Choosing the right transparent material for your project can feel overwhelming. You need clarity and durability, but picking the wrong plastic can lead to cracked parts, budget overruns, and frustrating delays. Making the right choice from the start is critical for success, ensuring your final product performs exactly as you designed it.

The best clear plastic depends entirely on your application’s specific needs. For ultimate impact strength, choose Polycarbonate (PC). For the best optical clarity and scratch resistance, Acrylic (PMMA) is superior. For a versatile, chemical-resistant, and easy-to-fabricate option, PETG is an excellent all-rounder. Each material offers a unique balance of properties, cost, and processability that you must weigh carefully.

I’ve spent over a decade in the mold manufacturing business, and I’ve seen firsthand how material selection can make or break a project. A project manager, let’s call him Alex, might come to us with a design that’s perfect on paper, but the specified material just isn’t right for the real world. The key is to look beyond the spec sheet and understand how these plastics behave during molding and in their final environment. Let’s break down the most common head-to-head matchups to give you the clarity you need.

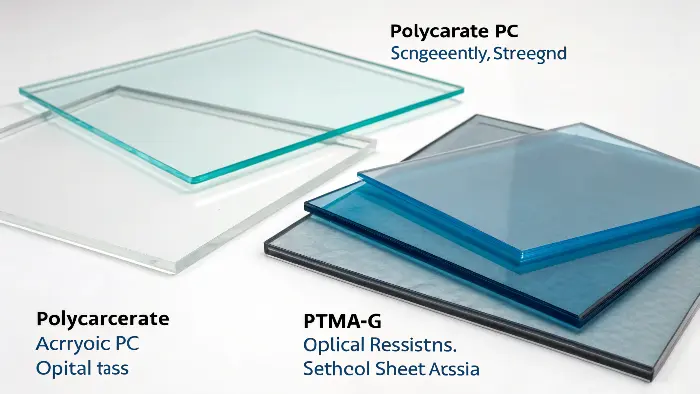

Is polycarbonate plastic better than acrylic?

You’re looking for a tough, crystal-clear material, but you’re stuck between Polycarbonate (PC) and Acrylic (PMMA). They both look great, but you know there are hidden differences. Choosing the wrong one could mean your product shatters on impact or gets hazy and scratched over time, forcing costly redesigns and damaging your reputation.

Polycarbonate (PC) is not inherently "better" than acrylic (PMMA), but it is significantly stronger and more impact-resistant. However, acrylic offers better optical clarity, superior UV resistance, and a harder surface that resists scratching more effectively. The "better" choice depends entirely on whether you prioritize toughness over optical perfection and surface hardness for your specific project.

When I talk to project managers, the PC vs. Acrylic debate comes up constantly. They are the two most common choices for clear, rigid parts. The decision almost always comes down to one question: How much abuse does this part need to take?

Impact Strength: The Clear Winner is PC

Polycarbonate is a beast. It’s the material used for riot shields, machine guards, and "bulletproof" glass. Its impact strength is legendary, around 250 times that of glass and about 30 times that of acrylic. If your part is going to be in a high-traffic area or is meant to protect something (or someone), PC is almost always the right answer. I remember a client who initially wanted to use acrylic for a set of machinery safety guards because it was slightly cheaper and looked great. I showed them a video of a hammer test on both materials. The acrylic shattered. The polycarbonate just bounced the hammer back. The decision was made instantly.

Clarity, Hardness, and Aesthetics: Acrylic’s Advantage

While PC is tough, acrylic is prettier. It has a higher light transmittance (around 92%) than PC (around 88%), making it optically clearer. It also has a harder surface, which makes it more resistant to scratches from everyday handling. This is why you see acrylic used for high-end retail displays, museum cases, and cosmetic packaging. It has a polished, glass-like appearance that PC can’t quite match. However, acrylic is more brittle. If you drop an acrylic box, it’s likely to chip or crack. A PC box would just scuff.

Here’s a simple breakdown:

| Feature | Polycarbonate (PC) | Acrylic (PMMA) |

|---|---|---|

| Impact Strength | Extremely High | Low / Brittle |

| Optical Clarity | Very Good (88%) | Excellent (92%) |

| Scratch Resistance | Fair (Scratches easily) | Good (Harder surface) |

| UV Resistance | Fair (Can yellow without coating) | Excellent |

| Fabrication | Easy to drill/cut without cracking | Can crack if not handled carefully |

| Cost | Higher | Lower |

For us at CavityMold, molding PC requires careful attention to drying the raw material, as moisture can cause major defects. Acrylic is a bit more straightforward to mold but requires careful part design to avoid stress concentrations that could lead to cracking.

