Ever felt a bit lost trying to figure out what exactly a PET preform injection mold is? It sounds super technical, and maybe you’re wondering if it’s something you really need to understand for your projects. Well, getting a grip on this can actually make a big difference in your manufacturing process, helping you master molding right.

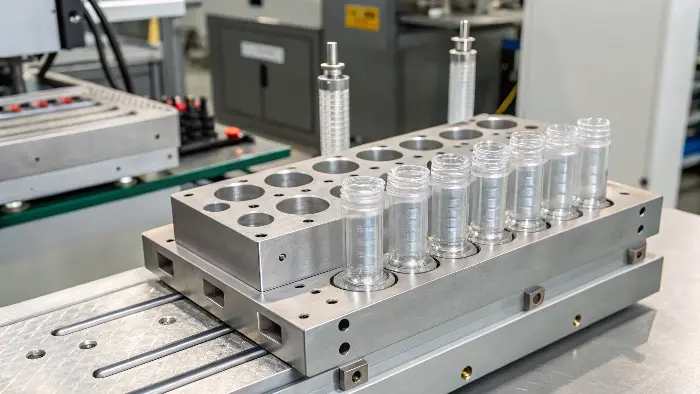

A PET preform injection mold is a specialized tool used to make PET (Polyethylene Terephthalate) preforms. These preforms look like test tubes and are the starting point for making plastic bottles and containers. The process involves melting PET resin, injecting it into the mold, and then cooling it to solidify the preform.

So, you’ve got the basic idea, right? But there’s a lot more to unpack here, and trust me, it’s pretty interesting stuff if you’re into how things are made. If you stick with me, we’ll dive deeper into what makes these molds tick and why they’re so crucial in the world of packaging. Let’s get into it!

What is PET in injection molding?

Heard the term PET thrown around in manufacturing discussions and felt a bit out of the loop? It’s a common material, but its specific role in injection molding might not be immediately obvious. Understanding PET is key to grasping why it’s chosen for so many applications, especially when you want quality.

PET, or Polyethylene Terephthalate, is a type of thermoplastic polymer. In injection molding, it’s prized for its strength, clarity, and recyclability. It’s melted down and injected into molds to create various products, especially packaging like bottles and containers, due to its excellent barrier properties against moisture and gases.

Okay, so PET is a big deal in plastics. But why this plastic? Well, let me tell you, as someone who’s seen countless materials go through our machines here at CavityMold, PET has some standout qualities that make it a go-to for many projects. It’s not just about picking any plastic; it’s about picking the right plastic.

So, what makes PET so special for injection molding?

First off, clarity and gloss. You know those crystal-clear water bottles you see everywhere? That’s PET! It gives products a really appealing, high-quality look, which is super important for consumer goods. If your product looks good, people are more likely to buy it. Simple as that.

Then there’s its strength and stiffness. PET is tough. It can handle the pressure of carbonated drinks, for example, and it’s not easily punctured. This means less breakage during shipping and handling, and more reliable packaging overall. I remember a project for a client, let’s call him Alex (he’s a project manager I work with often), who was developing a new sports drink. The bottle needed to be lightweight yet robust enough to withstand being tossed into a gym bag. PET was the obvious choice, and it performed brilliantly.

Another huge plus is its good barrier properties. This is a big one, especially for food and drinks. PET is great at keeping oxygen out and carbonation in. This helps maintain the product’s shelf life and quality, which is a major concern for any brand. Nobody wants their fizzy drink to go flat too soon, right?

And in today’s world, recyclability is massive. PET is one of the most recycled plastics globally, often labeled with the resin identification code #1. This makes it a more sustainable choice compared to some other plastics, and that’s something more and more companies, and consumers, are looking for.

Finally, from a manufacturing standpoint, its processability is excellent. It melts and flows well in injection molding machines, which is crucial for creating complex shapes and achieving consistent quality in the preforms. We’ve found it to be quite forgiving in the molding process, which helps us at CavityMold meet tight deadlines for clients like Alex, ensuring we master molding right, every time. So, when we talk about PET in injection molding, we’re talking about a versatile, reliable, and relatively eco-friendly material. It’s a real workhorse in the industry.

What is a preform mold?

You know about PET now, but what about the "preform mold" part? It sounds like something that comes before the final thing, and you’d be absolutely right! But understanding exactly what a preform mold does, and how it’s designed, is crucial if you’re involved in making bottles or containers. It’s not just any mold.

A preform mold is a specialized type of injection mold designed to produce "preforms." These preforms are an intermediate product, typically tube-shaped with a threaded neck finish, which will later be stretch blow molded into the final bottle or container shape. It’s the critical first step in a two-step manufacturing process.

Alright, let’s get a bit more specific about these preform molds. Think of it like this: you don’t just magically get a bottle. There’s a precise process, and the preform mold is a critical early stage where precision is everything. I’ve worked on designing and manufacturing these molds for years at CavityMold, and the engineering that goes into them is pretty intense. You’re aiming for perfection from the get-go.

