How Can You Nail That High-Gloss Finish on Food-Grade Plastic Parts?

Getting that perfect, mirror-like gloss on food-grade parts is a massive headache, right? Parts come out looking dull or hazy, and it just screams "cheap."

Getting that perfect, mirror-like gloss on food-grade parts is a massive headache, right? Parts come out looking dull or hazy, and it just screams "cheap."

Ever struggled with TPU overmolding, where parts peel apart? It’s frustrating, wastes cash, and tanks your product’s rep. We’ll show you how we achieve solid,

Feeling a bit lost with TPU injection molding? It can seem tricky, and wrong turns mean wasted money. This guide simplifies it, from picking materials

Frustrated with TPU defects? Tiny parameter tweaks can make a huge difference. Get it right for flawless parts! Fine-tuning TPU injection molding involves meticulous control

Struggling with TPU? Choosing the wrong grade means poor performance. Get it right for top-quality parts. Selecting the right TPU hardness involves understanding your product’s

Struggling with acrylic injection molding? Getting cloudy parts, cracks, or inconsistent results? We’re here to shed some light on making it work, perfectly. Successful acrylic

Struggling with acrylic projects? Cracks, crazing, poor finishes? We’ve got solutions to turn your acrylic processing from a headache into a success story. Mastering acrylic

Think acrylic is old news? Stagnant? You’re missing out on game-changing innovations. New formulations are boosting performance and opening up exciting possibilities you haven’t even

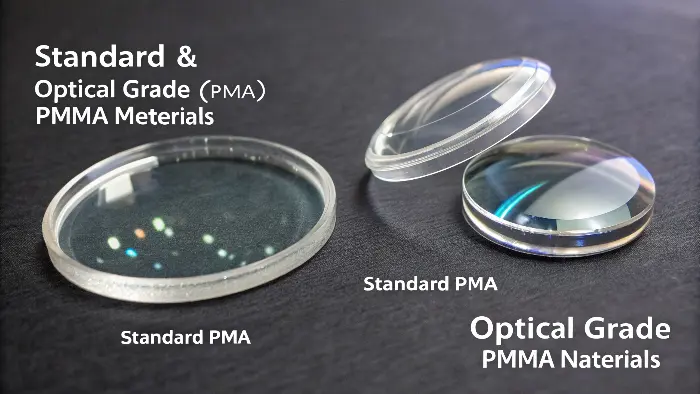

Choosing acrylic seems easy, but the wrong grade tanks your project. Costs rise, performance drops. We’ll guide you to the perfect PMMA, ensuring success every

Finding the right material is a headache, right? Acrylic offers amazing versatility. CavityMold helps you unlock its full potential for your specific industry needs. Acrylic

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

or email direct:jerry@cavitymold.com

We will contact you within 1 working day, please pay attention to the email with the suffix “@cavitymold.com”.

Or email direct:jerry@cavitymold.com