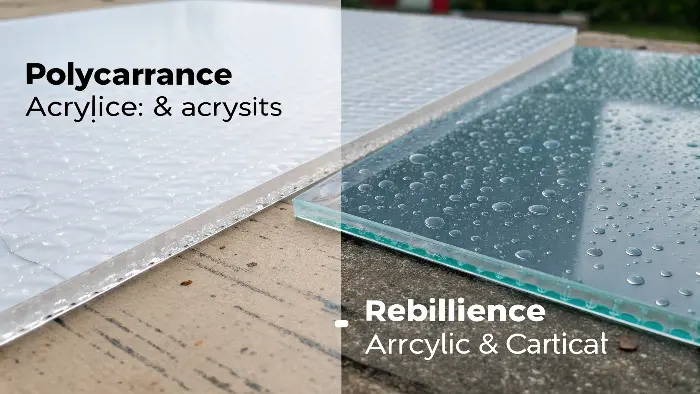

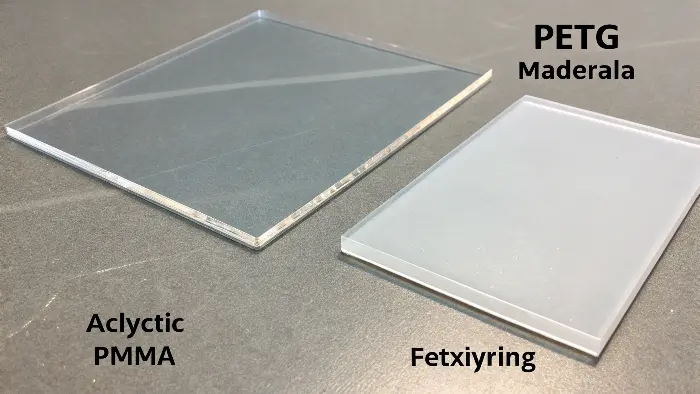

What is the difference between PMMA and PETG?

You’ve ruled out PC and are now deciding between Acrylic (PMMA) and PETG. They look similar, and their costs are in the same ballpark. This uncertainty can stall your project. Choosing incorrectly might lead to parts cracking during assembly, failing when exposed to cleaning chemicals, or not holding up to the rigors of shipping and handling.

The main difference between PMMA (Acrylic) and PETG is durability and chemical resistance. PETG is more flexible and significantly more impact-resistant than the rigid and brittle acrylic. PETG also offers superior chemical resistance, making it suitable for containers and medical devices. Acrylic, on the other hand, boasts better optical clarity, surface hardness, and UV stability.

Think of PETG as a practical workhorse and Acrylic as a polished showpiece. I often guide clients through this choice by asking about the product’s journey after it leaves the factory. Will it be bent, dropped, or cleaned with harsh chemicals?

Flexibility and Durability: PETG’s Domain

PETG is a member of the polyester family (like the plastic in water bottles) but modified for better durability. It’s much more flexible and forgiving than acrylic. You can bend a thin sheet of PETG, and it will flex back. Try that with acrylic, and it will snap. This makes PETG fantastic for parts that need some give, like snap-fit enclosures or packaging that gets handled roughly. Its impact strength isn’t as high as PC’s, but it’s far superior to acrylic’s, making it a great middle-ground option for durability.

Chemical Resistance and Food Safety

This is a huge differentiator. PETG stands up well to many common chemicals and cleaning agents that would cause acrylic to "craze" or develop tiny stress cracks. This is why PETG is so common in the medical field for device packaging and in retail for things like food containers. It’s generally FDA-compliant for food contact, which is a major advantage for many applications. Acrylic, by contrast, is not known for its chemical resistance.

Here’s how they stack up:

| Feature | PETG | Acrylic (PMMA) |

|---|---|---|

| Impact Strength | Good / High | Low / Brittle |

| Flexibility | High (Flexible) | Low (Rigid) |

| Chemical Resistance | Excellent | Poor |

| Optical Clarity | Very Good | Excellent (Slightly better) |

| Fabrication | Excellent (Easy to form/bond) | Good (Can be brittle) |

| Food Contact | Generally FDA-Compliant | Not typically used |

A project manager I worked with, Alex, was designing a new line of point-of-purchase displays. He was set on acrylic for its premium, glass-like look. But the design involved some tight bends and snap-on components. During prototyping, the acrylic parts kept cracking. We suggested a switch to PETG. He was worried about losing clarity, but the difference was barely noticeable. The PETG parts could be easily formed and assembled without any breakage, saving him a ton of time and scrap material.

