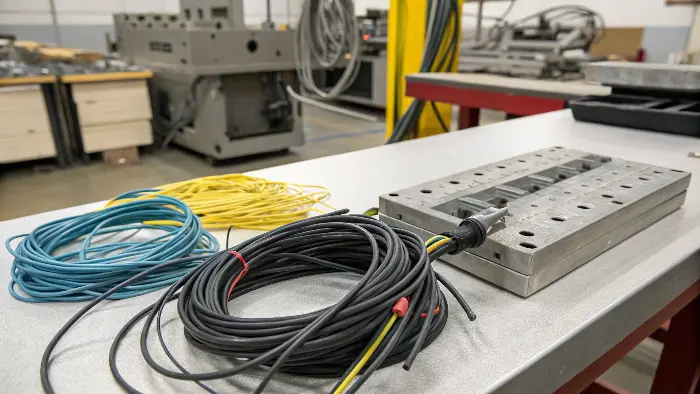

Tangled cables are a nightmare, right? It’s not just messy; it can be a real headache for safety and efficiency. You rely on cable ties to bring order, but have you ever stopped to think about the mold that makes these essential tools? A faulty mold means weak ties, and that’s a problem nobody wants.

Cable tie molds are typically crafted from high-grade tool steels like P20, H13, or S136. These are chosen for exceptional hardness, wear resistance, and thermal stability, crucial for precision molding of durable Nylon 66 cable ties.

It’s pretty clear that the mold material is super important for getting quality cable ties. But the story doesn’t end there. The material of the cable tie itself is just as critical. I think it’s worth looking at the whole picture, from the tie to the mold that shapes it. Let’s dig a bit deeper, shall we?

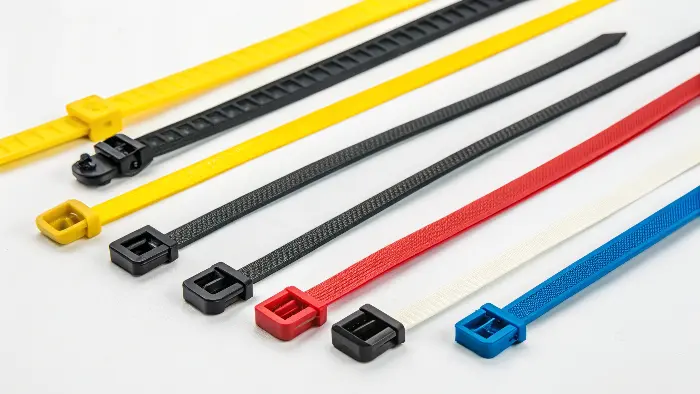

What material are cable ties made of?

Ever grabbed a cable tie and had it snap? It’s frustrating! Choosing the right cable tie often comes down to understanding what it’s made of. If the material isn’t up to snuff, you’re in for a bad time. So, what’s the secret ingredient for a reliable cable tie?

Cable ties are overwhelmingly made from Nylon 66. This thermoplastic polymer is selected for its excellent balance of strength, flexibility, durability, and resistance to environmental factors, making it ideal for securing cables effectively and reliably.

So, why Nylon 66? Well, I’ve been in this business for a while, and Nylon 66 is the go-to for a bunch of good reasons. First off, it’s strong. You need that good tensile strength to bundle cables tightly without the tie giving up. Think about it – those ties are often holding a fair bit of weight or tension. Then there’s flexibility. A cable tie needs to bend easily around whatever you’re securing, and the locking mechanism needs that slight give to engage properly. Nylon 66 nails this. It’s also pretty durable, standing up to general wear and tear.

