Choosing acrylic seems easy, but the wrong grade tanks your project. Costs rise, performance drops. We’ll guide you to the perfect PMMA, ensuring success every time.

Selecting the right acrylic involves matching material properties like impact strength, light transmission, UV resistance, and melt flow rate to your project’s specific mechanical, optical, and processing demands. Prioritize end-use requirements.

Alright, Alex, you know acrylic is a fantastic material – clear, often pretty tough, and it can look amazing. But "acrylic" isn’t just one thing, is it? It’s like saying "metal" – there are tons of different types for different jobs. Choosing the right grade of Polymethyl Methacrylate, or PMMA as we call it, can be the difference between a product that sings and one that, well, falls flat. I’ve seen it happen! Someone picks a general-purpose grade for an outdoor application, and then wonders why it’s yellowing after a year. Or they choose a super high-flow grade for a thick-walled part and struggle with sink marks. At CavityMold, we’re all about "Master Molding Right," and that starts way back with material selection. So, let’s dive into how you can navigate the world of PMMA grades and pick a winner for your next project. Trust me, getting this right upfront saves a world of pain later. It’s a bit like cooking – the best recipe won’t save you if you use the wrong kind of flour!

What Key Properties Should Drive Your Acrylic Grade Choice?

Project demands are unique; a generic acrylic won’t cut it. Performance suffers, headaches begin. Understanding core PMMA properties aligns material choice with your specific application needs.

Focus on impact strength for durability, light transmission for clarity, UV stability for outdoor use, and chemical resistance for harsh environments. These core properties dictate suitability and performance in the end product.

When we start a new project with a client like you, Alex, the first thing we do is a deep dive into the application. It’s not just "what are you making?" but "how will it be used?" "What environment will it live in?" "What stresses will it face?" The answers to these questions point us directly to the critical material properties. For instance, if you’re designing a display cover for a ruggedized tablet, impact strength is going to be way up on your list. But if it’s a lens for an internal sensor, light transmission and optical clarity might be the non-negotiables.

Let’s break down some of these key properties:

- Mechanical Strength: This isn’t just one thing. We look at:

- Impact Strength (Izod or Charpy): How well does it resist sudden shocks or drops? This is crucial for anything handheld or likely to get bumped.

- Tensile Strength: How much pulling force can it take before it stretches or breaks? Important for parts under constant load.

- Flexural Strength: How well does it resist bending? Think shelves, or long, unsupported parts.

- Optical Properties: If your part needs to be clear or transmit light, these are vital:

- Light Transmission: Usually expressed as a percentage, how much light passes through? Standard PMMA is excellent, often around 92%.

- Haze: How much does it scatter light, making things look cloudy? Lower is better for clarity.

- Refractive Index: How much does it bend light? Critical for lens design.

- Thermal Properties:

- Heat Deflection Temperature (HDT): At what temperature does it start to soften or deform under a load? Super important if your part is near a heat source, like an LED, or used in a hot environment.

- Environmental Resistance:

- UV Stability: Will it be used outdoors? If so, you need a UV-stabilized grade to prevent yellowing and degradation from sunlight. I’ve seen parts go brittle and crack because the wrong grade was used outdoors – not pretty.

- Chemical Resistance: What chemicals will it encounter? Cleaning agents? Solvents? PMMA is good with some, but not others (e.g., it doesn’t like ketones or aromatic hydrocarbons).

- Melt Flow Rate (MFR) or Melt Volume Rate (MVR): This is more for us molders, but it impacts part design. It tells us how easily the molten plastic flows. A high MFR is good for thin-walled, complex parts, while a lower MFR might be better for thicker sections to control sink and voids.

Thinking through these helps narrow down the field considerably. It’s a bit like detective work – gathering clues to find the perfect suspect… I mean, material!How Do Additives and Special Formulations Tailor Acrylic for Specific Needs?

Standard PMMA is great, but what if you need more? Generic grades limit potential. Special formulations and additives unlock enhanced performance for unique, demanding applications, really pushing boundaries.

Additives like UV inhibitors boost weatherability, impact modifiers increase toughness, and colorants provide aesthetics. Special grades can offer enhanced scratch resistance, light diffusion, or even antimicrobial properties for specific end-uses.

Now, Alex, the base PMMA resin is already pretty impressive, but sometimes a project throws a curveball that standard grades can’t quite handle. That’s where the magic of additives and special formulations comes in! Think of it like customizing a car – you start with a good chassis, but then you add features for performance, comfort, or looks. We do the same with acrylic. For instance, I had this client who was making outdoor signage. Beautiful, intricate designs. Standard PMMA would look great for a while, but we knew the sun in their location was brutal. So, we immediately steered them towards a PMMA grade with high levels of UV stabilizers. It cost a bit more per kilo, sure, but the longevity it offered made it a no-brainer.

