Introduction to Injection Molding

Injection molding is one of the most significant processes in the industry. It allows for the production of complex structures with good precision and reproducibility. Its application extends to microelectronics, biomedical, automotive, and aerospace amongst others. The desirable property of materials like metals and plastics is how they form. When cooled they keep the new structures into which they have formed. Injection molding is also applied to thermoset materials. These are materials that do not melt upon heating. Instead, they go from viscous liquid to a solid-state through the process of crosslinking. Materials such as metals, rubbers, plastics, and glass can be injection molded. It allows for large scale production of products in repeated cycles.

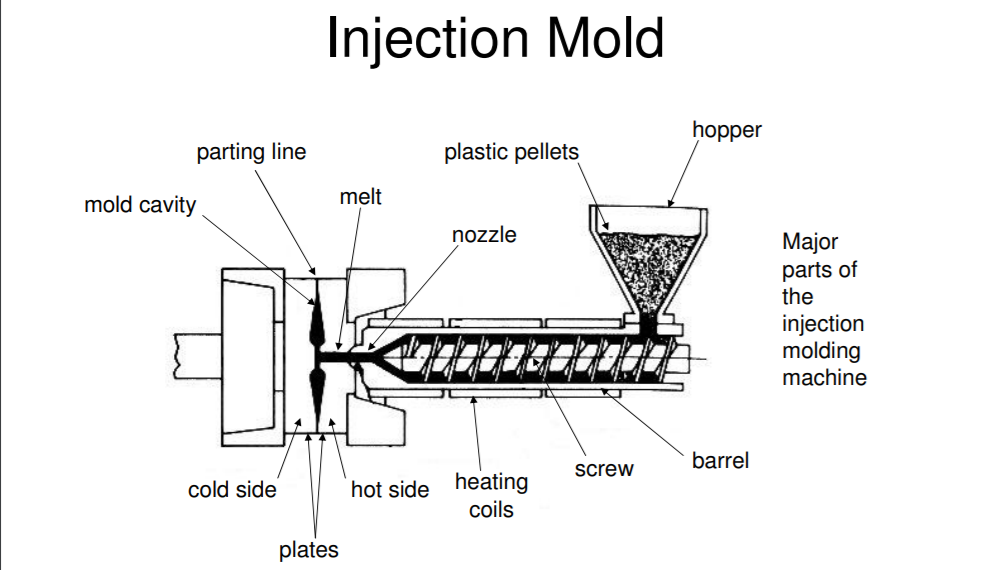

Injection molding machines are the injection and clamping sections. The injection section comprises a screw, barrel, valves, and control units. The clamping section comprises the sprue, runner, gates, and the mold and cooling unit. The material mixes and melts in the injection section. This melt is then compressed and cooled in the clamping section. The process can be fully automated, semi-automated, or manual. The fully automated system would include temperature controllers, automated ejectors, and metering. The manual processes may need the opening of the mold by hand. The ejection of the cooled product may also be by hand in the manual types.

The following paragraphs describe the injection molding machine. Then a description of the process of injection molding. Later paragraphs discuss the different types, advantages, and disadvantages. Such a fundamental understanding of the injection molding helps the operation and design.

The Injection Molding Machine

A typical injection molding machine consists of the following parts:

- Screw

- Barrell

- Heaters

- Limit switch

- Check valve

- Sprue

- Runner

- Gate

- Mold

- Cooling lines

The injection molding machine performs the role of melting, injecting, and holding. The main component of doing most of the work is the screw. In injection molding, the screw is a reciprocating screw. It moves forward and backward at specific points during the cycle. It applies sheer through torque as it rotates. The screw is in a barrel and the plastic pellets to form the new products feed into the barrel from the hopper. The barrel heats with electric heaters. These are along its length and this heat gets to the pellets and the screw. The product forms within the mold cavity attached to the nozzle of the barrel via a sprue. The sprue feeds the runner, this then feeds the molten material into the mold cavity through the gate.

The mold forms the molten material into the desired shape. Steel is often used for the production of the injection molding parts. The mold cavity size includes consideration for shrinkage. The shrinkage is a characteristic of the material used. For example, while high-density polyethylene has a shrinkage of 3%, that of polypropylene is 2% and that of PET is 0.4%. The shrinkage occurs due to the reordering of the crystal structure of the molecules. This reordering occurs as the material transitions from the molten phase to the solid phase. The shrinkage is also as a result of a change in enthalpy and entropy in the material.