One interesting thing about Nylon 66 is its relationship with moisture – it’s hygroscopic, meaning it absorbs water. This can actually affect its properties. That’s why manufacturers, including us at CavityMold, often use a "conditioning" process. This helps control the moisture content, ensuring the ties perform consistently. You might also see variations like heat-stabilized Nylon 66 for high-temp environments, or UV-stabilized versions for outdoor use where sun exposure is a concern. It’s all about tailoring the material to the job. And honestly, for most everyday applications, standard Nylon 66 is a fantastic, cost-effective choice. I remember a project where we helped a client select a UV-stabilized Nylon 66 for an outdoor installation, and it made all the difference in longevity.

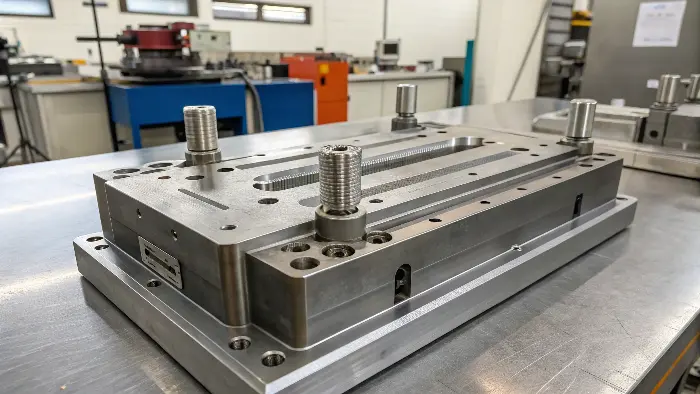

What material is used for cable molding?

We’ve talked about the cable tie itself, but what about the mold that makes it? If the mold isn’t top-notch, you can forget about getting consistent, high-quality ties. It’s like trying to bake a perfect cake in a dented pan – just won’t work out well.

Cable tie molds demand robust, high-precision tool steels. Common choices include P20, H13, or S136, selected for their hardness, wear resistance, polishability, and ability to endure repetitive high-pressure injection molding cycles.

When we at CavityMold design a cable tie mold, the material choice is critical. We’re talking about something that has to withstand a lot of stress. Think about it: molten plastic, usually Nylon 66, is injected under high pressure, cycle after cycle. So, the steel needs to be tough. We often use pre-hardened steels like P20 for many applications because it offers a good balance of machinability and durability. For molds that need to last even longer or produce ties with super fine details, we might go for through-hardened steels like H13. H13 is great for its high-temperature strength and excellent wear resistance – really a workhorse.

Then there’s S136, which is a stainless steel. This one’s fantastic if you need excellent corrosion resistance – maybe the molding environment is a bit humid, or the plastic itself has some mildly corrosive additives. Plus, S136 can be polished to a mirror finish, which is great for the surface quality of the cable ties and helps with part ejection. The key characteristics we look for are:

- Hardness: To resist wear and deformation. A must-have.

- Wear Resistance: For a long mold life, especially with filled nylons. You don’t want to be replacing molds too often.

- Toughness: To prevent cracking under pressure. Imagine the forces involved!

- Polishability: For smooth tie surfaces and easy ejection. Nobody wants sticky parts.

- Thermal Stability: To maintain dimensions at operating temperatures. Consistency is key.

It’s a precise science, and getting the mold material right is fundamental to producing millions of perfect cable ties. I recall one instance early in my career – not with CavityMold, thankfully! – where an inferior mold material led to premature wear, and the client ended up with out-of-spec ties. That was a costly mistake that really highlighted the importance of proper material selection from the get-go.

How can you describe cable ties?

"Cable tie" – sounds simple, right? But what exactly defines this little fastener? If you’re not careful, you might end up with something that looks like a cable tie but doesn’t perform like one. Knowing the key features is pretty important, I’d say.

Cable ties are self-locking fasteners, typically made of plastic (usually Nylon 66), designed for bundling cables or wires. They feature a flexible tape section with an integrated gear rack, and on one end, a pawl within a small open case forming a ratchet mechanism.

