Struggling to pick the right plastic for your part? Relying solely on mechanical properties from a datasheet can lead to costly manufacturing problems, compliance failures, and a product that just doesn’t meet expectations. It’s time to look at the bigger picture for true project success.

The best framework for selecting plastic materials goes beyond mechanical properties to include total cost, manufacturability, environmental impact, regulatory compliance, and aesthetics. Considering these factors early in the design stage ensures the material is not only strong enough but also cost-effective to process, safe for its intended use, and appealing to end-users.

I’ve seen many projects, managed by sharp engineers like Alex, hit a wall because the chosen material looked perfect on paper. The tensile strength was there, the temperature resistance was right, but it was a nightmare to mold. Or it didn’t meet a specific standard for a new market. This experience taught me that material selection is a strategic decision, not just a technical one. We need a framework that helps us think through all the variables. Let’s break down the key factors you need to consider beyond the basic datasheet to master your molding projects.

What’s the real cost of plastic material beyond the price per kilogram?

Tempted to choose the material with the lowest price per kilogram to keep your budget in check? This common approach can backfire, leading to unexpected expenses that inflate your total project cost. The real cost is much more than just the raw material price.

The true cost of a plastic material is its Total Cost of Ownership (TCO), which includes not only the purchase price but also processing costs, cycle times, scrap rates, and tool maintenance. A slightly more expensive resin that is easier to mold, has a lower scrap rate, and reduces cycle time often results in a lower cost per part.

When I was working with a client on a consumer electronics housing, they were initially set on a budget-friendly polycarbonate blend. The datasheet looked fine. But when we ran the mold flow analysis, the challenges became clear. This specific material required higher injection pressures and temperatures, which meant more energy consumption and more stress on the mold. We knew this would lead to a longer cycle time to ensure the parts cooled properly and avoided warpage. We presented a cost breakdown to Alex, the project manager.

Breaking Down the Total Cost

The price tag on a bag of resin is just the beginning. To get an accurate picture, you need to analyze several cost factors that emerge during production.

- Processing Costs: Does the material require high processing temperatures? This means higher energy bills. Does it need to be pre-dried? That adds time and equipment costs. A material that flows easily at lower temperatures can save a surprising amount of money over a long production run.

- Cycle Time: This is a major driver of part cost. A material that cools faster or fills the mold more quickly allows for more parts to be produced per hour. Even a few seconds saved per cycle adds up to significant savings and increased production capacity.

- Scrap Rate: Some materials are less forgiving than others. They might have a narrow processing window, leading to more rejected parts due to issues like sink marks, flash, or short shots. A material with a higher upfront cost but a wider processing window can easily pay for itself by minimizing waste.

Here’s a simple table to compare two materials beyond just their price:

| Factor | Material A (Low Cost) | Material B (Higher Cost) | Impact |

|---|---|---|---|

| Price per kg | $2.50 | $3.20 | Initial budget |

| Cycle Time | 45 seconds | 38 seconds | Higher throughput |

| Scrap Rate | 5% | 2% | Less waste, more usable parts |

| Tool Maintenance | Higher (abrasive) | Lower (less abrasive) | Reduced downtime and repair costs |

In the end, Alex agreed to use the slightly more expensive but more process-friendly material. The result was a lower final part cost and a much smoother production launch. This is the kind of strategic thinking that separates good projects from great ones.

Why is manufacturability a critical factor in material choice?

You’ve found a material with incredible strength and a great price. But what happens if you can’t mold it efficiently into your complex part geometry? This is where manufacturability becomes a make-or-break factor that is often overlooked in the early stages of design.

Manufacturability, or Design for Manufacturability (DFM), evaluates how easily a chosen material can be formed into the final part shape. It directly impacts production speed, part quality, and overall cost. A material that flows poorly, requires complex tooling, or has a narrow processing window can turn a great design into a production nightmare.

I remember a project for a medical device with several thin walls and intricate features. The original design team specified PEEK because of its superior strength and chemical resistance. However, PEEK is a high-temperature material with very high viscosity, making it extremely difficult to fill thin sections of a mold. The initial molding trials were a disaster, with constant short shots and immense stress on the mold. The project manager, Alex, was facing serious delays. We had to step in and work with them to find an alternative.

Key Aspects of Manufacturability

Thinking about how the material behaves in the mold is just as important as how the final part behaves in the field. Here are the core elements you must consider.

