Tired of seeing molding only in simple items? It’s time to see its vast, unseen industrial power. This changes everything, you know?

Injection molding is crucial far beyond consumer goods. It’s key in automotive, medical, construction, and industrial packaging, making complex, durable parts efficiently. This technology is pretty much everywhere, even if you don’t always spot it!

You know, it’s easy to spot injection molded parts in the things we use every day, like our phone cases or the kids’ toys. But I’ve been in this business – here at CavityMold – since we started back in 2009, and let me tell you, the real magic, the stuff that keeps industries ticking, often happens behind the scenes. It’s like an unsung hero, really. So, I want to pull back the curtain a bit and show you just how deep this whole injection molding thing goes. Alex, as a project manager, I bet you’ve seen some of this, but maybe there are a few surprises in store for you too! It’s always amazing to see where these parts end up.

How Does Injection Molding Keep Our Cars Running and Looking Good?

Car parts breaking down is a total nightmare, right? Complex or unreliable components can cause so many headaches for manufacturers and car owners alike. But precision molding offers a really dependable, and often more cost-effective, solution for the auto industry.

Injection molding produces tons of essential automotive parts like dashboards, bumpers, interior panels, and even critical engine components. It ensures high precision, durability, and helps reduce weight, which is super important for performance and fuel efficiency. Seriously, cars are packed with this stuff.

When you think about it, the automotive world demands so much. Parts need to be tough, they need to fit perfectly, and these days, they need to be as light as possible. That’s where we, as mold makers, really get to shine. I remember a project we did a few years back for a European car manufacturer. They needed a really intricate housing for an engine sensor. The tolerances were incredibly tight, and the material had to withstand high temperatures and vibrations. It was a challenge, for sure, but seeing that part come off the line perfectly, knowing it was going into thousands of cars – that was satisfying.

Precision Parts Under the Hood

You might not see them, but under the hood of almost any modern car, there are dozens of injection molded parts. We’re talking about things like intake manifolds, fluid reservoirs, cooling fan shrouds, and various covers and brackets. These aren’t just simple plastic bits; they are engineered components made from materials like glass-filled nylon (PA) or polypropylene (PP) that can handle heat, chemicals, and mechanical stress. The precision here is key – if an air intake part doesn’t seal properly, engine performance suffers. It’s pretty critical stuff.

Making Car Interiors Comfortable and Functional

Then you get inside the car. So much of what you touch and see is injection molded. Dashboards, door panels, center consoles, seat belt components, even the little clips that hold everything together. Using materials like ABS, PC/ABS blends, or TPEs for soft-touch surfaces, manufacturers can create complex shapes with great surface finishes. This allows for amazing design freedom while keeping things durable and cost-effective. Think about all the buttons, knobs, and air vents – each one perfectly formed.

Safety First: Exterior Components

And don’t forget the outside! Bumpers, grilles, light housings, and even some body panels can be made using injection molding. These parts need to be strong, impact-resistant, and able to withstand whatever the weather throws at them. Materials like TPO or PC/PBT are common here. Plus, molding allows for aerodynamic shapes that help with fuel economy. It’s a pretty big deal for safety and efficiency.

Can Tiny Molded Plastics Really Make a Big Difference in Healthcare?

Medical errors or device failures? That’s the stuff of nightmares in healthcare. So, when you’re making parts for medical applications, there’s just no room for error. Injection molding steps up to provide the incredible precision and sterility needed for life-saving medical components.

Absolutely! Injection molding creates critical medical devices: syringes, drug delivery components, diagnostic tool parts, and even some implants. It meets incredibly strict hygiene, biocompatibility, and precision standards essential for patient safety. It’s a total game-changer in medicine.

The medical field is one area where I feel our work at CavityMold has such a direct, positive impact. The standards are, rightly, sky-high. We’re talking about parts that might go inside someone’s body, or deliver life-saving medication. I recall one particularly complex project involving a microfluidic chip for a diagnostic device. The channels in that chip were thinner than a human hair! The precision required was just astounding. We had to use specialized PEEK material, and the mold itself was a work of art. Knowing that our molds help produce devices that improve or save lives – well, that’s a pretty good feeling at the end of the day. It’s more than just plastic; it’s about patient well-being.

The Lifesaving Precision of Medical Devices

Think about it – a slight imperfection in a syringe barrel could affect dosage. A poorly molded catheter component could cause serious complications. That’s why precision is non-negotiable. Injection molding allows for the consistent production of highly complex, intricate parts with tolerances measured in microns. This consistency is vital for devices like insulin pens, inhalers, and surgical instruments. Every single part has to be perfect, or as close to it as humanly possible.