Okay, let’s break down what a cable tie really is. At its heart, it’s a one-piece fastener. You’ve got the tape section, which is the long, flexible part. This usually has a series of teeth or serrations on one side – that’s the gear rack. Then, at one end of this tape, you have the head. Inside the head is a clever little mechanism, usually a pawl, which is like a tiny, angled tongue. When you thread the pointy end of the tape through the head, the pawl engages with those teeth on the tape. It’s a ratchet system: it allows the tape to be pulled tighter, but it prevents it from slipping back out. That’s what gives it that secure, self-locking action. I’ve seen some pretty innovative designs over the years, but this basic principle is pretty universal for standard ties – it just works.

Their main job, of course, is to bundle and organize cables and wires. But people use them for all sorts of things! I’ve seen them used in gardening to support plants, for quick temporary repairs on camping gear, even in arts and crafts projects. They come in different types too: standard ones for general use, heavy-duty ones for bigger bundles or more strength, releasable ties that you can undo and reuse (super handy!), and even specialized ones like UV-resistant ties for outdoor use or colored ties for coding wires. The beauty of a well-made cable tie, like those from good Nylon 66, is its simplicity, strength, and ease of use. You just zip it, and it’s done. Fast and effective – what’s not to like?

What are the standards for cable ties?

How do you know if a cable tie is any good before you use it? You definitely don’t want it failing when it’s holding together a critical bundle of wires in, say, an server rack. This is where standards come in – they give us a baseline for quality and performance, which is a big deal.

Cable tie standards, such as those from UL (Underwriters Laboratories) or military specifications (e.g., SAE AS23190, which superseded MIL-S-23190), define criteria for tensile strength, material properties (like Nylon 66), flammability, temperature ratings, and dimensions, ensuring reliability and safety.

When we talk about quality cable ties, we’re not just guessing. There are actual standards that manufacturers should adhere to. These standards are super important because they ensure the ties you’re using are safe and will perform as expected. Think about it – if a cable tie fails in an electrical panel or in automotive wiring, the consequences could be serious. One of the big ones is tensile strength, often called loop tensile strength. This measures how much pulling force a locked cable tie can withstand before it breaks. It’s usually specified for different sizes or types of ties. For example, a standard 4-inch tie might have a lower tensile strength requirement than a heavy-duty 12-inch tie – makes sense, right?

Material specifications are also key. Standards often dictate the type of material, like Nylon 66, and may include requirements for things like UV resistance for outdoor ties (so they don’t degrade in sunlight and become brittle) or specific flammability ratings (very important for electronics and construction). Temperature ratings are another biggie – they’ll specify the operating temperature range the tie can handle, like up to 85°C (185°F) for standard Nylon 66, or even higher for heat-stabilized versions. I’ve seen projects where using the wrong temperature-rated tie led to them becoming brittle and failing prematurely – not a good look. Organizations like UL (Underwriters Laboratories) and bodies that manage military specifications (like the SAE AS23190) publish these standards. They cover:

| Standard Aspect | Description |

|---|---|

| Tensile Strength | Minimum force the locked tie must withstand. Crucial for holding power. |

| Material Type | E.g., Nylon 66, specific grade. Ensures consistency. |

| UV Resistance | For outdoor applications, ability to resist sunlight degradation. |

| Flammability | How it reacts to fire (e.g., UL94V-2 rating). Safety first! |

| Temperature Rating | Safe operating temperature range. Prevents failure in extreme conditions. |

| Dimensions | Tolerances for length, width, thickness. For proper fit and function. |

| Chemical Resistance | Performance when exposed to certain chemicals. Important in some industries. |

Meeting these standards means you’re getting a product that’s been tested and proven. It’s all about reliability and safety, and that’s something we take very seriously at CavityMold when producing the molds that make these essential ties. It’s not just about making a part; it’s about making a part that works, every time.

Conclusion

So, from the tough tool steel in the mold to the versatile Nylon 66 in the tie itself, every material choice matters a great deal. Getting these right means you get strong, reliable cable ties that meet important standards. It’s all about precision and quality, from start to finish – something we live by at CavityMold.