Are you struggling to get complex plastic parts made with the exactness your project demands? A small flaw can derail your entire production schedule, leading to costly delays and product failures that damage your reputation. Precision injection molding provides the consistency and quality you need to succeed.

Precision injection molding drives success by producing highly accurate, complex, and repeatable components for critical applications. Across industries like automotive, medical, and electronics, it ensures parts meet strict tolerances and performance standards. This reliability is key to creating high-quality, market-leading products that consumers can trust and depend on.

The theory is one thing, but seeing it in action is another. I’ve been in this industry for over a decade, and the versatility of precision molding still impresses me. It’s not just about making plastic parts; it’s about solving real engineering challenges that define a product’s success or failure. Let’s dive into some specific industries to see how this process makes a tangible difference every single day.

How Does The Automotive Industry Depend On Precision Molding For Safety and Performance?

The smallest part in a car can have the biggest impact on safety. When a component fails, the results can be catastrophic, leading to huge recalls. Precision molding ensures every part performs flawlessly, every time, protecting both brands and drivers.

The automotive industry depends on precision molding to manufacture critical components with extreme accuracy and durability. Parts like sensor housings, fuel system components, and interior safety features must withstand harsh environments. Precision molding delivers the consistency needed to meet these demanding safety and performance standards reliably.

The modern vehicle is a complex machine, and precision molding is a quiet, essential player. It’s not just about dashboards and door handles anymore. We’re talking about components deep inside the engine bay and integrated into advanced driver-assistance systems (ADAS). These parts have to endure constant vibration, extreme temperatures, and exposure to chemicals. There is absolutely no room for error.

I remember a project for a major automotive supplier. They came to us with a design for a small, complex gear that was part of a new electronic parking brake actuator. The gear needed to be incredibly strong to handle the torque, but also lightweight and dimensionally stable across a wide temperature range. The material we chose was a glass-filled nylon, known for its toughness.

Designing for a Demanding Environment

The real challenge was in the mold design. The gear had fine teeth that required perfect filling without any air traps or sink marks. We ran extensive mold flow simulations to predict how the plastic would behave. This allowed us to optimize the gate locations and design specialized cooling channels that would ensure uniform cooling. If one part of the gear cooled faster than another, it would warp, and the part would fail. The final mold was a high-precision, multi-cavity tool that produced thousands of identical gears, each one meeting the client’s strict quality requirements. This is where precision molding truly shines—in its ability to deliver perfect repeatability at scale.

| Automotive Component | Key Requirement | Common Materials |

|---|---|---|

| Engine Cover | Heat Resistance | Glass-Filled Nylon |

| Sensor Housing (ADAS) | Dimensional Stability | PBT, PPS |

| Interior Trim Clip | Flexibility & Strength | POM (Acetal), ABS |

| Fuel System Connector | Chemical Resistance | PA, PEEK |

What Makes Precision Molding So Critical For The Medical Device Industry?

In the medical field, there is zero room for error. A single imperfect part in a surgical tool or a diagnostic machine can directly impact a patient’s health and safety. The question isn’t just about quality; it’s about guaranteeing perfection.

Precision molding is critical for the medical industry because it produces sterile, biocompatible, and dimensionally perfect components. From disposable surgical tools to complex diagnostic equipment parts, the process ensures absolute reliability. This is essential for meeting strict FDA and ISO regulations and ensuring patient safety.

When we work with clients in the medical sector, the conversation is different. It revolves around concepts like biocompatibility, sterilization methods, and material traceability. Every single plastic resin pellet used must be accounted for and meet stringent medical-grade standards. Many of these projects involve micro-molding, where we create tiny components with features smaller than a human hair.

These parts are often used in single-use surgical instruments, drug delivery systems, and diagnostic cartridges. The precision required is on another level. For example, we worked on a project to produce a component for a new lab-on-a-chip diagnostic device. It required microfluidic channels molded into the surface that were only a few microns wide. The client needed to ensure that fluids could flow through these channels predictably every single time.

Cleanliness and Control Are Everything

The entire manufacturing process for this part had to be managed in our ISO 8 (Class 100,000) cleanroom. This prevents any airborne particles from contaminating the parts. The mold itself was a work of art, built with tolerances measured in single microns. We used electric injection molding machines for their superior control and repeatability. The project’s success depended on our ability to control every variable, from the moisture content of the plastic resin to the temperature of the mold steel. This level of control is what allows medical device companies to innovate with confidence, knowing their components are safe and effective.

| Medical Application | Key Requirement | Common Materials |

|---|---|---|

| Surgical Instruments | Sterilizability (Autoclave) | PEEK, Ultem (PEI) |

| Catheter Components | Biocompatibility, Flexibility | Medical-Grade PVC, PEBAX |

| Diagnostic Cartridges | Optical Clarity, Purity | Polycarbonate (PC), COP |

| Implantable Devices | Biocompatibility, Longevity | PEEK, Medical Silicone |

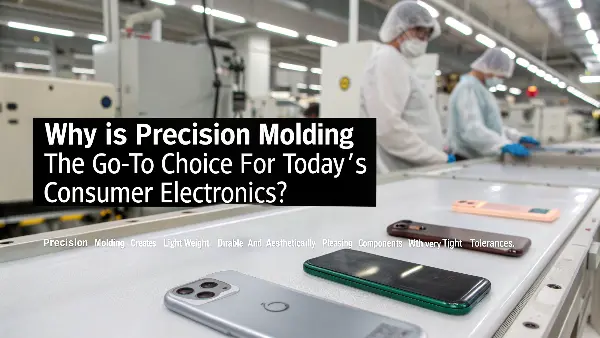

Why Is Precision Molding The Go-To Choice For Today’s Consumer Electronics?