Here are some common ways we can tweak PMMA:

- UV Stabilizers: As mentioned, these are crucial for outdoor applications or even indoor ones with significant UV exposure (like near certain types of lighting). They absorb or block UV radiation, preventing the polymer chains from breaking down.

- Impact Modifiers: If you need more toughness than standard PMMA offers – maybe for a protective cover or a part that might get dropped – impact-modified grades are the way to go. These often involve blending PMMA with rubbery impact modifiers. The trade-off can sometimes be a slight reduction in clarity or gloss, but the gain in durability is often worth it.

- Colorants and Pigments: This is an obvious one, but it’s so important for branding and aesthetics. PMMA can be colored to almost any shade imaginable, from transparent tints to opaque, vibrant colors. We work with precise masterbatches to ensure color consistency from batch to batch – critical for consumer products.

- Light Diffusers: For applications like LED lighting covers or backlit displays, you often want to diffuse the light to avoid hotspots and create a smooth, even illumination. Special PMMA grades incorporate light-diffusing particles to achieve this. We once did a project for an architectural lighting feature, and getting that perfect, soft glow was all down to selecting the right diffuser grade. It was a game-changer for the final look.

- Scratch-Resistant Coatings/Grades: While PMMA is harder than many plastics, it can still scratch. For high-touch surfaces or premium products, you can opt for PMMA grades with enhanced scratch resistance or apply a hard coat as a secondary operation.

- Anti-Static Agents: In electronics or environments where dust is an issue, static build-up can be a pain. Anti-static additives can be incorporated into the PMMA to help dissipate static charges.

It’s all about understanding the specific challenge and knowing which tool – or in this case, additive – to pull from the toolbox. This is where our experience at CavityMold really helps guide our clients.When is an Optical Grade PMMA Absolutely Essential for Your Project?

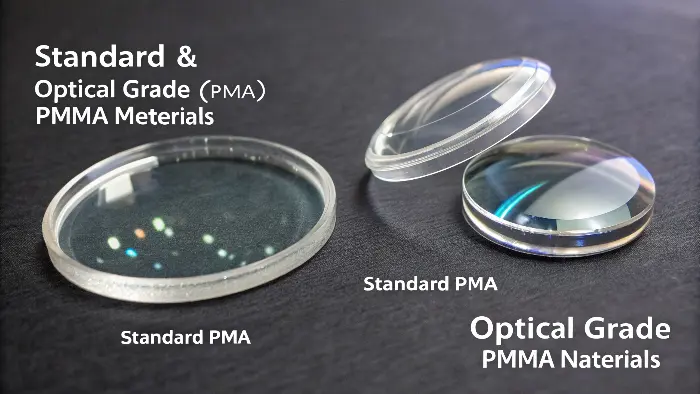

Your lenses are blurry, light guides dim – a disaster! Standard PMMA won’t suffice. For critical optical performance, only specialized optical grade acrylic delivers the needed pristine clarity and consistency.

Optical grade PMMA is crucial for applications like high-precision lenses, critical light pipes, medical diagnostic components, and high-clarity display screens. It offers superior light transmission, minimal haze, and strict batch-to-batch consistency for reliable optical performance.

Alex, let’s talk about when "good enough" just isn’t good enough, especially when light is involved. For many general applications, standard PMMA’s clarity is perfectly fine. But when you’re dealing with serious optical components – things like lenses, prisms, high-performance light guides, or critical windows for sensors and medical diagnostic equipment – then you absolutely need to step up to an optical grade PMMA. It’s a whole different ball game. I remember a project where a client was developing a new type of scanner. They initially tried a general-purpose clear PMMA for a critical lens element to save costs. The prototypes just weren’t performing; the image quality was fuzzy, and readings were inconsistent. We suspected the material. After switching to a certified optical grade PMMA, boom! The difference was night and day. The clarity, the precision – it all snapped into focus.

So, what makes optical grade PMMA special?

- Exceptional Purity: These grades are manufactured under much stricter conditions to minimize any contamination, internal defects, or "gels" that could scatter or absorb light. Think of it like the difference between regular window glass and the glass used in a high-end camera lens.

- Maximum Light Transmission & Minimal Haze: Optical grades are optimized for the highest possible light transmission (often >92%) and the lowest possible haze values. This means more light gets through, and it gets through cleanly without being diffused or distorted.

- Tight Refractive Index Control: For lens designers, knowing the exact refractive index of the material is critical for calculating how light will bend. Optical grades offer very tight tolerances on this property, ensuring consistent optical performance from part to part and batch to batch.

