Struggling with inconsistent part quality? Defects like warping and poor surface finish can ruin a production run and drive up costs. These issues often trace back to one critical factor: incorrect mold temperature. Getting it wrong costs you time, material, and money, but getting it right is the key to unlocking consistent, high-quality parts.

Mold temperature setting analysis is the process of determining and controlling the ideal temperature of the mold surface during injection molding. This critical analysis directly impacts the plastic’s cooling rate, affecting the final part’s properties, including its strength, surface finish, and dimensional stability. Proper analysis ensures high-quality parts and efficient production cycles by minimizing defects and maximizing repeatability.

Getting the temperature right is a game-changer. I’ve seen it make the difference between a perfect part and a pile of scrap. But this is just the beginning. To truly master your molding process, you need to understand the specifics of the entire setup. Let’s dive deeper into what these settings look like in practice and how you can control them effectively to achieve predictable, high-quality results every time.

What is the setting for injection molding?

Setting up an injection molding machine can feel like navigating a complex control panel with dozens of variables. A single wrong setting in pressure, speed, or time can lead to failed parts, material waste, and frustrating production delays. The secret is to focus on a few core settings that provide a solid foundation for any successful injection molding project.

The primary settings for injection molding include melt temperature, injection pressure, injection speed, holding pressure, and cooling time. These parameters work together to ensure the mold cavity is filled correctly and the part solidifies properly. Each setting must be carefully calibrated based on the plastic material, part design, and mold complexity to achieve optimal results and consistent quality.

When a new project manager like Alex comes to us, one of the first things we discuss is the importance of a holistic process window. It’s not just about mold temperature; it’s about how all the settings work together.

Core Injection Molding Parameters

Think of these settings as the essential ingredients in a recipe. If one is off, the final product suffers.

- Melt Temperature: This is the temperature of the plastic as it’s injected into the mold. Too low, and the plastic won’t flow properly, causing short shots. Too high, and you risk degrading the material, leading to brittle parts.

- Injection Pressure & Speed: This is the force and rate at which the melted plastic is pushed into the mold cavity. It needs to be fast and powerful enough to fill the entire mold before the plastic starts to cool and solidify.

- Holding Pressure & Time: After the mold is filled, we apply a holding pressure to pack more material in and compensate for shrinkage as the plastic cools. The time must be long enough for the gate (the entry point into the part cavity) to freeze solid.

- Cooling Time: This is the amount of time the part stays in the closed mold to solidify enough to be ejected without deforming. It’s often the longest part of the cycle, so optimizing it is key to efficiency.

The Interplay of Settings

No setting exists in a vacuum. Changing one will almost always require you to adjust another. For example, if you increase the melt temperature, the plastic becomes less viscous and flows more easily. This might allow you to reduce the injection pressure. However, a hotter part will require a longer cooling time to become stable. I remember a project where a client was getting sink marks on a thick-walled part. We didn’t just increase the holding pressure; we also slightly lowered the mold temperature to help the outer surface set faster while the holding pressure packed out the core.

| Setting Adjustment | Potential Positive Effect | Potential Negative Effect |

|---|---|---|

| Increase Melt Temp | Better flow, improved weld lines | Material degradation, longer cycle time |

| Increase Injection Speed | Fills thin sections, reduces freeze-off | Flash, high shear stress on material |

| Increase Holding Pressure | Reduces sink marks, better packing | Flash, overpacking, high internal stress |

| Decrease Cooling Time | Faster cycle time, higher output | Warpage, sink marks, part deformation |

What is the typical temperature for injection mold?

You know mold temperature is important, but you’re unsure where to even start with a new material. Guessing the temperature can lead to everything from brittle parts to a terrible surface finish, wasting valuable material and time. Knowing the typical temperature ranges for common plastics gives you a reliable starting point for every new project, saving you from costly trial and error.

Typical injection mold temperatures vary widely depending on the plastic material. For amorphous plastics like ABS, temperatures range from 40°C to 80°C (104°F to 176°F). For semi-crystalline plastics like Polypropylene (PP), it’s usually 30°C to 70°C (86°F to 158°F). High-performance materials like PEEK require much higher temperatures, often exceeding 150°C (302°F).

The first document I always ask for is the material supplier’s technical datasheet. It’s the bible for processing parameters. But understanding why those ranges exist is what separates a good molder from a great one. The key lies in the material’s molecular structure.