Process Overview

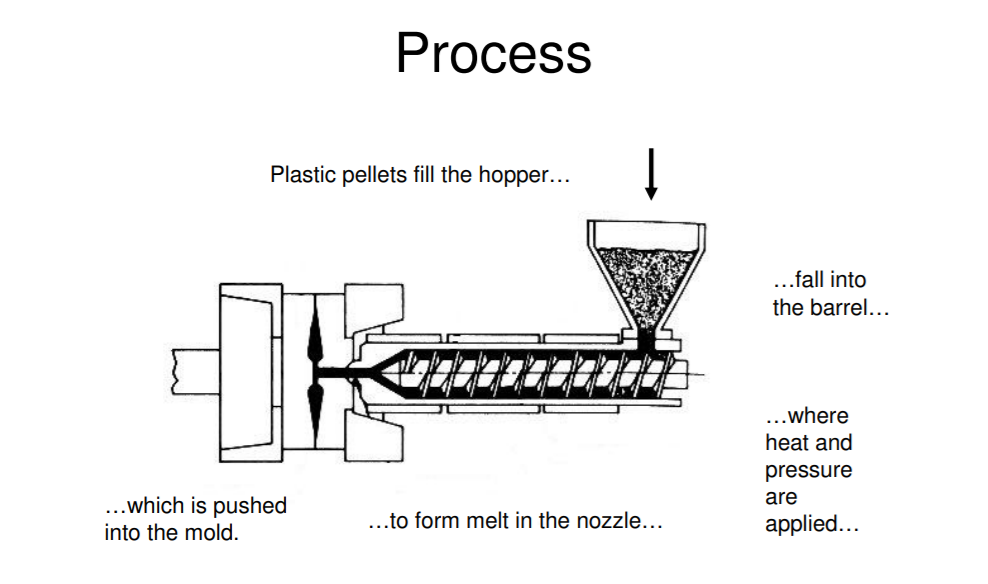

Injection molding is a cyclic process. This means the process will occur as a sequence of events repeated in the same manner. A cycle begins with the mold closed. The material in pellet form goes into the hopper. The screw rotates and moves backwards. The pellets melted and the melt pushed forward along the barrel into the melt chamber.

The melting of the pellets is as a result of the heated walls of the barrel. The heat from friction between the rotating screw and the barrel also contributes. This continues until the screw reaches the limit switch. The limit switch indicates that the required shot size is in the melt chamber. The shot size refers to the amount of molten material required to fill the mold cavities in one cycle. This includes allowances for shrinkage, runner, and retained amount in the chamber. The melt chamber refers to the space between the screw end and the nozzle. The nozzle feeds the melt into the runners and molds.

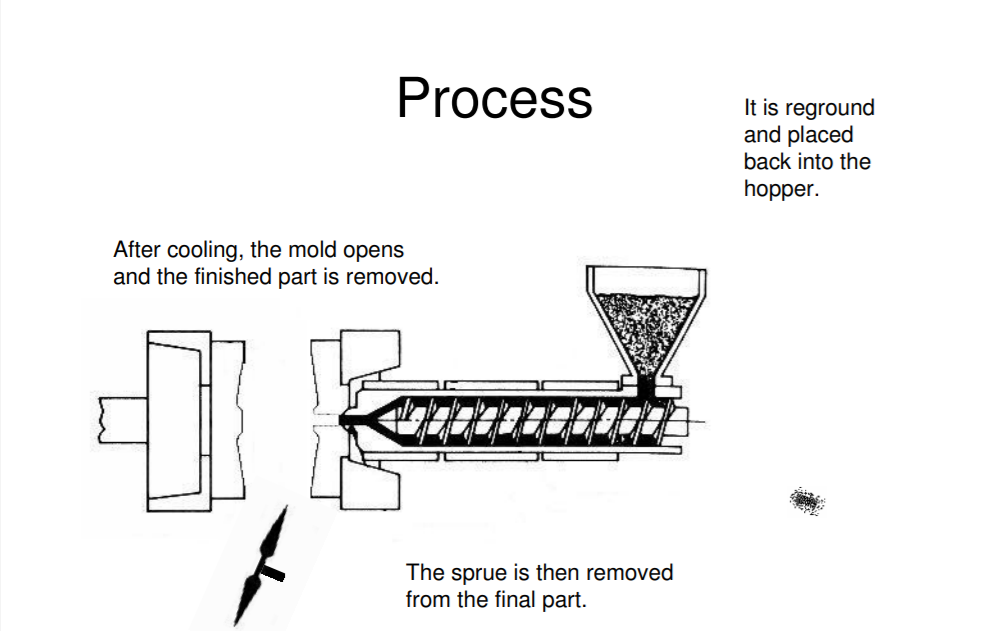

The screw reaches the limit switch and stops moving back. It then moves forward at high velocity and pressure by hydraulic force. This injects the melt from the melt chamber into the mold cavity. A check valve prevents the melt from flowing backward by a check valve. The mold is then held at this pressure and cooling. The cooling is by cooling fluid supplied through cooling lines. Precooled mold allows for faster cooling and more effective product forming. Once cooled the mold opens and the product ejects from the mold cavity by ejector pins. The release of the product is also in part aided by the shrinkage. Particularly in plastics where the cooled product can shrink to as much as 3% of the melt volume. As the mold cools the screw begins to move backward and the next cycle begins.

