Taking a product to high-volume production often means using a high-cavitation mold. But what happens when your part has undercuts requiring sliders? The complexity multiplies. A single slider failure is a problem; a failure in one of 16 or 32 cavities can shut down your entire operation, leading to massive downtime and inconsistent parts.

The solution lies in a design philosophy that anticipates the unique stresses of high-cavitation tooling. This involves robust mechanical synchronization for all sliders, advanced materials and surface treatments to combat wear, and meticulous cooling strategies. By focusing on these areas, you can ensure that every cavity produces a perfect part, cycle after cycle.

Successfully launching a high-volume product with complex geometry depends entirely on the quality and reliability of the mold. The stakes are much higher than with a single-cavity prototype tool. Let’s break down the specific challenges you’ll face and explore the proven solutions we use at CavityMold to build robust, high-performance molds that run for millions of cycles.

What are the primary challenges of using sliders in high-cavitation molds?

You’ve approved a single-cavity prototype mold with a slider, and it works great. Now, management wants to scale up to a 16-cavity production tool to meet demand. The problem is that the challenges don’t just add up; they multiply. A minor issue in one slider becomes a major production crisis when it’s replicated across numerous cavities, risking your entire investment.

The primary challenges of high-cavitation slider molds are magnified compared to single-cavity tools. You must manage perfect synchronization across all sliders, handle the accelerated wear from high cycle counts, provide adequate and balanced cooling to every slider, and fit all this complex mechanics into a constrained space while maintaining part-to-part consistency.

I’ve seen firsthand how these challenges can derail a project. The key is to address them proactively during the mold design phase. Thinking about wear, cooling, and synchronization from day one is not optional; it’s essential for the long-term success of the tool. Let’s look deeper into each of these critical areas.

The Magnified Risks of High-Cavitation

In a single-cavity mold, you have one set of components to worry about. In a 16-cavity mold, you have 16 sets. This multiplication factor applies to every aspect of the slider mechanism.

- Synchronization: All 16 sliders must actuate and retract at the exact same time. A delay in one can cause flash, while a premature movement in another can damage the mold.

- Wear and Tear: A production tool might run millions of cycles. The wear on each of the 16 sliders is immense. A weak link in any one of them can bring production to a halt.

- Cooling Consistency: Each slider is a block of steel that absorbs heat from the plastic. Each one needs its own cooling circuit. If one cavity’s slider runs hotter than the others, its part will have different dimensions and properties, leading to quality control issues.

- Space and Complexity: Fitting 16 sets of sliders, guides, locks, and cooling lines into a standard mold base is an engineering puzzle. Everything is more compact, making maintenance more difficult and design more critical.

| Challenge | Single-Cavity Mold | High-Cavitation Mold (16 Cavities) |

|---|---|---|

| Synchronization | Not applicable (one slider) | Critical; requires unified actuation |

| Wear Points | One set of components | 16 sets; failure of one stops all |

| Cooling | Simple, direct cooling | Complex; requires balanced flow to 16 circuits |

| Maintenance | Straightforward | Complex; requires careful design for access |

How do you ensure slider synchronization and alignment across multiple cavities?

You have a mold with 16 identical cavities, each with a slider. How do you guarantee they all move in perfect harmony? If one slider lags behind or moves too soon, you get inconsistent parts, flash, or even catastrophic mold damage. This synchronization is one of the biggest hurdles in high-cavitation tooling.

To ensure perfect synchronization, you must use a unified actuation system, like a single large hydraulic cylinder driving all sliders through a yoke plate, or a robust mechanical cam system. Precision alignment is maintained through high-quality guide systems and interlocking features that force each slider into the exact same position every single cycle.

In my experience, you can’t leave synchronization to chance by using individual actuators for each cavity. That’s just asking for trouble. The best approach is to design a system where a single, powerful driver controls all the sliders as one unit. This removes variation and builds reliability right into the core of the mold’s mechanics.

Choosing the Right Actuation Method

The driving force behind the sliders needs to be powerful and repeatable. There are three common methods, each with its own pros and cons for high-cavitation molds.

- Hydraulic Actuation: This is the most common method for large, heavy sliders. A single hydraulic cylinder can be connected to a "yoke" or "actuator plate" that pulls all the sliders at once. This provides immense force and ensures that no slider can move without the others.

- Pneumatic Actuation: Similar to hydraulics but using air pressure. It’s faster but provides less force. This is suitable for smaller sliders in fast-cycling molds, but ensuring equal pressure and travel across 16+ pneumatic cylinders can be challenging.

- Mechanical (Cam) Actuation: This method uses an angled pin (cam pin) that engages with the slider as the mold opens or closes. It’s highly reliable because its movement is directly tied to the press. This is excellent for ensuring timing, but it offers less flexibility than hydraulic systems.

The Importance of Guiding and Interlocks

Once the sliders are moving, they need to be guided precisely. We use hardened steel guide pins and bushings for each slider. For high-wear applications, we often use bronze or self-lubricating graphite-impregnated wear plates. These components ensure the slider moves smoothly along its intended path without any wiggle. Additionally, we design tapered interlocks on the slider and the cavity. As the mold closes, these tapers engage and lock the slider into its final, precise position, creating a perfect seal to prevent flash.

How does CavityMOLD optimize slider mechanisms for extended mold life?

A high-cavitation mold is a major capital investment, expected to run for years. The biggest threat to that investment is downtime. If a slider component wears out prematurely, the entire production line stops. This makes designing for longevity and reliability absolutely critical.