Materials That Matter: Biocompatibility and Sterilization

The materials used in medical molding are also super specialized. They often need to be biocompatible, meaning they won’t cause an adverse reaction when in contact with the human body. Think medical-grade polycarbonate (PC), polystyrene (PS), polypropylene (PP), or even advanced polymers like PEEK or PSU. These materials also need to withstand various sterilization methods – like autoclaving, gamma radiation, or ethylene oxide (EtO) – without degrading or losing their properties. It’s a whole science in itself.

From Labware to Surgical Tools: The Scope

The range of applications is just huge. You’ve got disposable items like petri dishes, test tubes, and pipette tips, all mass-produced with incredible accuracy. Then there are more complex components for diagnostic equipment, housings for pacemakers, parts for dialysis machines, and even custom-molded surgical guides. It’s a field that’s always innovating, and injection molding is right there, making those innovations possible.

Is Injection Molding Secretly Building Our World, Piece by Piece?

Construction projects are notorious for delays and going over budget, aren’t they? And if you use weak or unsuitable materials, you’re just asking for long-term problems. But guess what? Injection molded components are increasingly offering durable, affordable, and often easier-to-install alternatives in the building industry.

Yes, it plays a surprisingly huge role! Injection molding produces things like pipe fittings, electrical conduits and boxes, window components, insulation panels, and even safety gear for workers. These parts are tough, weather-resistant, and usually very cost-effective.

It might not be as glamorous as automotive or medical, but the construction industry relies heavily on injection molded parts for some very practical reasons. I remember a client approached us a while back; they were developing a new modular building system. They needed custom-designed connecting fixtures that were incredibly strong but also lightweight and easy to handle on-site. We worked with them to select a robust, UV-stabilized engineering plastic and designed a mold that could produce these parts with high precision and repeatability. Seeing those parts help put up buildings faster and more efficiently – that’s pretty cool. It’s all about finding smart solutions for everyday challenges.

Strong Foundations: Structural and Utility Components

When you look at the guts of a building – the plumbing, the electrical systems – you’ll find a lot of injection molded parts. Think PVC or CPVC pipe fittings, PEX tubing components, electrical junction boxes, and conduit connectors. These parts need to be durable enough to last for decades, often buried in walls or underground. Injection molding allows for complex shapes that ensure watertight or secure connections, which is absolutely critical for the integrity of a building. Materials like PVC, HDPE, and PP are workhorses here.

Weathering the Storm: Durability in Building Materials

Then there are parts exposed to the elements. Window frames and profiles, guttering components, roofing tiles, and even decorative exterior elements can be made from weather-resistant plastics like uPVC or ASA. These materials won’t rot, rust, or corrode like traditional materials, and they often offer better insulation properties. Plus, they can be molded in various colors and textures, reducing the need for painting or other finishing processes. This durability means less maintenance and a longer lifespan for the building components.

Safety on Site: Molded Gear for Protection

And let’s not forget the people doing the building! Safety equipment is paramount on any construction site. Hard hats, safety goggle frames, and components for harnesses are often injection molded from high-impact plastics like HDPE or ABS. These items need to meet stringent safety standards, and molding allows for designs that are both protective and comfortable enough for workers to wear all day. It’s a small but vital contribution to a safer working environment.

Beyond Cereal Boxes: How Does Molding Handle Heavy-Duty Industrial Packaging?

Product damage during shipping or handling is a massive headache and can be incredibly costly, right? Flimsy or inadequate packaging can lead to major losses, especially when you’re dealing with valuable industrial goods. Robust, custom-designed injection molded packaging is often the unsung hero that protects these items effectively.

Injection molding creates strong, often reusable containers, pallets, dunnage trays, caps, and closures specifically for industrial goods. It ensures product safety during transit, allows for efficient handling and storage, and can even boost sustainability through reusability.

I think people often associate plastic packaging with single-use consumer items, but in the industrial world, it’s a whole different ball game. We once worked with a large electronics manufacturer who was having issues with damage to sensitive components during inter-facility transport. We helped them design custom-molded dunnage trays from a durable, anti-static plastic. Each tray perfectly cradled the components, preventing movement and impact. The result? A huge reduction in damage and significant cost savings for them. That’s the power of smart, molded industrial packaging – it’s all about protection and efficiency.

Protecting the Goods: Custom Containers and Crates

For transporting bulk materials, components, or finished industrial products, injection molded crates, totes, and bins are fantastic. Made from tough materials like HDPE or PP, these containers can be designed to be stackable, nestable (to save space when empty), and even compatible with automated handling systems. They can withstand rough handling and repeated use, unlike, say, cardboard boxes in many heavy-duty situations. Plus, you can mold in features like handles, label areas, or even RFID tag slots.

