You’ve just opened a box of freshly molded parts, but your heart sinks. The surfaces are covered in wavy patterns and faint lines, making them look cheap and flawed. These flow lines are not just ugly; they can signal underlying weaknesses in the part. Now you have to figure out why it’s happening before you scrap the whole batch.

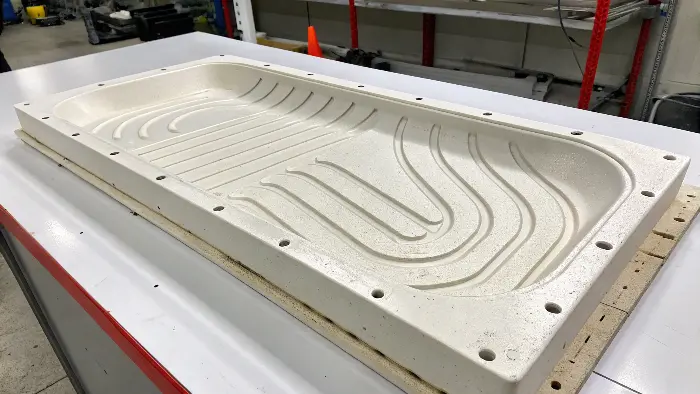

To prevent flow lines, you must ensure the plastic flows smoothly and evenly throughout the mold cavity before it cools. This is achieved by increasing the injection speed and pressure, raising the melt and mold temperatures, and optimizing the mold design. Key design changes include using larger gates and runners and ensuring uniform wall thickness to promote an even flow front.

These adjustments sound straightforward, but the real skill is in knowing which dial to turn and when. Over my years at CavityMold, I’ve seen how a small, targeted change can make all the difference. It’s about understanding the story the plastic is telling you through these defects. Let’s dive into the root causes of these flow marks and explore the specific, actionable steps you can take to eliminate them for good.

What is the root cause of flow marks in molding?

You see a distinct pattern on your part, a wavy or ring-shaped line that follows the path of the plastic flow. You know it’s a flow mark, but what is actually happening inside that steel mold to cause it? Without understanding the fundamental reason, any adjustments you make are just shots in the dark, potentially wasting time and material.

The root cause of flow marks is the premature cooling of the plastic as it flows through the mold. As the molten plastic touches the cooler mold walls, its viscosity increases rapidly. If the injection speed is too slow, different sections of the flow front cool at different rates, creating variations in speed and direction that get frozen onto the part’s surface as visible lines.

Think of it like pouring cold syrup onto a cold plate. It thickens up almost immediately and doesn’t spread smoothly, leaving thick, uneven trails. The same principle applies to plastic inside a mold. The key is to keep the plastic flowing like hot syrup until the entire cavity is filled. This requires a careful balance of temperature, speed, and pressure, all influenced by the design of the part and the mold itself.

The Physics of Flow

When molten plastic is injected into the mold, it travels through runners and gates into the cavity. The steel mold is significantly cooler than the plastic. The instant the plastic touches the mold surface, it begins to cool and solidify, forming a thin, frozen layer. The rest of the plastic flows through the center of this insulated channel. Flow marks appear when this process is not uniform.

Here are the primary factors that contribute to this problem:

| Factor Category | Specific Cause | How it Creates Flow Marks |

|---|---|---|

| Process | Low Injection Speed | Gives the plastic too much time to cool and thicken before the mold is full. The flow front hesitates and stutters. |

| Process | Low Melt/Mold Temperature | The plastic starts cooler or cools down too quickly upon contact, increasing its viscosity and impeding smooth flow. |

| Mold Design | Thin Walls or Sections | The plastic has to squeeze through a narrow space, increasing friction and causing it to cool and solidify too fast. |

| Mold Design | Sharp Corners | The flow path changes abruptly, causing turbulence and pressure drops that can lead to hesitation marks. |

| Material | Low-Flow Material | Some materials are naturally more viscous (thicker) and require more aggressive process settings to flow properly. |

A project manager I worked with, Alex, was struggling with flow lines on a large, flat housing. The part had very thin walls. His team tried increasing the injection speed, but it didn’t help. The root cause wasn’t just the process; it was the design. The walls were too thin for the distance the plastic had to travel. By identifying this, we worked with him to add a few flow channels on the non-cosmetic side of the part, which helped the material spread more evenly and eliminated the flow marks.

How do you control flow marks in injection molding?

You understand that flow marks are caused by the plastic cooling too quickly. Now, you need to translate that knowledge into action at the molding machine. With so many settings to adjust—temperature, pressure, speed—it can be overwhelming to know where to start. Making the wrong change could even introduce a new defect, like flash or burn marks.

To control flow marks, you must make targeted process adjustments. Start by increasing the injection speed to fill the mold before the plastic solidifies. If that’s not enough, increase the melt temperature and the mold temperature to lower the plastic’s viscosity. Finally, increasing the injection and packing pressure can help push the material smoothly into the final position.