At CavityMold, we optimize for extended life by treating the slider as a high-performance machine component. This means using superior materials like hardened tool steels, applying advanced surface coatings to reduce friction and wear, and designing the system for easy maintenance with replaceable components. This approach turns a potential liability into a reliable asset.

We don’t just build molds to last; we build them to be maintained. I always tell my clients that a mold that is easy to service is a mold that will run longer. By planning for wear and making it simple to replace key components, we can significantly extend the productive life of a high-cavitation tool and maximize their return on investment.

Material Selection and Surface Treatments

The foundation of a long-lasting slider is the material it’s made from. We don’t cut corners here. For the main body of the slider, we use high-quality, heat-treated tool steels. For the components that guide the slider, we use materials designed specifically for wear resistance.

| Component | Standard Material | High-Performance Option | Benefit |

|---|---|---|---|

| Slider Body | P-20 Steel | H-13 or S-7 Hardened Steel | Resists deformation and damage |

| Wear Plates | O-1 Tool Steel | Bronze or Graphite-Plugged | Self-lubricating, reduces friction |

| Guide Pins | Hardened Steel | Hardened Steel with DLC Coating | Extremely low friction, high hardness |

On top of the base materials, we use surface treatments to further enhance performance. Coatings like Titanium Nitride (TiN) or Diamond-Like Carbon (DLC) create an ultra-hard, low-friction surface. This is like the Teflon on a frying pan; it prevents plastic from sticking and allows the slider to move effortlessly, dramatically reducing wear over millions of cycles.

Design for Maintenance (DFM)

We design our slider systems with maintenance in mind. This means:

- Using Standard Components: Whenever possible, we use standard, off-the-shelf guide pins, bushings, and wear plates. This makes finding replacements quick and easy.

- Easy Access: We design the mold so that wear components can be accessed and replaced without having to completely disassemble the entire tool. This can reduce maintenance time from days to hours.

- Clear Labeling: All components, including cooling lines for each slider, are clearly labeled. This prevents errors during maintenance and reassembly.

Can you share CavityMOLD’s approach through a complex slider case study?

All this theory is useful, but how does it apply to a real-world project? You might be looking at a complex part for a new product, wondering if it’s even feasible to produce it in high volumes. Seeing how we tackled a similar challenge can provide clarity and confidence.

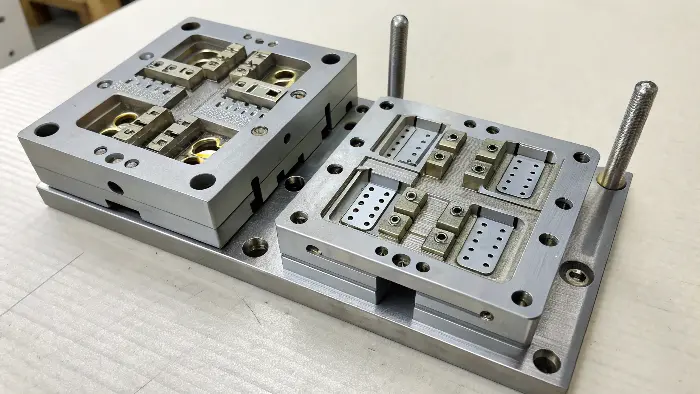

Let me walk you through a recent project. We were tasked with building a 16-cavity mold for a small electronics connector. The part had external snap-fit latches and an internal clip, requiring two separate slider actions in each cavity. The challenge was to make it all work reliably in a very compact space.

This project brought together all the principles we’ve discussed: unified actuation, advanced materials, and meticulous design for maintenance. The client needed millions of parts per year with extremely tight tolerances, so there was no room for error.

The Challenge: A Dual-Action Slider in 16 Cavities

The part was a small connector housing made from a rigid, glass-filled PBT. It had undercuts on the sides (latches) and another undercut inside the connector port. This meant we needed two different sliders per cavity, moving in different directions.

- Slider 1 (Lifter): An internal lifter, which is a type of slider that moves at an angle as the mold opens, was needed to form the internal clip.

- Slider 2 (Side-Action): Traditional horizontal sliders were needed for the external latches.

- The Problem: We had to synchronize 16 lifters and 16 side-action sliders in a single mold base, ensuring they all moved in the correct sequence without interfering with each other.

Our Solution: Integrated Design and Simulation

First, our DFM team worked with the client to add a bit more draft to the internal clip, which made the lifter’s job easier. Then, we designed an integrated system. The 16 side-action sliders were all connected to a single hydraulic actuator plate for synchronized movement. The 16 lifters were actuated by the mold opening, but we designed them to ride along the locked side-action sliders. This created a sequence: the mold opens slightly, the lifters form the internal feature and retract, then the hydraulic system pulls the side-action sliders, and finally, the part is ejected.

Before cutting any steel, we ran extensive mold flow and mechanical simulations. The simulation confirmed that our integrated system would move correctly and that all 16 cavities would fill and cool evenly. For materials, we used hardened H-13 steel for all sliders and lifters, with a low-friction DLC coating on all moving surfaces to ensure a 2-million cycle life. The result was a robust, fast-cycling production tool that delivered consistent, high-quality parts from day one.

Conclusion

High-cavitation molds with sliders present a significant engineering challenge, but they are not insurmountable. Success depends on a holistic design approach that prioritizes synchronization, wear resistance, and thermal management. By using unified actuation, selecting advanced materials and coatings, and designing for maintenance, we build tools that perform reliably for millions of cycles, ensuring our clients meet their production goals.