowing it to cool and solidify into the desired shape, and then ejecting the finished part. This cycle repeats to produce large volumes of identical parts efficiently.

So, let’s talk about the real basics of injection molding. Imagine you have a super-powered glue gun, but instead of glue, it’s molten plastic, and instead of just squeezing it out, it’s shot into a very specific, custom-made shape – that’s your mold.

First, tiny plastic pellets are fed into a hopper. Think of it like a funnel. These pellets then travel into a heated barrel where a big screw pushes them forward. As they move, they melt and mix, turning into a hot, gooey liquid. This part is the "injection unit" of the machine.

Then, the magic happens. This molten plastic is injected – bam! – under really high pressure into the mold. The mold itself is clamped shut super tight by the "clamping unit" of the machine. Inside the mold, there’s a cavity, which is the exact negative shape of the part you want to make. The plastic fills this cavity.

Next, the mold has cooling channels, and water usually runs through them to cool the plastic down so it solidifies. Once it’s hard, the mold opens up, and the part is pushed out, usually by ejector pins. And then the whole cycle starts again. It’s a pretty neat process, and it’s how we get so many of the plastic things we use every day. For someone like Alex, understanding this cycle is vital for planning production times and troubleshooting. It’s the foundation for everything else we’ll discuss.

What are the components of an injection molding press, and how do they interact with the mold?

Ever wondered what makes the actual injection molding machine tick, beyond just the mold itself? It’s easy to focus on the mold, but the press is the powerhouse that makes it all happen. Not knowing its parts can leave a gap in your understanding of the whole system.

An injection molding press primarily consists of three main units: the injection unit (melts and injects plastic), the clamping unit (holds the mold closed and opens it), and the control unit (manages the entire process). These units work in concert with the mold to produce parts.

Okay, so we’ve talked about the mold, but the mold doesn’t work in a vacuum, right? It needs a machine to operate it, and that’s the injection molding press, or machine. Think of the mold as the custom cassette, and the press as the cassette player. I always find it helpful to break things down.

There are really three main parts to the press:

-

The Injection Unit: This is the part that handles the plastic. It takes the raw plastic pellets, melts them down in a heated barrel with a screw, and then injects this molten plastic into the mold. It’s all about precision here – the right temperature, the right pressure, the right amount of plastic. If this isn’t spot on, you get all sorts of problems with the final part. I remember one project where the injection pressure was just a tiny bit off, and we ended up with parts that weren’t fully formed – a real headache!

-

The Clamping Unit: This is the muscle of the machine. Its job is to hold the two halves of the mold tightly together while the plastic is being injected. And I mean tightly. The pressure from the injection is immense, so this unit has to be strong enough to resist it and keep the mold sealed. After the plastic cools, the clamping unit opens the mold so the part can be ejected. It also houses the mechanism for ejecting the part.

-

The Control Unit: This is the brain. It’s usually a sophisticated computer system that controls and monitors everything – temperatures, pressures, speeds, timings for injection, cooling, opening, closing, ejection. Modern machines have incredibly precise controls, which is great for consistency. For Alex, knowing that we at CavityMold design molds to work seamlessly with these press controls is a big plus. It ensures our molds perform reliably.

These three parts of the press work together in a very coordinated dance with the mold to produce parts, cycle after cycle. It’s a pretty impressive piece of engineering when you see it in action.

What are the main elements of a mold, the heart of injection molding?

Struggling to picture what’s inside an injection mold? It’s more than just a shaped cavity; it’s a complex assembly of interacting parts. Without knowing these elements, it’s tough to appreciate mold design or troubleshoot issues. Let’s open it up.

The main elements of an injection mold include molding parts (cavity & core), a runner system, a guiding mechanism, an ejection system, a cooling/heating system, a venting system, and sometimes side-action or core-pulling mechanisms. Each plays a vital role in producing a quality part.

Now, let’s get to the real star of the show when we talk about making plastic parts: the mold itself. I’ve spent years working with these, and honestly, the ingenuity that goes into a well-designed mold still impresses me. It’s not just a chunk of steel; it’s a precision instrument. When we at CavityMold talk about "Master Molding Right," this is where it all comes together. So, what are these key elements? I like to think of them as the seven essential systems.