-

Batch-to-Batch Consistency: This is huge. When you’re making thousands of optical components, you need to know that the 10,000th part will perform identically to the first. Optical grade resin suppliers provide much more detailed certifications and guarantee this consistency.

The applications are pretty clear-cut:Application Category Examples Why Optical Grade? Imaging Optics Simple lenses, magnifiers, sight glasses Clarity, Refractive Index Light Transmission Fiber optic terminations, light pipes for data Max Transmission, Low Loss Medical Devices Cuvettes, diagnostic slides, optical sensors Purity, Consistency, Clarity High-Clarity Displays Protective screens, specialized touch panels Low Haze, No Distortion Yes, optical grades are more expensive, but if the function of your product hinges on pristine optical performance, it’s an investment, not an expense. Trying to skimp here is almost always a false economy, Alex. We’ve seen it!

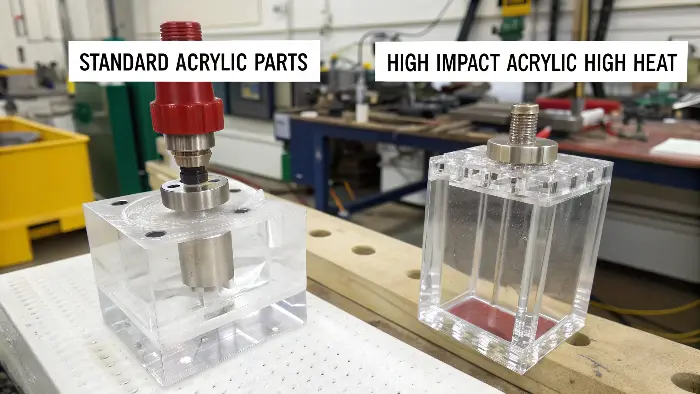

Are High-Impact or High-Heat Acrylic Grades Worth the Extra Cost?

Parts breaking or warping under stress? Standard acrylic failed you. High-impact or high-heat grades offer robust solutions when an application demands superior toughness or thermal stability.

Yes, they are worth it for demanding applications. High-impact grades suit parts needing durability against drops or knocks. High-heat grades prevent deformation in hotter environments, like near light sources or in automotive interiors.

This is a classic cost-benefit question, Alex, and it comes up all the time. Standard PMMA is pretty good, but it does have its limits in terms of toughness and how much heat it can take. So, what happens when your application pushes those limits? That’s when we start talking about high-impact or high-heat acrylic grades. And yes, they generally come with a higher price tag per pound or kilo. The key is to understand if the value they bring in terms of performance and reliability justifies that extra cost. More often than not, if the need is genuine, the answer is a resounding yes.

Let’s look at them separately:

- High-Impact PMMA:

- What is it? These grades are typically PMMA copolymerized or blended with an impact modifier, often a rubber-based material. This introduces a toughening mechanism that helps the material absorb and dissipate impact energy, making it much less prone to shattering or cracking compared to general-purpose acrylic.

- When to use it? Think about applications like point-of-sale displays that get knocked around, machine safety guards, skylights that might face hail, or housings for portable devices. I once worked on a project for protective covers for industrial sensors. Standard PMMA just wasn’t cutting it; a dropped tool or an accidental knock would crack them. We switched to an impact-modified grade, and the field failures dropped dramatically. The slightly higher material cost was nothing compared to the cost of replacements and downtime.

- Trade-offs? Sometimes, adding impact modifiers can slightly reduce the optical clarity or surface gloss compared to pristine standard PMMA, and it might lower the heat resistance a bit. But for many applications, the gain in toughness far outweighs these subtle differences.

- High-Heat PMMA:

- What is it? These are grades formulated to have a higher Heat Deflection Temperature (HDT) or Vicat softening point. This means they can withstand higher operating temperatures without deforming, warping, or losing their structural integrity.

- When to use it? Common applications include automotive interior components that bake in the sun, bezels or lenses for light fixtures (especially with hotter traditional bulbs or even high-power LEDs), appliance components near heating elements, or any part that operates in an elevated temperature environment. We did some light covers for an industrial oven viewing port once – standard PMMA would have turned into a puddle! A high-heat grade was absolutely essential.

- Considerations: The increase in heat resistance is significant, but it’s important to check the specific HDT value against your application’s maximum expected temperature, always with a safety margin.

So, is it worth the extra cost? If your product is failing in the field due to breakage or heat deformation, then absolutely. The cost of warranty claims, reputational damage, and redesigns will quickly eclipse the premium paid for a more robust material. It’s about designing for reliability from the outset.Conclusion

Selecting the right PMMA grade is key. Consider properties, additives, and special needs like optical, impact, or heat resistance. CavityMold helps you choose wisely for project success.