I always advise my clients to follow a logical sequence. Start with the easiest and most impactful changes first. Speed and temperature are your primary tools for managing flow. Think of it as a balancing act: you need enough heat to keep the plastic fluid and enough speed to get it where it needs to go before it freezes. Let’s break down the specific adjustments and why they work.

A Hierarchy of Adjustments

When tackling flow marks, don’t change everything at once. Work through this list, making one adjustment at a time and observing the results.

1. Injection Speed and Pressure

This is often the most effective first step.

- Increase Injection Speed: A faster fill rate reduces the time the molten plastic spends traveling through the cold mold. This minimizes cooling before the mold is completely full, allowing the flow front to advance smoothly. Be careful not to go too fast, as this can cause other issues like jetting or burn marks if the mold is not properly vented.

- Increase Injection Pressure: Higher pressure provides the force needed to push the slightly thickening plastic through the cavity. It helps overcome resistance from thin sections or long flow paths.

2. Temperature Settings

If speed and pressure aren’t enough, it’s time to add more heat.

- Increase Melt Temperature: A hotter melt means lower viscosity. The plastic flows more easily, like water instead of honey. This is a very effective way to improve flow, but be mindful of the material’s degradation temperature.

- Increase Mold Temperature: A warmer mold surface slows down the rate at which the plastic solidifies upon contact. This keeps the flow channel open longer, promoting a smoother fill. This is especially critical for parts with long flow lengths or complex geometries.

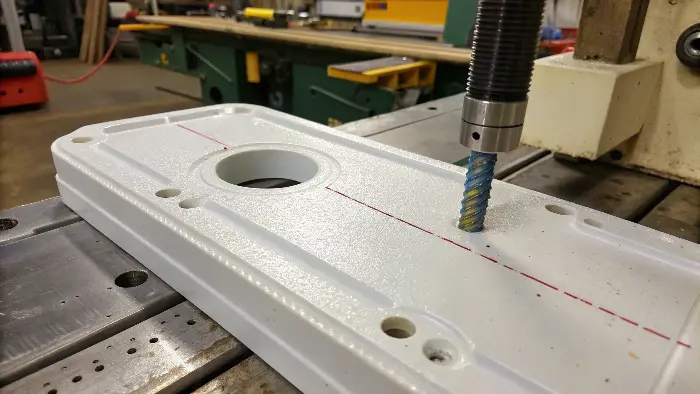

3. Mold Design Considerations

If process changes can’t solve the problem, the issue may be in the mold itself.

- Gate Size and Location: A small gate can restrict flow and cause the plastic to cool too quickly as it passes through. Enlarging the gate or changing its location to a thicker section of the part can dramatically improve flow.

- Runner System: Ensure the runners are large enough and not overly long to minimize pressure and heat loss before the plastic even reaches the cavity.

- Wall Thickness: As mentioned before, maintaining a uniform wall thickness is crucial. Avoid abrupt changes from thick to thin sections.

By methodically working through these solutions, you can systematically diagnose and eliminate flow marks from your production.

How do you avoid jetting in injection molding?

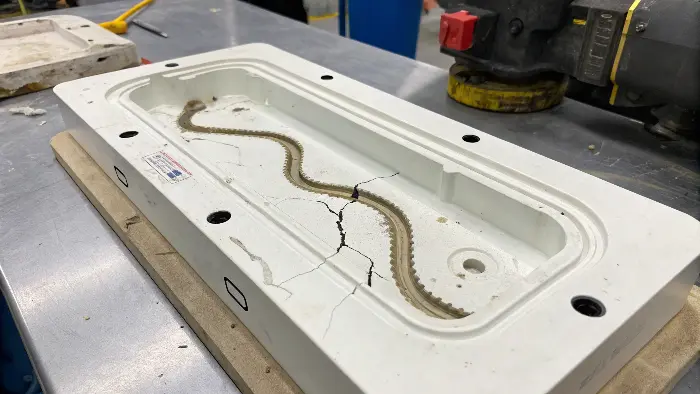

You inspect a part and see a snake-like or worm-like line starting from the gate and meandering across the surface. This defect, known as jetting, is not just a cosmetic flaw. It creates a weak, poorly bonded area within the part that can easily lead to failure under stress. It’s a clear sign that the plastic is entering the mold incorrectly.

To avoid jetting, you must control the initial flow of plastic as it enters the cavity. This is primarily a mold design issue. The gate should be positioned to direct the flow against a mold wall or a core pin. This forces the plastic to spread out in a fan-like pattern instead of shooting straight into the empty space. Using a tab or fan gate can also help diffuse the flow.

I once worked on a project for a consumer electronics device with a clear polycarbonate lens. Jetting was a complete showstopper because it was so visible. The initial design had a simple pin gate firing directly into the middle of the flat lens. The plastic shot across the cavity like a string before folding back on itself. The solution was a mold modification. We changed the gate to a "tab gate" on the edge of the part, which forced the plastic to enter with a wide, slow-moving front. The jetting disappeared completely.

