Struggling with mounting plastic scrap1 and rising material costs in your molding facility? Letting valuable runner and sprue material go to waste hurts your bottom line and environmental goals.

A closed-loop system internally collects, regrinds, and reuses compatible plastic scrap (like runners, sprues, rejects) directly back into your production process, often for the same parts.

Implementing this isn’t just about being green; it’s smart business. As someone who helps companies like Jacky’s optimize their molding processes, I’ve seen firsthand how effective internal recycling2 can be. Let’s explore how you can set one up.

What defines a closed-loop recycling system in injection molding?

Confused about what "closed-loop" really means in your factory setting? The term gets used broadly, but for molders, it has a specific, practical application that impacts operations.

In injection molding, a closed-loop system specifically refers to reusing your internal production scrap (runners, sprues, non-conforming parts) by regrinding it and mixing it back into the virgin material feed within the same facility, often for the same product line.

Think of it as immediate, on-site recycling. Unlike sending scrap out for external reprocessing (open-loop), this keeps the material flow contained and under your direct control. It’s about maximizing resource efficiency right where the parts are made. Let’s dive deeper into what this entails.

Defining the "Loop" in Your Operation

Understanding the boundaries and characteristics of a true closed-loop system within an injection molding context is key to successful implementation.

- Source of Material: The primary input for the loop is predictable, clean scrap generated directly from your own production process. This typically includes:

- Runners and Sprues: Material left in the channels delivering plastic to the mold cavities. Hot runner systems minimize this, but cold runners are common sources.

- Rejected Parts: Parts that fail quality control checks but are made from uncontaminated, known material.

- Purgings: Material used to clean out the machine barrel during color or material changes (use requires careful consideration).

- Processing: The scrap is processed on-site. This usually involves granulation – grinding the plastic down into small, consistently sized flakes or pellets (regrind) that can be mixed with virgin resin. Drying may also be necessary depending on the material type.

- Re-integration: The regrind is typically blended with virgin material at a predetermined ratio (e.g., 10-30% regrind) and fed back into the same injection molding process it came from, or a compatible process within the facility.

- Contrast with Open-Loop: This differs significantly from open-loop recycling, where scrap might be collected, sent to an external recycler, potentially mixed with other plastics, and reprocessed into different, often lower-grade products. Closed-loop aims for higher value retention.

- Key Requirement: Maintaining material integrity and traceability is crucial. Strict controls are needed to prevent contamination and ensure the regrind doesn’t negatively impact final part quality or performance.

Why should my molding operation consider a closed-loop system?

Hesitant about the upfront investment for granulators and handling systems? Focusing only on the cost overlooks the significant financial and environmental upsides these systems offer.

Implementing a closed-loop system3 reduces virgin material purchasing costs, lowers waste disposal fees, enhances sustainability credentials, and can improve supply chain resilience by lessening dependence on external virgin resin supplies.

The economic argument alone is compelling. Every kilogram of regrind4 used is a kilogram of virgin material you don’t have to buy. When I work with clients, calculating this potential saving is often the first step. But the benefits extend beyond just the raw material costs.

Unpacking the Advantages

The decision to implement a closed-loop system is often driven by a combination of economic, environmental, and operational benefits.

- Direct Cost Savings:

- Reduced Material Purchases: This is usually the biggest driver. Virgin resin prices fluctuate, but using internally generated regrind directly offsets these costs. If you generate 10% scrap as runners and successfully reuse it, that’s potentially a near 10% reduction in virgin material needed for those jobs.

- Lower Waste Disposal Costs: Scrap plastic often incurs disposal fees (landfill, hauling). Recycling it internally eliminates or significantly reduces this expense.

- Environmental Sustainability:

- Resource Conservation: Reduces the demand for fossil fuel-based virgin plastics, conserving natural resources.

- Lower Carbon Footprint: Manufacturing virgin plastic is energy-intensive. Using regrind generally requires less energy than producing new resin, contributing to lower overall emissions associated with your product.

- Waste Reduction: Directly diverts plastic waste from landfills or incineration.

- Operational and Market Benefits:

- Supply Chain Resilience: Reduces reliance on potentially volatile virgin resin markets and supply chains. You have a partial source of material right in your facility.

- Improved Brand Image: Demonstrates commitment to sustainability, which can be attractive to customers (especially B2B clients like Jacky’s company) and stakeholders. Meets increasing demands for greener manufacturing practices.

- Potential Quality Control: Keeping the loop closed means you have better control and knowledge of the material history compared to using externally sourced recycled content.

While setting up the system requires investment, the ongoing savings and benefits often provide a strong return on investment over time.What are the key steps to establish an effective closed-loop system?

Ready to start recycling internally but unsure where to begin? Jumping in without proper planning can lead to contaminated material, damaged equipment, or poor part quality.

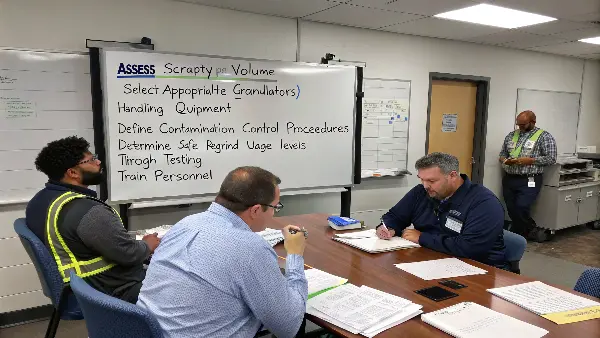

Establish a system by first assessing scrap type/volume, selecting appropriate granulators/handling equipment, defining strict contamination control procedures, determining safe regrind usage levels through testing, and training personnel.

