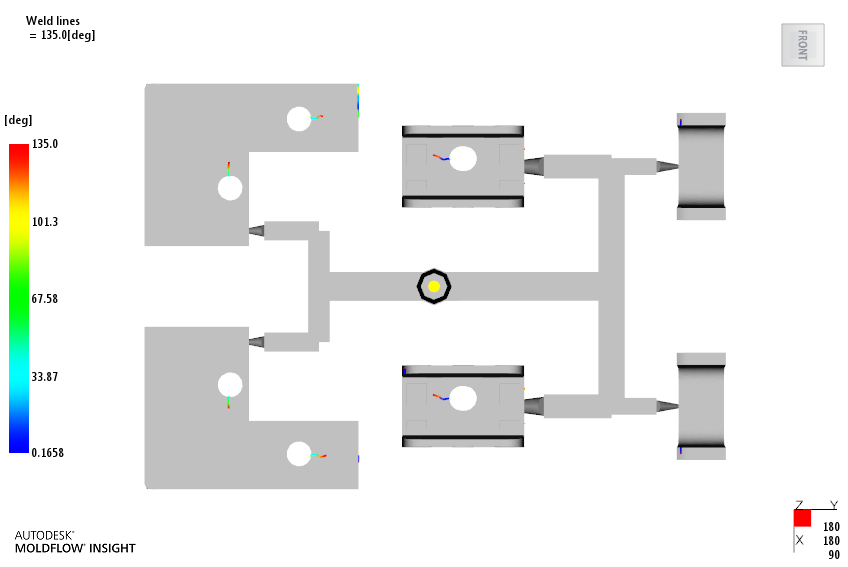

Preventing this is all about high-level design. I will discuss some molding defects that may occur in the injection molding process and how to repair and avoid them. Design defects we will discuss weld lines.

Explanation: in fact, the weld line is more like a plane than a line that meets each other as the molten plastic flows from two different parts of the mold.

Cause: When the molten plastic is partially solidified, it is caused by the insufficient combination of two or more flow fronts.

Remedial measures:

1. You can raise the temperature of the mold or molten plastic.

2. You can increase the injection speed.

3. The design of the flow pattern can be adjusted to a single source stream.

4. Change to plastic with less viscosity or with lower melting temperature.