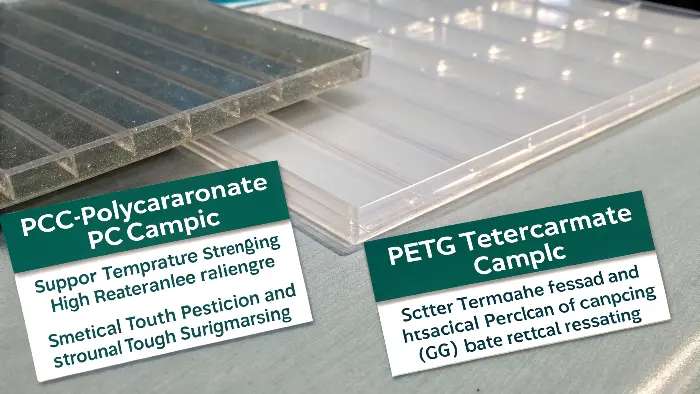

Is clear PC better than PETG?

You need a tough, clear plastic, and both Polycarbonate (PC) and PETG are strong contenders for the job. The choice isn’t obvious. One might be expensive overkill and blow your budget, while the other might not be quite tough enough for the application, leading to field failures and warranty claims down the line.

Polycarbonate (PC) is generally "better" than PETG in terms of pure impact strength and high-temperature resistance, making it ideal for the most demanding environments. However, PETG is more cost-effective, has better chemical resistance, and is much easier to fabricate and form. For many applications that don’t require PC’s ultimate toughness, PETG is a more practical and economical choice.

This comparison is all about matching the level of performance to the price tag. PC is the premium option for when failure is not an option. PETG is the smart, economical choice for a huge range of "tough-enough" applications.

When to Pay the Premium for PC

Polycarbonate’s key advantages are its incredible impact strength and its higher heat deflection temperature. It can withstand temperatures up to about 115°C (240°F) before it starts to soften, whereas PETG gets soft around 80°C (176°F). If your part will be used outdoors in a hot climate, house electronics that generate heat, or needs to withstand violent impacts, you need to specify PC. Think of things like helmet visors, industrial light covers, or housings for power tools.

The Practical Advantages of PETG

For a vast number of applications, PC’s strength is simply overkill. This is where PETG shines. It offers a fantastic balance of properties at a lower price point (often 15-25% less than PC). Its biggest advantage over PC is its superior chemical resistance. PC is susceptible to attack from certain oils, solvents, and cleaning agents, which can make it brittle. PETG holds up much better. Furthermore, PETG is much more forgiving to process. It can be thermoformed, molded, and bonded with less specialized equipment and expertise. It doesn’t require the intensive pre-drying that PC does, which simplifies the manufacturing process and can lower costs for us at CavityMold.

Here’s the final head-to-head:

| Feature | Polycarbonate (PC) | PETG |

|---|---|---|

| Impact Strength | Extreme | Good / High |

| Heat Resistance | High (up to 115°C) | Moderate (up to 80°C) |

| Chemical Resistance | Fair | Excellent |

| Cost | Higher | Lower |

| Ease of Fabrication | Good | Excellent |

| Scratch Resistance | Fair | Fair (Slightly worse than PC) |

I often see engineers default to PC for any part that needs to be "strong." But I always ask them to define "strong." For a recent project involving guards for a CNC machine, the client specified PC. We asked about the operating environment and learned that the guards were frequently exposed to cutting fluids. We recommended PETG, which not only had more than enough impact resistance to stop flying chips but also wouldn’t be damaged by the chemicals. The client got a better-performing part and saved nearly 20% on material costs.

Conclusion

There is no single "best" clear plastic. The right choice is a trade-off between performance, aesthetics, and cost. Polycarbonate is your champion for extreme toughness. Acrylic delivers unmatched clarity and a premium finish. PETG provides a fantastic, cost-effective balance of durability, chemical resistance, and ease of use. Understanding these core differences will empower you to make the right call.