So, what are the Key Characteristics of a Preform Mold?

First, they often have a multi-cavity design. To make production super efficient, these molds can have many cavities – I’m talking 32, 48, 72, sometimes up to 96 or even 144! This means one cycle of the injection molding machine can produce dozens of preforms. Imagine the output! This is essential for large-scale production.

Most modern preform molds use a hot runner system. This is a really neat bit of engineering. It keeps the plastic molten all the way from the machine nozzle to the individual cavities. The big advantage? It reduces waste because there are no sprues or runners (the channels for plastic flow in cold runner molds) to regrind. Plus, it improves cycle times and part consistency. Hot runner molds are more complex and a bit pricier to build, but the efficiency gains are massive, especially for high-volume parts like PET preforms.

Then there’s the neck finish precision. The neck part of the preform, where the cap will eventually go, has to be perfectly formed. The threads, the sealing surface – it all needs to be exact down to tiny tolerances. This part of the preform is fully formed in the injection mold and doesn’t change during the later blow molding stage. This is something Alex, our project manager friend, always emphasizes – the cap fit is absolutely non-negotiable for product integrity.

Efficient cooling system design is also vital. The faster the preforms can cool down and solidify properly, the shorter the cycle time. Shorter cycle times mean more preforms per hour, which means lower production costs. We spend a lot of time at CavityMold optimizing cooling channels in our mold designs to make sure they’re as efficient as possible.

And finally, the material these molds are made from. They are typically crafted from high-quality, hardened tool steels. This is to withstand the high pressures and temperatures of continuous injection molding and to ensure a long operational life – often millions of cycles. A good mold is an investment that pays off.

So, a preform mold isn’t just any old mold. It’s a high-precision, often high-cavitation, and very robust tool specifically engineered to produce the perfect starting point for billions of bottles and jars. It’s where the magic begins for a lot of the packaging we see and use every single day.

What is PET preform used for?

So we’ve got these PET preforms – these little plastic test-tube-like things with a threaded top. What’s the big deal? Why go to all the trouble of making them first, instead of just molding a bottle directly? Well, if you’ve ever wondered where all those plastic bottles come from, the answer starts right here with these preforms.

PET preforms are primarily used as the intermediate product for manufacturing PET bottles and containers through a process called stretch blow molding. They are heated and then stretched and blown into the final desired shape, like water bottles, soda bottles, jars for food, and containers for household products.

Okay, so these little guys are pretty important, huh? Absolutely! I’ve seen firsthand in my years at CavityMold how these preforms are the unsung heroes of the packaging world. We make the molds that make these preforms, and our clients then transform them into all sorts of useful things that line the shelves of supermarkets and stores. It’s quite a journey for such a small piece of plastic.

Let’s trace The Journey of a PET Preform:

- Creation (Injection Molding): First, as we’ve discussed, the PET resin is melted and injection molded into a preform using a specialized preform mold. This preform already has the finished neck and threads for the cap. The body is thick and compact.

- Heating (Reheating): The preform (importantly, except for the neck part, which needs to stay rigid) is then passed through an oven with infrared heaters. This heats it up to a precise temperature, making the PET soft and pliable, like taffy. Temperature control here is super critical for a good final bottle.

- Stretching and Blowing (Stretch Blow Molding): The heated preform is quickly transferred into a bottle-shaped mold (the blow mold). A steel rod (stretch rod) pushes down into the preform, stretching it vertically. Almost simultaneously, high-pressure air is blown into the preform, expanding it outwards like a balloon until it takes the shape of the blow mold. This biaxial stretching (stretching in two directions – axially and radially) is what gives PET bottles their amazing strength, clarity, and light weight.

So, where do you actually see the end products of these PET preforms? Here are some Common Applications:

- Beverage Bottles: This is the absolute biggest one. Think water bottles, carbonated soft drinks (CSDs), juices, sports drinks, iced tea, energy drinks – most of these come in PET bottles made from preforms. I remember a project with Alex where his company was launching a new line of organic juices. The exceptional clarity of PET was essential to showcase the natural, vibrant colors of the juice inside.

- Food Containers: Jars for peanut butter, mayonnaise, sauces, spices, salad dressings, and even some cooking oils often start as PET preforms. Its barrier properties help keep food fresh.

- Household Products: Bottles for liquid cleaners, detergents, dish soap, and personal care products like shampoos, conditioners, and lotions.

- Pharmaceuticals & Cosmetics: Some pill bottles, liquid medicine containers, and cosmetic packaging also utilize PET for its cleanliness and barrier properties.

The beauty of the preform system is its incredible efficiency, especially for logistics. Preforms are small, lightweight, and compact, making them much easier and cheaper to transport from the preform manufacturer to the bottling plant compared to shipping empty, bulky bottles. Then, at the bottling plant, they’re blown into full-size bottles right before filling. This saves a ton on shipping costs and warehouse space. It’s a really smart system, and it all starts with that precisely molded PET preform, made in a mold we at CavityMold could have built!