Temperature Ranges for Common Plastics

Plastics fall into two main families: amorphous and semi-crystalline. Their different behaviors during cooling dictate the required mold temperature. Here’s a quick reference guide we often share with our clients.

| Plastic Type | Material Name | Typical Mold Temp (°C) | Typical Mold Temp (°F) |

|---|---|---|---|

| Amorphous | ABS (Acrylonitrile Butadiene Styrene) | 40 – 80 °C | 104 – 176 °F |

| Amorphous | PC (Polycarbonate) | 80 – 120 °C | 176 – 248 °F |

| Amorphous | PS (Polystyrene) | 30 – 65 °C | 86 – 149 °F |

| Semi-Crystalline | PP (Polypropylene) | 30 – 70 °C | 86 – 158 °F |

| Semi-Crystalline | PA66 (Nylon 66) | 70 – 120 °C | 158 – 248 °F |

| Semi-Crystalline | POM (Acetal) | 80 – 105 °C | 176 – 221 °F |

| Semi-Crystalline | PEEK (Polyether Ether Ketone) | 150 – 200 °C | 302 – 392 °F |

Why Do Temperatures Vary So Much?

The difference comes down to how the polymer chains arrange themselves as they cool.

- Amorphous Plastics (like ABS, PC): Think of their molecular structure like a plate of cooked spaghetti. The chains are tangled randomly. They soften over a wide temperature range and don’t have a sharp melting point. This makes them a bit more forgiving. A hotter mold generally improves surface finish and flow but isn’t strictly necessary for the material to achieve its core properties.

- Semi-Crystalline Plastics (like PP, PA66): These materials are different. As they cool, parts of their molecular chains fold up into organized, crystalline structures. Think of some of the spaghetti strands aligning neatly. This crystallization process is what gives them their strength and chemical resistance. It requires a specific amount of energy and time, which is controlled by the mold temperature. If the mold is too cold, the crystals don’t form properly, and the part can be brittle and dimensionally unstable. A hotter mold is essential to control the rate of crystallization and reduce internal stresses.

How to determine mold temperature?

You have the recommended temperature range from the datasheet, but how do you pinpoint the exact number for your specific part? Choosing a temperature at the wrong end of the recommended range can still cause subtle defects like warpage or sink marks that only show up later. A systematic approach, combining data, simulation, and practical testing, is the professional way to determine the optimal mold temperature.

To determine the optimal mold temperature, start with the material supplier’s datasheet. Then, use mold flow analysis software to simulate the filling and cooling process, which helps predict potential issues. Finally, conduct practical trials on the molding machine, starting in the middle of the recommended range and adjusting based on part quality inspection, checking for defects like warpage, sink marks, and surface finish.

Finding the "sweet spot" for mold temperature isn’t guesswork; it’s a methodical process. When we work with a project manager like Alex, we guide them through a process that ensures predictable and repeatable results, minimizing risk before production even begins.

A Step-by-Step Guide to Finding the Sweet Spot

Here is the process we follow at CavityMold to zero in on the perfect temperature for a new tool.

-

Consult the Datasheet: This is always step one. It’s our non-negotiable starting point. The material manufacturer has done extensive testing and provides a safe and effective processing window for melt temperature and mold temperature. Ignoring this is asking for trouble.

-

Run a Mold Flow Analysis: Before we cut any steel, we run a simulation. This is a crucial step that I always emphasize. Mold flow analysis is like a digital test run. It shows us how the plastic will flow into the cavity, where weld lines might form, and, most importantly, how the part will cool. The simulation can highlight hot spots or areas that cool too quickly, allowing us to adjust the cooling channel design or processing parameters virtually. This saves an incredible amount of time and money by preventing problems like warpage before they happen.

-

Perform Practical On-Press Tests: Once the mold is built and in the machine, the real-world testing begins. We don’t just pick a number and run. We perform a series of structured tests. A key one is a "gate seal study," which helps determine the ideal holding time. This is directly linked to mold temperature because the gate needs to freeze to prevent material from oozing back out. A hotter mold means a longer gate seal time.

-

Bracket the Process: We start with the mold temperature set to the middle of the recommended range. We produce a small sample of parts and inspect them meticulously for dimensions, appearance, and defects. Then, we adjust the temperature down by 5-10°C, run another sample, and inspect. Then we adjust it up by 5-10°C from the midpoint and do it again. By comparing these three sets of parts, we can find the temperature that provides the best balance of part quality, dimensional stability, and cycle time.