Setting up a reliable system takes careful planning. I always advise starting with a thorough assessment. You need to know exactly what scrap you’re generating and how to handle it properly before you even think about buying a granulator. Let’s break down the typical implementation process.

Implementation Roadmap

Successfully establishing a closed-loop system involves several critical stages:

- Scrap Stream Assessment:

- Identify Sources: Map out where scrap is generated (which machines, which jobs).

- Quantify Volume: Measure the amount of scrap produced per material type. This helps size equipment correctly.

- Characterize Material: Confirm the exact type and grade of plastic for each scrap source. Absolutely crucial for preventing accidental mixing of incompatible materials.

- Assess Contamination Risk: Identify potential sources of contamination (dirt, oil, metal fragments, accidental mixing of different plastics).

- Equipment Selection:

- Granulators: Choose the right size and type (beside-the-press vs. central). Consider blade types, screen sizes (for consistent particle size), and soundproofing.

- Handling Equipment: Conveyors, loaders, potential dryers (for hygroscopic materials like Nylon or ABS), blenders for mixing regrind with virgin.

- Storage: Dedicated, clearly labeled bins or silos for different types of scrap and regrind to prevent mix-ups.

- Develop Procedures & Protocols:

- Handling & Segregation: Strict rules for collecting, transporting, and storing scrap to avoid contamination. Color-coding bins can help.

- Granulation Process: Define operating procedures for the granulator, including cleaning between materials.

- Labeling: Clear labels for all scrap and regrind containers indicating material type.

- Testing and Validation:

- Determine Max Regrind Percentage: Start with low percentages (e.g., 10%) and conduct rigorous testing on molded parts (dimensional stability, mechanical properties, appearance) to determine the maximum allowable level that doesn’t compromise quality. This varies greatly by material and application requirements.

- Quality Control (QC): Implement QC checks for the regrind itself (e.g., bulk density, visual inspection) and for final parts made with regrind.

- Training:

- Educate machine operators, material handlers, and QC personnel on the procedures, the importance of segregation, and potential quality issues.

This systematic approach minimizes risks and maximizes the chances of a successful, sustainable closed-loop system.What common challenges need addressing for successful closed-loop recycling?

Worried about hidden problems ruining your closed-loop efforts? Material degradation, contamination, and process inconsistencies can undermine the benefits if not actively managed.

- Educate machine operators, material handlers, and QC personnel on the procedures, the importance of segregation, and potential quality issues.

Key challenges include potential material degradation from repeated heat cycles, risk of contamination, maintaining consistent regrind quality, adjusting process parameters, and accurately tracking costs versus savings.

While the benefits are clear, it’s not always plug-and-play. I’ve seen operations struggle when they underestimate these challenges. For instance, simply adding regrind without adjusting molding parameters can lead to unexpected part defects. Awareness is the first step to prevention.

Navigating Potential Pitfalls

Implementing a closed-loop system requires vigilance to overcome inherent challenges:

- Material Degradation: Each time plastic is heated and processed, its molecular structure can degrade slightly (chain scission). This "heat history" can reduce mechanical properties (e.g., impact strength, tensile strength) and affect appearance (e.g., yellowing). Limiting the percentage of regrind and avoiding excessive processing temperatures helps mitigate this. Some materials tolerate reprocessing better than others.

- Contamination Control: This is arguably the biggest operational challenge. Contamination can come from:

- Foreign Objects: Dirt, dust, metal particles (from granulator wear), paper labels.

- Cross-Material Contamination: Accidentally mixing different plastic types (e.g., ABS regrind getting into a PP stream) can be catastrophic for part quality. Even different grades or colors of the same plastic can cause issues if not managed. Requires meticulous housekeeping and clear procedures.

- Regrind Quality Consistency: Variations in regrind particle size and shape distribution, or the presence of excessive dust (fines), can affect material flow in the molding machine and lead to processing inconsistencies or defects. Proper granulator maintenance (sharp blades, correct screen size) is vital.

- Process Adjustments: Regrind material may behave differently than 100% virgin resin (e.g., different melt flow rate, moisture content). Injection molding parameters (temperature, pressure, injection speed, cooling time) often need to be adjusted and re-validated when incorporating regrind.

- Tracking and Economics: Accurately calculating the true net savings requires tracking not just virgin material offset, but also the costs of equipment amortization, energy for granulation/drying, maintenance, additional labor, and QC efforts.

- Suitability Limitations: Not all applications are suitable for regrind, especially those with extremely tight tolerances, critical safety requirements, or specific optical properties where even minor degradation is unacceptable. Regulatory constraints (e.g., for food contact or medical applications) may also limit or prohibit regrind use.

Addressing these challenges proactively through robust processes and quality control is essential for long-term success.Conclusion

Implementing a closed-loop system offers significant cost savings and environmental benefits for injection molders. Success hinges on careful planning, contamination control, quality testing, and addressing potential material degradation.

-

Learning about plastic scrap management can enhance your production efficiency and reduce waste significantly. ↩

-

Exploring internal recycling methods can lead to cost savings and better resource management in your molding operations. ↩

-

Exploring this resource will provide insights into how closed-loop systems can enhance sustainability and reduce costs. ↩

-

Discover how using regrind can significantly cut costs and improve efficiency in production processes. ↩