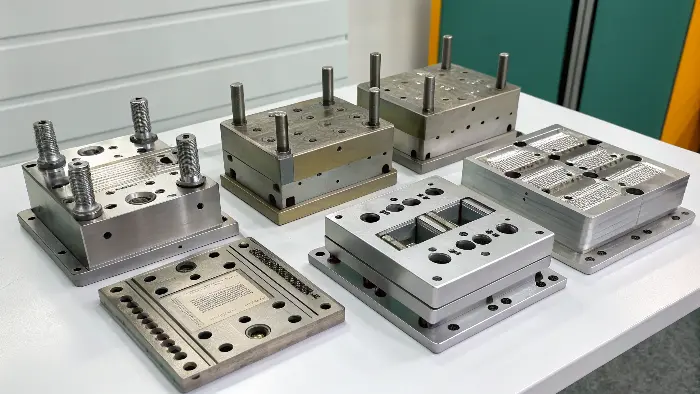

What are the different types of injection molds?

We’ve talked a lot about PET preform molds, which are a very specific and highly engineered type. But that’s just one slice of the pie, right? The world of injection molding is vast, and there are many different kinds of molds out there, each designed for different purposes. Feeling a bit overwhelmed by the variety? Don’t worry, let’s break down some common types to give you a broader picture.

Injection molds vary widely based on their design and function. Key types include two-plate molds (common and simpler), three-plate molds (for more complex gating), hot runner molds (for less waste and faster cycles), and cold runner molds (more traditional). There are also stack molds and family molds for specific production needs.

So, injection molds aren’t a one-size-fits-all kind of deal – not by a long shot. As an engineer at CavityMold, I’ve worked with a whole range of them, and choosing the right type is absolutely crucial for any project’s success, both in terms of part quality and cost-effectiveness. It’s like choosing the right tool for the job – you wouldn’t use a tiny screwdriver for a massive screw, would you? Let’s look at a few main categories.

First, let’s consider them Based on the Runner System:

- Cold Runner Molds: These are often simpler in construction and generally less expensive upfront. The "runner" is a channel machined into the mold plate that guides the molten plastic from the injection molding machine’s nozzle to the mold cavities. This runner solidifies with the part(s) and is ejected along with them. It then usually needs to be trimmed off (manually or automatically) and can often be reground and reused, but it’s still a source of waste and adds to cycle time.

- Pros: Lower initial mold cost, simpler design and maintenance.

- Cons: More material waste (the runner itself), potentially longer cycle times due to runner cooling and removal, and sometimes less consistent part quality if regrind is used extensively.

- Hot Runner Molds: These are more complex. They have a heated manifold system integrated into the mold that keeps the plastic molten all the way from the machine nozzle right to the gates of the cavities. So, no runner solidifies with the part!

- Pros: Significantly reduced or eliminated material waste (no runner), faster cycle times (no runner to cool), better part consistency, and more design freedom for gate location. This is what we typically use for high-volume PET preforms, as I mentioned.

- Cons: Higher initial mold cost, more complex design, and can be trickier to maintain.

Next, we can look at them Based on Plate Design:

- Two-Plate Molds: This is the most common and basic type of injection mold. The mold splits into two halves (the cavity side and the core side) at a single parting line. They are straightforward and effective for a huge variety of parts. The runner system (if cold runner) is on this parting line.

- Three-Plate Molds: These molds have an extra plate, creating two parting lines. This design is often used with cold runners when you need more flexible gating locations, like pin-point gates on the top surface of a part, away from the main parting line. The runner system is on a separate parting line from the parts, allowing it to be ejected separately.

And then there are some more Specialized Molds:

- Stack Molds: Imagine two or more mold parting surfaces (mold levels) stacked one on top of the other, all opening and closing together. This essentially doubles (or triples, etc.) the output from a single injection molding machine cycle without needing a much larger machine. They are great for high-volume production of relatively flat or shallow parts, like lids or shallow containers.

- Family Molds: These molds have cavities for different parts (but usually made of the same plastic material) all within a single mold base. This can be useful for producing all the plastic components of an assembly at once. For example, the front and back housing of a small electronic device. However, they can be tricky to design because you need to balance the filling of different sized and shaped cavities to ensure all parts mold correctly. Alex once brought us a challenge for a new electronic gadget that had three small, interconnected plastic pieces. A family mold was the solution, but it took some serious mold flow analysis and careful design to get it right and ensure all parts filled evenly and consistently.

So you see, the type of mold really depends heavily on the specific part design, the plastic material being used, the required production volume, part quality requirements, and, of course, the budget. It’s a key decision in the manufacturing process, and getting it right is part of what we mean at CavityMold by "Master Molding Right."

Conclusion

So, there you have it! From understanding what PET actually is, to how preform molds are engineered, what those little preforms are used for, and even a peek at other mold types. I hope this clears things up. A PET preform injection mold is a specialized, high-precision tool, absolutely vital for making the billions of bottles and containers we use every single day.