- Material Flow (Viscosity): How easily does the molten plastic flow? A material with good flow properties, like many ABS or Polypropylene grades, can easily fill complex geometries and thin walls. High-viscosity materials like PEEK or some polycarbonates require higher injection pressures and carefully designed gates and runners to fill the part completely.

- Shrinkage and Warpage: All plastics shrink as they cool. The key is how predictably and uniformly they do so. Materials with high, non-uniform shrinkage rates (especially fiber-filled ones) are prone to warpage, where the part twists out of shape. This requires complex mold design and process control to manage.

- Processing Window: This refers to the range of temperatures and pressures under which a material can be successfully molded. A material with a wide processing window is forgiving and easier to work with, resulting in more consistent part quality. A narrow window requires extremely precise control and can lead to higher scrap rates.

Here’s a comparison showing how material choice affects manufacturing considerations:

| Manufacturing Factor | Poor Material Choice (PEEK for thin wall) | Good Material Choice (High-Flow PC) |

|---|---|---|

| Mold Design | Requires complex, large gates and runners. High-pressure design. | Simpler mold design with standard gating is possible. |

| Processing | Very high melt temperature and injection pressure needed. | Moderate processing parameters, less energy intensive. |

| Potential Defects | High risk of short shots, voids, and weld lines. | Lower risk of flow-related defects. |

| Cycle Time | Longer due to injection and cooling requirements. | Shorter, more efficient cycle time. |

By switching to a medical-grade, high-flow polycarbonate, Alex’s team was able to solve their production issues. The part still met all the critical performance requirements but could now be molded reliably and cost-effectively.

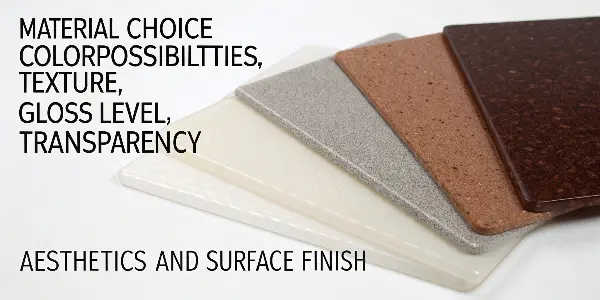

How do aesthetics and surface finish guide your material decision?

Your product can have perfect mechanical properties and be easy to manufacture, but if it doesn’t look and feel right to the customer, it may fail in the market. Aesthetics and surface finish are not just vanity metrics; they are essential to a product’s perceived quality and user experience.

Aesthetics and surface finish are crucial factors in material selection, especially for consumer-facing products. The material choice directly influences color possibilities, texture, gloss level, and transparency. Selecting a material that can achieve the desired look without secondary operations like painting or plating can significantly reduce costs and production complexity.

I worked with a startup designing a new line of high-end kitchen appliances. They wanted a sleek, high-gloss "piano black" finish. Their initial material choice was a standard grade of ABS. While ABS is a great all-around material, achieving that deep, flawless gloss directly from the mold can be challenging. It tends to show flow lines and can have a slightly muted finish. Alex, their project lead, was frustrated that the prototypes didn’t have the premium feel they were aiming for.

Matching the Material to the Desired Look

The visual and tactile properties of your product are determined by the interplay between the plastic material and the mold surface.

- Color and Appearance: Some materials are easier to color than others. For example, materials like ABS, PC, and PMMA can be compounded to achieve vibrant, consistent colors. For transparent parts, PC, PMMA (acrylic), and PETG are excellent choices, each offering different levels of clarity, impact resistance, and cost. If you need a metallic or pearlescent effect, special-grade resins with additives are available.

- Gloss and Texture: The final gloss of a part is a function of both the material and the mold’s surface finish. A highly polished mold (SPI-A1 finish) will produce a glossy part, but only if the material is capable of replicating that fine detail. Resins like ABS/PC blends and PMMA are great for high-gloss applications. Conversely, if you want a textured or matte finish, materials like TPE or glass-filled nylon can provide a tactile feel right out of the mold.

- Avoiding Surface Defects: The right material can help hide or prevent cosmetic flaws. For instance, sink marks are less visible on textured surfaces or with materials that have low shrinkage. Using a material with excellent flow properties can also minimize weld lines, which are visible lines where two plastic flows meet in the mold.