What is the temperature control for injection molding?

You’ve finally found the perfect mold temperature, but your parts are still inconsistent from one shot to the next. This frustrating inconsistency often points to poor temperature control, where the mold temperature fluctuates during production. This undermines all your careful setup work. Implementing a robust temperature control system is the only way to ensure your mold stays at the target temperature, guaranteeing stable and repeatable quality.

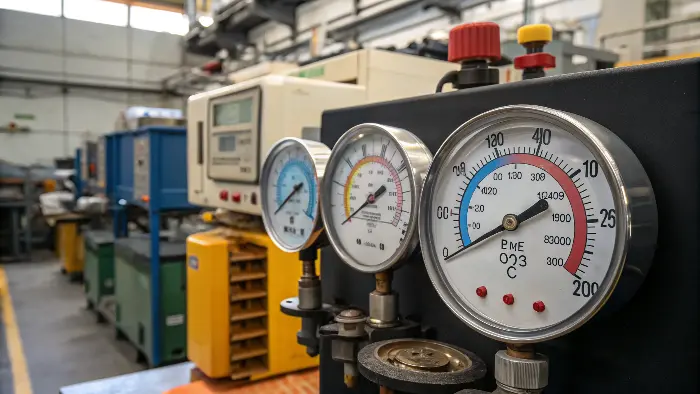

Temperature control for injection molding is achieved using a mold temperature controller, or thermolator. This unit circulates a fluid, typically water or oil, through channels within the mold to add or remove heat. Thermocouples embedded in the mold provide real-time temperature feedback to the controller, which adjusts the fluid’s temperature to maintain a stable and uniform mold surface temperature.

A stable process is a profitable process. The thermolator is the heart of mold temperature stability, but its effectiveness depends entirely on how well the mold itself is designed to use the fluid it’s being fed. This is where expert mold design becomes critical.

The Mechanics of Mold Temperature Control

The thermolator is a relatively simple but vital piece of equipment. It’s essentially a pump and a heater/chiller in one box. It constantly circulates fluid through the mold’s cooling channels to maintain a set temperature.

- Water-Based Units: These are the most common. Water is an excellent medium for heat transfer and is cost-effective. Standard units work well for temperatures up to about 90°C (194°F). For higher temperatures, pressurized water units can be used to prevent the water from boiling.

- Oil-Based Units: When processing high-temperature materials like PEEK or PC, where mold temperatures exceed 100°C, oil is used as the circulating fluid because of its much higher boiling point. These units require more careful maintenance to prevent leaks and fluid degradation.

Designing for Effective Temperature Control

At CavityMold, we know that a great thermolator can’t fix a poorly designed mold. The design of the cooling channels is just as important as the controller itself. We use our mold flow analysis results to strategically place cooling lines to ensure uniform temperature across the entire mold surface.

A key innovation here is conformal cooling.

- Conventional Cooling: In a standard mold, cooling channels are straight lines drilled through the mold block. While effective, they can’t always get close to complex part features, leading to hot spots and uneven cooling.

- Conformal Cooling: This advanced technique involves creating cooling channels that follow the exact contours of the part cavity, like a river flowing through a valley. We often use metal 3D printing to create these complex channels. The result is exceptionally uniform cooling, which dramatically reduces cycle times and minimizes warpage. I recall a project for a complex electronics housing where switching to a conformal cooling design cut the cycle time by 30% and virtually eliminated a persistent warping issue.

| Feature | Conventional Cooling | Conformal Cooling |

|---|---|---|

| Channel Design | Straight, drilled lines | Follows part contour |

| Cooling Uniformity | Moderate; can have hot spots | Excellent; highly uniform |

| Cycle Time | Standard | Can be 20-50% faster |

| Part Quality | Good; risk of warpage | Excellent; reduced stress & warpage |

| Cost | Lower initial mold cost | Higher initial mold cost |

Conclusion

In the end, analyzing and controlling injection mold temperature is not just a technical task; it’s fundamental to achieving quality and efficiency. It involves understanding the core settings, knowing the typical ranges for your material, following a systematic process to find the optimal temperature, and using robust control systems. Mastering this ensures high-quality parts, reduces waste, and is a cornerstone of mastering molding right.