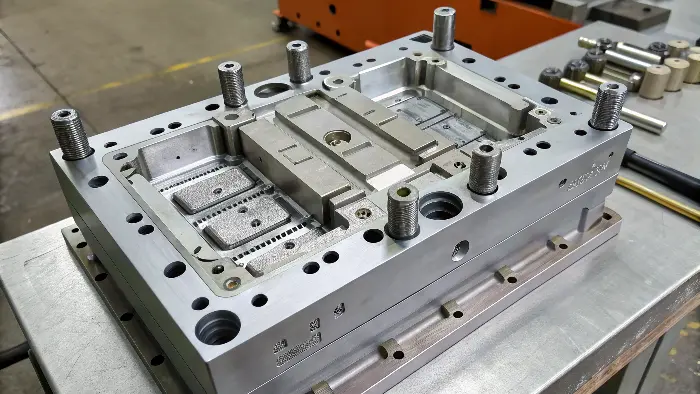

1. Molding Parts (Cavity and Core) – The Shapers?

These are the absolute heart of the mold. The cavity is the concave part, usually in the fixed half of the mold, that forms the external shape of your plastic product. The core is the convex part, often in the moving half, that forms the internal shape. When the mold closes, the cavity and core come together to create the void that the molten plastic will fill. The precision here is paramount. I mean, we’re talking tolerances down to fractions of a millimeter. Any imperfection in the cavity or core will be directly transferred to every single part produced. This is where a lot of the upfront cost in mold making goes – getting these surfaces perfectly machined and polished. For a project manager like Alex, the quality of these molding parts directly impacts the final product’s look, feel, and function.

2. Runner System – The Delivery Network?

Okay, so you have the cavity and core. How does the molten plastic get there? That’s the job of the runner system. It’s like a network of channels that guides the plastic from the nozzle of the injection molding machine to the actual part cavity. It typically includes:

- Sprue: The main channel where plastic first enters the mold from the machine’s nozzle.

- Runners: Smaller channels that branch off from the sprue to lead plastic towards the cavities (if it’s a multi-cavity mold).

- Gates: The very specific point where the plastic enters the cavity. The design of the gate is super critical – its size, shape, and location affect how the cavity fills, the part’s appearance, and how easily it can be removed from the runner later. There are tons of different gate types, each for different needs. Getting this system right means less wasted material and better part quality.

3. Guiding Mechanism – Keeping it Aligned?

With all that pressure and movement, you need to make sure the two halves of the mold align perfectly every single time they close. That’s where the guiding mechanism comes in. It usually consists of guide pins (strong steel pins on one mold half) and guide bushings (hardened steel sleeves on the other half). The pins slide into the bushings before the cavity and core fully engage, ensuring precise alignment. Without this, you’d get misaligned parts, or worse, damage to the expensive cavity and core. It’s a simple concept, but absolutely vital for the longevity and accuracy of the mold. Think of it like the guide rails on a drawer – they make sure it closes smoothly and correctly every time.

4. Side Parting and Core-Pulling Mechanism – For Complex Shapes?

What if your part has undercuts, holes on the side, or features that aren’t in the direct line of mold opening? You can’t just pull the part out then! This is where side parting and core-pulling mechanisms come into play. These are often called slides or lifters. They are moving parts within the mold that create those complex features and then retract before the main mold opens or during the ejection phase, allowing the part to be removed. These mechanisms add complexity and cost to a mold, but they are essential for producing intricate designs. I remember a particularly tricky part for a consumer electronics device Alex was managing; it had several side clips. The core-pulling system had to be perfectly timed. It’s like a little ballet of moving parts inside the mold.

5. Ejection System – Getting the Part Out?

Once the plastic has cooled and solidified, you need to get the part out of the mold. That’s the job of the ejection system. The most common components are ejector pins, which are round pins that push against the part to pop it out of the cavity. There can also be ejector sleeves (for pushing around a core pin) or stripper plates (for ejecting parts with thin walls). The placement and size of these ejector elements are important to push the part out evenly without damaging or deforming it. Sometimes you can see little circular marks on plastic parts – those are often from the ejector pins. For Alex, a well-designed ejection system means faster cycle times and fewer rejected parts.

6. Cooling and Heating System – Temperature Control is Key?

Controlling the temperature of the mold is crucial. The cooling system, usually a series of channels drilled through the mold plates through which water or oil circulates, removes heat from the molten plastic, allowing it to solidify quickly and consistently. The efficiency of the cooling system directly impacts the cycle time – the faster you can cool the part, the faster you can make more parts. Sometimes, certain parts of the mold might need to be heated (using cartridge heaters, for example) to ensure proper plastic flow or to achieve specific surface finishes. It’s a delicate balance. Uneven cooling can lead to warped parts or internal stresses. We at CavityMold pay a lot of attention to designing efficient cooling systems because it saves our clients time and money in production.

7. Venting System – Letting Air Escape?

When molten plastic rushes into the mold cavity, it displaces the air that’s already in there. If that air can’t escape, it gets trapped and compressed, leading to problems like incomplete filling (short shots), burn marks, or bubbles in the part. The venting system provides tiny channels or gaps, usually at the parting line or near ejector pins, that allow this trapped air (and any gases from the plastic itself) to escape while being too small for the molten plastic to flow out. It sounds minor, but proper venting is absolutely critical for high-quality parts. It’s one of those "unseen heroes" of the mold. I’ve seen projects struggle simply because the venting wasn’t adequate – a small detail with big consequences!

Understanding these seven elements really gives you a good picture of what goes into an injection mold. Each one has to work perfectly with the others. It’s why mold making is such a specialized skill!

Conclusion

So, there you have it – the essential components of injection molding, from the press to the intricate parts of the mold itself. Knowing these basics helps you understand the process, communicate better with manufacturers like us at CavityMold, and appreciate the engineering behind everyday plastic items. It’s all about "Master Molding Right."