Efficiency in Logistics: Pallets and Handling Solutions

Plastic pallets are another big one. While wood pallets are still common, injection molded plastic pallets offer a lot of advantages. They are more durable, easier to clean (which is crucial for industries like food processing or pharmaceuticals, even on an industrial scale), lighter, and have consistent dimensions. This consistency is great for automated warehousing systems. They don’t splinter or leave debris, which is a plus for cleanliness and safety. It might seem simple, but a good pallet makes a world of difference in logistics.

The Cap on Top: Secure Closures for Industrial Products

And don’t forget the closures! For industrial drums, containers, and pails holding anything from chemicals to food ingredients, you need secure, reliable caps and lids. Injection molding can produce these with precise threads, tamper-evident features, and seals that ensure product integrity and prevent leaks. Different materials can be chosen based on chemical resistance or food-grade requirements. It’s a small part, but a very important one for safety and quality.

Are My Industrial Machines and Complex Gadgets Also Full of Hidden Molded Parts?

Machine downtime is a project manager’s worst nightmare, Alex, I’m sure you’d agree! When intricate parts fail, it can bring entire production lines to a screeching halt. This is where precision molded components become so vital, ensuring reliability and peak performance in complex industrial equipment and even sophisticated electronic devices.

Definitely! Many industrial machines and complex electronics heavily rely on custom injection molded internal components, robust housings, and specialized connectors. These parts are chosen for their precision, durability, and specific material properties that are essential for demanding applications.

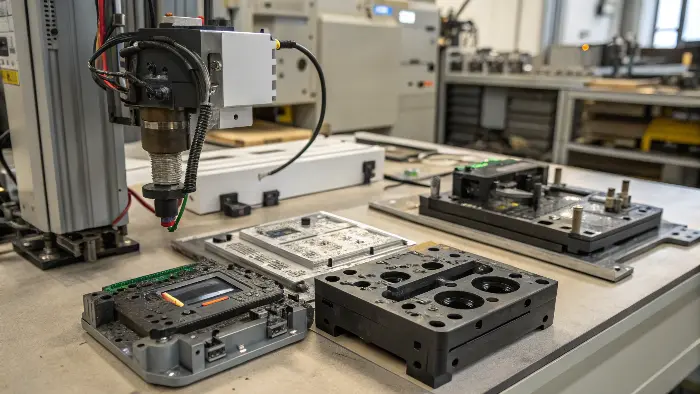

This area is where the lines can sometimes blur, because yes, some electronics are "consumer" products, but the components inside them, or the machines that make them, are often full of industrial-grade molded parts. I recall an aerospace client – talk about demanding! They needed some highly specific internal brackets and connector housings. The material had to be lightweight yet incredibly strong, and flame retardant. We worked with an advanced PEEK-like polymer. The complexity of the mold to achieve the near-net-shape parts was intense. But it’s these hidden heroes, these precisely engineered plastic parts, that allow such complex machinery and devices to function reliably day in, day out.

The Guts of the Machine: Internal Precision Parts

Inside many industrial machines – whether it’s manufacturing equipment, robotics, or even power tools – you’ll find a host of injection molded gears, cams, levers, bushings, and other mechanical components. These parts often replace metal ones because plastics can offer self-lubrication, noise reduction, corrosion resistance, and weight savings. Engineering plastics like Acetal (POM), Nylon (PA), or PBT are commonly used for their excellent mechanical properties and dimensional stability. The ability to mold complex geometries means fewer assembly steps too.

Housings and Enclosures: Protecting Sensitive Equipment

Sensitive electronic controls, power supplies, and sensor arrays in industrial settings need robust protection from dust, moisture, impact, and sometimes even chemicals. Injection molded enclosures and housings made from materials like ABS, polycarbonate (PC), or glass-filled plastics provide this protection. They can be designed with features like EMI/RFI shielding, gasket seals for IP ratings, and integrated mounting bosses. This ensures the delicate electronics inside keep working, no matter the environment. Think about the control panel on a CNC machine – that sturdy casing is likely molded.

Connectivity and Control: Molded Connectors and Interfaces

Electrical connectors, terminal blocks, and switch components are also frequently injection molded. The insulating properties of plastics are obviously key here, but so is the ability to create intricate shapes that ensure secure connections and prevent short circuits. Materials like PBT, PPS, or high-temperature nylons are often chosen for their electrical properties and ability to withstand soldering temperatures. Even the buttons and knobs on control interfaces are precision molded for a good user experience and durability. It’s all about reliable connections and user interaction.