Your new smartphone or wireless earbuds look sleek and feel solid, right? Achieving that perfect fit and seamless finish is one of the biggest challenges in consumer electronics manufacturing. One tiny gap or misaligned button can ruin the premium feel and user experience.

Precision molding is the top choice for consumer electronics because it creates lightweight, durable, and aesthetically pleasing components with very tight tolerances. It allows for complex designs like thin walls for casings and intricate snap-fits for assembly. This helps manufacturers produce high-quality devices at massive scale.

In the world of consumer electronics, appearance is just as important as function. Customers expect a flawless surface finish and parts that fit together perfectly. Precision molding is what makes this possible. We use it to create everything from the outer housings of smart speakers to the internal chassis of laptops and the tiny buttons on a remote control. Two key features that designers rely on are thin-wall molding and snap-fit assemblies.

Thin walls allow for devices that are lighter and more compact without sacrificing strength. Snap-fits allow for fast, screwless assembly, which creates a cleaner look and simplifies the manufacturing process. I remember a client who came to us with a design for a new smart home thermostat. They wanted a minimalist, seamless design with a high-gloss finish. The entire housing had to clip together with no visible fasteners.

Balancing Aesthetics and Function

The mold design was a real puzzle. The snap-fits had to be strong enough to hold the device together securely but flexible enough not to break during assembly. The gate location was also critical. A gate is where the molten plastic enters the mold cavity. If placed incorrectly, it can leave a visible mark on the final part, which was unacceptable for this product. We used advanced simulation software to test dozens of gate locations and injection parameters before we even cut the steel. We recommended a specific grade of PC/ABS for its excellent surface finish and impact strength. The final product was beautiful, strong, and exactly what the client envisioned.

| Part Feature | Design Goal | Molding Consideration |

|---|---|---|

| Thin-Wall Casing | Lighter, more compact device | High flow rate, proper venting |

| Snap-Fit Connectors | Screwless, fast assembly | Material flexibility, undercut design |

| High-Gloss Surface | Premium aesthetic look and feel | SPI-A1 polish on mold, clean material |

| Overmolded Grip | Soft touch, improved ergonomics | Two-shot molding, material bonding |

How Does Precision Molding Help Aerospace Components Meet Extreme Demands?

In an aircraft, every gram of weight matters, but so does strength and reliability. Aerospace components have to perform flawlessly under extreme conditions, from an icy cruising altitude to a hot tarmac. Failure is simply not an option.

Precision molding helps aerospace components meet extreme demands by using high-performance polymers to create parts that are strong, lightweight, and flame-retardant. It replaces heavier metal parts, improving fuel efficiency without sacrificing safety. The process ensures every component meets the strict quality standards of the aerospace industry.

The biggest trend in aerospace manufacturing is converting parts from metal to high-strength plastic. This is all about reducing weight to improve fuel efficiency. But you can’t just swap aluminum for any plastic. These materials have to be incredibly strong, resistant to jet fuel and hydraulic fluids, and flame-retardant to meet strict FAA regulations. This is where exotic, high-performance polymers like PEEK and Ultem come in.

These materials are difficult to mold. They require extremely high melt temperatures and specialized molding equipment. The molds also have to be built to withstand these conditions. We recently worked on a project to create an interior bracket for a private jet cabin. The original part was machined from a block of aluminum. Our task was to redesign it so it could be injection molded from a carbon-fiber-filled PEEK material.

Engineering for Flight

The goal was to cut the part’s weight by over 50% while maintaining the same or better strength. Our engineering team used finite element analysis (FEA) to simulate the stresses the bracket would experience in flight. This allowed us to add ribs and gussets to the design in key areas to add strength only where it was needed. The mold flow analysis was just as critical. The carbon fibers inside the plastic had to orient in the right direction during injection to provide maximum strength. The final molded part was a huge success. It was significantly lighter than the aluminum version but just as strong, and it passed every single one of the client’s rigorous tests. This is a perfect example of how precision molding is helping to build the next generation of aircraft.

| Aerospace Polymer | Key Property | Typical Application |

|---|---|---|

| PEEK | High Temp & Chemical Resistance | Bearings, seals, structural parts |

| Ultem (PEI) | Flame Retardant, Strength | Interior cabin parts, electrical connectors |

| Torlon (PAI) | Extreme Strength & Wear Resistance | Bushings, thrust washers |

| PPS | Dimensional Stability, Chemical Resist. | Fuel system components, pump housings |

Conclusion

From the engine of a car to a life-saving medical tool, precision injection molding is a core pillar of modern manufacturing. It delivers the accuracy, repeatability, and quality needed for success in the most demanding industries. Partnering with an expert mold maker ensures your vision becomes a reliable reality.