The goal of injection molding is to achieve controlled heating, forming, and cooling. This should be in a minimal amount of time with optimal efficiency and no defects. This is with the use of several control systems. The parameters include speed, temperature, velocity, time amongst others. The speed of rotation of the screw is in rotation per minute (rpm). The temperature within the barrel and the temperature in the mold. The pressure and velocity of filling. The holding pressure and temperature in the mold cavity. Control of the process parameters is crucial to achieving optimal quality and productivity. Ancillary devices include motor, gear reducer, and temperature control units.

Advantages of Injection Molding method

The advantages of injection molding include production of complex structures with good precision. The scalability of the process is also important. The process scale-up is by increasing the number of molds per cycle. The process is also reproducible. Thus allowing for identical products made in large quantities.

The complexity achieved in injection molding would otherwise take several hours per piece. Processes such as ordinary machining and sculpting cannot achieve the same output volume. Examples of items that can be produced by injection molding are vast. Knobs, screws, chairs, buckets, plant pots, medical tools, footwear are among them.

Injection molding also has the advantage of short cycle times. This allows for a large scale production rate. Typical cycle times are between 10 and 30 seconds or even less. The cycle time begins from the moment the mold shuts and the screw begins to fill the melting chamber. The cycle ends when the mold fills again.

Versatility of injection molding is also an advantage. The machine is adapted to produce different products by changing the molds. Size of products vary as required. This can be from small articles such as screws and bolts to large articles such as chairs and vehicle parts. Injection molding can achieve complex 3 dimensional structure with detailed precision. It does this better when compared to processes such as compression molding.

Disadvantages of Injection Molding Method

Like other processes, injection molding also has its disadvantages. One of the inherent disadvantages is that it is a cyclic and not a continuous process. This poses some limitations such as the time required for cooling. A well-designed process and machinery reduce the time for ejection and cooling… This nonetheless adds more time to the process.

The use of a mold minimizes the loss of the material. This is unlike compression molding where the mold fills to excess. This is to ensure that the product forms completely. The excess results in the formation of scraps. Injection molding also generates scraps in the sprue and runner. Especially in the cold runner types.

The mold plays an important role in the injection molding process. The design of a mold for injection molding high capital cost. This is because the mold needs good quality metal. This is to keep the pressure required for injection and for holding the melt in place during cooling. Compression molding uses less expensive materials such as wood. But, these do not achieve the 3 dimensional precision of injection molding process.

Types of Injection Molding

The variation in injection molding lies in the properties of the materials used. The melting point, melt viscosity, glass transition temperature, shrinkage, and density are some. Injection molding is classified in different ways. One is on the basis of the number of molds. Injection molding can be a single cavity or multi-cavity systems. The single cavity system is for injection molding of very large parts. Examples are large equipment or vehicle parts. For smaller products, multi-cavity systems are used. With these several pieces produce per cycle. This allows for an economy of scale where many pieces are made in seconds

Classification can also by the type of material. Examples are thermoplastic, thermoset, metal, Powder, or glass injection molding. Although these use the same fundamental process of injection molding there are some variations. In the plastic injection molding, melting, and forming are with heat and pressure. In the thermoset injection molding, forming is by crosslinking within the mold. Thermoset cross-linking can at room temperature or at elevated temperature. Some need conditions such as UV light irradiation may. Thermoplastic injection molding is less complex than thermoset injection molding. The latter has the difficulty of ensuring that the crosslinking only occurs in the mold. Equipment and product could get damaged if the polymer cures it reaches the mold cavity.

Metals are also processed using injection molding. This can be either through powder injection molding or metal injection molding. Referred to as PIM or MIM respectively. The metal injection molding process uses much finer metal particles. The smaller particle size results in a higher surface area. The larger surface area results in more effective heat exchange and distribution. This means that less heat energy input is needed to reach the melting point of the metal. Additionally, the smaller particle size will allow for better compacting. This results in a higher density of the product. Finer powder requires more demanding processing. Thus MIM tends to be more expensive than the PIM process. Furthermore, the PIM process can be a combination of metal, ceramic, and a binder. The binder degrades in the de-binding and sintering process. This also leads to decreased volume and increased density. Metals such as steel, aluminum, copper, tungsten, and titanium amongst others.

Another classification of injection molding is to do with porosity. Such methods include gas-assisted injection molding and structural foam molding. The former involves the passing of air at high pressure through the mold cavity. This creates a hollow center and a dense wall. The latter involves even distribution of gas in the molded article to create pores.

Injection molding can also be on the type of runner system used. These are cold and hot runner injection molding. The type of cooling system used in the clamping section of the injection molding machine. Other articles discuss the hot and cold runner systems in more detail in other articles. All these aids in determining the right injection molding process and machinery required. The processor must have a good knowledge of the material. The target product design, application, and budget are also important factors to consider.

Conclusion

In conclusion, the injection molding process is a versatile process. It processes various materials into a wide range of products. It achieves high volume, high speed, and low-cost production of intricate parts. In injection molding, the materials experience high shear and high temperature. The processing temperature is usually close to the melting point of the material.