Understanding the Cause of Jetting

Jetting occurs when the molten plastic is injected through a restrictive gate at high velocity into an open, unfilled section of the mold. Instead of the flow front gradually advancing and pressing against the mold walls, the stream of plastic shoots across the cavity. This "jet" of material then cools slightly before the rest of the plastic flows in around it, creating poor fusion between the jetted stream and the surrounding material.

Solutions for Jetting

Fixing jetting is about slowing down and redirecting that initial burst of material.

Mold Design Fixes (Most Effective)

- Gate Location: This is the number one solution. Reposition the gate so that the plastic stream immediately hits an obstruction, like the opposite wall of the cavity or a core pin. This "breaks up" the jet and forces it to start filling the mold with a progressive, uniform flow front.

- Gate Type: Change the style of the gate.

- Fan Gate: This type of gate widens at the entrance to the cavity, spreading the plastic out and reducing its velocity.

- Tab Gate: A small, secondary cavity (the tab) is placed next to the main cavity. The plastic fills the tab first, then flows slowly and broadly from the tab into the main part. The tab is trimmed off after molding.

Process Adjustments (Less Effective, but can help)

- Reduce Injection Speed: This is the most direct process change. By slowing down the initial fill rate, you can reduce the velocity of the plastic as it exits the gate. This is often a balancing act, as slowing it down too much can cause other flow marks. A profiled injection speed, where you start slow and then speed up, is an ideal solution.

- Increase Melt Temperature: A hotter, less viscous material is less likely to maintain a cohesive "jet" and will spread out more readily upon entering the cavity.

While process tweaks can sometimes minimize jetting, the most robust and permanent solution almost always involves a modification to the mold’s gate design.

How do you avoid weld lines in injection molding?

You’re examining a part with a hole in it, and you see a fine line on the surface on the side opposite the gate. This line, a weld line, is a common sight when the plastic flow has to split to get around an obstacle. The problem is that this line isn’t just cosmetic; it’s a potential point of failure where the part is structurally weaker.

To avoid weld lines, you need to ensure that the two separate flow fronts of plastic are hot enough to fuse together properly when they meet. This can be achieved by increasing the melt temperature, mold temperature, and injection speed. From a design perspective, repositioning the gate can move the weld line to a less critical, less visible area of the part.

Weld lines are a fact of life in any part that has holes or multiple gates. The plastic flow must divide to go around the core pin that forms the hole, and then it must recombine on the other side. The weld line is the seam where those two fronts meet. If they have cooled too much during their journey, they won’t intermingle and fuse perfectly, creating a weak bond. The goal is to make that seam as strong and invisible as possible.

Strengthening the Weld

The strength of a weld line depends on how well the two flow fronts merge. Think of it like trying to weld two pieces of metal; if they aren’t hot enough, you get a weak, brittle joint.

Strategies to Minimize or Move Weld Lines

You have two main approaches: improve the fusion at the weld line or change the design to move the weld line.

Process Improvements to Strengthen the Weld

These adjustments aim to keep the plastic hotter when the flow fronts meet.

| Adjustment | Action | Why It Works |

|---|---|---|

| Increase Melt Temperature | Raise the barrel temperature. | The flow fronts arrive at the meeting point hotter, allowing for better molecular entanglement and a stronger bond. |

| Increase Mold Temperature | Raise the temperature of the mold coolant. | Reduces the rate of cooling as the plastic flows, preserving heat in the flow fronts. |

| Increase Injection Speed | Fill the mold faster. | Gives the flow fronts less time to cool down before they meet. |

| Increase Packing Pressure | Raise the holding pressure after the fill. | Helps to force the two flow fronts together, improving the density and fusion at the seam. |

Mold Design Improvements

Sometimes, the best strategy is to accept that a weld line will exist and simply move it.

- Change Gate Location: This is the most powerful design tool. By changing where the plastic enters the part, you completely change the flow paths and, therefore, where the weld lines will form. You can often move a weld line from a high-stress, highly visible area to a low-stress, hidden area.

- Add an Overflow Tab: An overflow is a small, extra pocket added to the mold at the location where the weld line forms. The initial, cooler plastic from the very tip of the flow fronts flows into this tab, which is later trimmed off. This allows the hotter material behind it to form the actual weld line, resulting in a much stronger bond.

- Improve Venting: Trapped air at the point where weld lines form can prevent the flow fronts from meeting and fusing properly. Adding a vent at this location allows the trapped air to escape, leading to a better weld.

Conclusion

Preventing flow lines, jetting, and weld lines comes down to controlling how plastic flows and cools inside the mold. By mastering the interplay between temperature, speed, and pressure, you can solve most issues. For persistent problems, a well-thought-out mold design is the ultimate solution. This combined approach ensures you produce clean, strong, and reliable parts every time.