Here’s how material choices can impact the final look:

| Aesthetic Goal | Bad Material Choice | Good Material Choice | Why? |

|---|---|---|---|

| High-Gloss Finish | Glass-filled Nylon (GF-Nylon) | PC/ABS or PMMA | GF-Nylon fibers disrupt the surface, preventing a smooth, glossy finish. PC/ABS and PMMA have excellent surface replication. |

| Crystal-Clear Part | Polypropylene (PP) | Polycarbonate (PC) | Standard PP is naturally translucent or opaque. PC is amorphous and offers high clarity and impact strength. |

| Soft, Tactile Grip | Rigid ABS | Thermoplastic Elastomer (TPE) | ABS is hard. TPE is specifically designed for a soft, rubber-like feel and can be overmolded onto a rigid substrate. |

For the kitchen appliance project, we recommended a switch to a high-gloss grade of PC/ABS. It cost slightly more, but when molded in a highly polished tool, it delivered the deep, premium finish they wanted without any painting. Alex was thrilled, as it saved them the cost and headache of a secondary finishing process.

How do regulatory compliance and certifications limit your material options?

You’ve designed a fantastic product, but can you legally sell it in your target market? Regulatory compliance is a non-negotiable hurdle, and your choice of plastic is at the heart of it. Ignoring standards for safety, health, and the environment can lead to costly redesigns, product recalls, or being blocked from a market entirely.

Regulatory compliance dictates which plastic materials are permissible for specific applications, such as medical devices, food containers, or children’s toys. Standards like FDA, RoHS, REACH, and UL certification must be considered from the very beginning, as they significantly narrow down your material options and require certified resin grades.

One of my most memorable challenges was with a client developing an electronic toy for the European market. They had selected a cost-effective PVC compound for a flexible component. Everything was moving along until Alex, their an PM, realized late in the game that the material contained certain phthalates restricted under the EU’s REACH regulation. The project came to a screeching halt. We had to quickly source and test an alternative TPE material that was REACH-compliant, causing delays and budget overruns that could have been avoided.

Navigating the World of Standards

Compliance isn’t just a final checkbox; it’s a guiding principle that should shape your material selection process from day one. Different industries and regions have their own sets of rules.

- Food and Medical: For any part that will contact food or be used in a medical device, materials must meet strict biocompatibility and safety standards. In the US, this often means using FDA-compliant resins. In Europe, similar regulations apply. These materials are tested to ensure they don’t leach harmful chemicals.

- Electronics: Flammability is a major concern for electronic housings. The UL 94 standard is a common requirement, which rates a material’s ability to resist burning. Materials are rated from V-0 (burning stops within 10 seconds) to HB (slow burning). Using a pre-certified UL-rated material simplifies the product certification process.

- Environmental Regulations: Directives like RoHS (Restriction of Hazardous Substances) in Europe restrict the use of specific materials like lead, mercury, and certain flame retardants in electronics. REACH is even broader, covering chemicals used across all industries. Ensuring your material supplier can provide documentation for compliance is essential.

Here’s a quick guide to some common certifications and what they mean for your material choice:

| Certification | Industry | What It Governs | Material Implication |

|---|---|---|---|

| FDA | Food & Drug (US) | Materials safe for contact with food, drugs, and medical devices. | Must use specific grades of PP, PC, PET, etc., that have been certified as food-grade or biocompatible. |

| RoHS | Electronics (EU) | Restricts hazardous substances in electrical and electronic equipment. | Avoid materials containing lead, cadmium, certain flame retardants, etc. Must request RoHS-compliant resins. |

| UL 94 | Electronics, General | Flammability of plastics for parts in devices and appliances. | Must select a resin with the required flame rating (e.g., V-0, V-2, HB) for the specific application. |

| REACH | General (EU) | Registration, Evaluation, Authorisation and Restriction of Chemicals. | Requires that the materials used do not contain substances from the "Substances of Very High Concern" list. |

Since that toy project, I always make sure to ask Alex and other project managers about their target markets and required certifications on day one. Selecting a material that is already certified for your application saves an enormous amount of time, risk, and paperwork down the line. It’s a foundational step for a successful global product launch.

Conclusion

Choosing the right plastic is about more than just numbers on a datasheet. A strategic framework that considers total cost, manufacturability, aesthetics, and regulatory compliance is essential. This holistic approach ensures your final product is not only functional but also successful in the market, on time, and on budget.