Chasing those impossibly tight tolerances? When "close enough" means "complete failure" for your high-spec parts, the mold design itself becomes the make-or-break factor.

Achieving micron-level accuracy in injection molding hinges on meticulous mold design, considering material shrinkage, gate/runner optimization, cooling, venting, and robust tool construction.

You know, I’ve spent countless hours with designers like Jacky, poring over CAD models where every thousandth of an inch—heck, every few microns—matters. It’s intense! My core insight, and something we live by at CAVITYMOLD, is that mold design is absolutely paramount for achieving the required dimensional accuracy, especially when we’re talking micron-level. It’s not just about carving out a shape in steel; it’s about foreseeing and controlling a dozen interacting variables before the first chip is even cut. This involves a deep understanding of material selection (for the part), process parameters, and the machine’s capabilities, but it all comes back to how well that tool is conceived and built.

Transition Paragraph:

So, if you’re aiming for that "nth" degree of precision, just hoping for the best with a standard mold design approach won’t cut it. It’s like trying to perform microsurgery with a bread knife – just not gonna happen! We need to dig into the specific design considerations that elevate a mold from "good" to "precision-engineered." Let’s explore what really makes a difference when you need parts that are consistently perfect.

Which Parameters Should Be Considered While Designing the Mold?

Overwhelmed by all the details in mold design? Focusing on key parameters from the start can save you a world of hurt and ensure your parts meet spec.

Key mold design parameters include material shrinkage compensation, gate/runner design, cooling channel layout, venting adequacy, ejection method, and tool steel selection for stability.

Dive deeper Paragraph:

When I sit down to review a new precision mold design, or when Jacky sends over a challenging new part, my checklist is long! But some things are absolutely non-negotiable if we’re aiming for micron-level accuracy. My insight here is that mold design plays a crucial role in achieving the required dimensional accuracy. It’s not just one thing; it’s a symphony of well-thought-out features working together.

Here’s what’s always top of my mind:

### Material Shrinkage – The Big One!

This is probably the trickiest beast to tame in precision molding. Every plastic shrinks as it cools, and it doesn’t always shrink uniformly. My team and I spend a LOT of time on predicting and compensating for material shrinkage. We have to consider:- Material Type: Different polymers (ABS, PC, POM, PEEK, etc.) have vastly different shrinkage rates. Even different grades within the same polymer family can vary.

- Part Geometry: Thick sections shrink more than thin sections. Wall thickness variations are a nightmare for uniform shrinkage.

- Processing Conditions: Mold temperature, melt temperature, and packing pressure significantly influence shrinkage.

- Fiber Orientation: For fiber-filled materials, shrinkage will be different in the direction of flow versus transverse to flow.

So, the mold cavities are not cut to the exact final part dimensions. They’re cut slightly larger, based on calculated and experienced-based shrinkage allowances. Getting this right for a complex part aiming for micron accuracy? That’s art and science combined! I remember a medical device component, a tiny little thing, where we went through three iterations of shrinkage compensation on a test insert before we nailed it. Patience and data, that’s the key.

### Gate Design and Location:

How the molten plastic enters the cavity is critical. The gate influences:- Filling Pattern: We want a balanced, uniform fill to avoid weld lines in critical areas and to minimize stress.

- Shear Heat: Some gate types can generate excessive shear, potentially degrading the material.

- Cosmetics: The gate leaves a mark, so its location needs to consider the part’s aesthetic requirements.

- Packability: The gate must allow for effective packing pressure to compensate for shrinkage.

For precision parts, especially small ones, we often use pinpoint gates, submarine (tunnel) gates, or hot runner valve gates for precise control.

### Runner System Design:

For multi-cavity molds, the runner system must deliver melt to each cavity simultaneously and at the same pressure and temperature. A balanced runner system (geometrically or rheologically balanced) is essential for part-to-part consistency. We often use flow simulation software to optimize this. An imbalanced runner is a recipe for inconsistent parts, and you can kiss micron accuracy goodbye.### Cooling System Design:

I can’t stress this enough: uniform and efficient cooling is king for dimensional stability and minimizing warpage.- Channels must be strategically placed to cool all areas of the part as evenly as possible.

- We often use conformal cooling channels, which follow the contours of the part, for complex geometries. This can be a game-changer.

- Sometimes, we use high-conductivity inserts (like beryllium-copper, though we are careful with handling) in critical areas to pull heat out faster.

Uneven cooling means uneven shrinkage, which means a warped part. Simple as that.

### Venting:

Trapped air in the mold is bad news. It can cause short shots, burn marks, and poor surface finish. Adequate venting allows air to escape as the melt fills the cavity. Vents are tiny channels, usually at the parting line or on ejector pins, but their size and location are critical. Too small, and air gets trapped; too big, and you get flash.### Ejection System:

Getting the part out of the mold without distortion or damage is vital. Ejector pin size, number, and location must be carefully planned, especially for delicate or complex parts. We might use sleeve ejectors, stripper plates, or even robotic part removal for ultra-precision applications.### Mold Material and Construction:

The mold base and cavity/core inserts must be made from high-quality, stable tool steels. For high-volume precision molding, hardened steels are essential for wear resistance and maintaining dimensional integrity over millions of cycles. The overall construction must be robust to withstand clamping and injection pressures without deflection.

Thinking through these parameters right from the start—that’s how we lay the foundation for micron-level success. It’s a lot, but it’s what "Master Molding Right" is all about. 🔥What are the Critical Parameters for Injection Molding?

Feeling lost in a sea of machine settings? Knowing which parameters truly drive part quality can make or break your precision molding efforts.

Critical injection molding parameters include melt/mold temperatures, injection/packing pressures and speeds, and cooling time. These directly impact part dimensions, strength, and appearance.

Dive deeper Paragraph:

Okay, so we’ve designed an amazing, super-precise mold. But that’s only half the battle! Now we have to "drive" it correctly using the injection molding machine. My insight here is that even the best mold in the world can produce junk if the process parameters aren’t dialed in perfectly. And for precision molding, "perfectly" means a very, very narrow window. These parameters interact with each other, so it’s a delicate balancing act. This is where your operator’s skill and experience, along with the molding machine’s performance, really come into play.

Here are the big ones we obsess over:

### Temperatures (Melt and Mold):- Melt Temperature: This is the temperature of the plastic as it’s injected. Too hot, and the material can degrade, or shrinkage can be excessive. Too cold, and it might not fill the cavity properly (short shot) or create internal stresses. The material supplier gives a recommended range, but we often fine-tune it based on the specific part and mold.

- Mold Temperature: This is a HUGE one for precision. The temperature of the mold surface directly influences the cooling rate of the plastic, which in turn affects shrinkage, warpage, surface finish, and cycle time. For consistent precision parts, the mold temperature must be stable and uniform. This is where that excellent cooling system we designed into the mold proves its worth! I’ve seen projects saved simply by getting mold temperature control spot-on. We once had a part with a critical flatness tolerance that we just couldn’t hit. Turns out, one side of the mold was running a few degrees cooler than the other. Balanced the temps, and bingo – flat parts!

### Pressures (Injection, Packing/Holding):- Injection Pressure: The force used to push the molten plastic into the mold. It needs to be sufficient to fill the cavity quickly and completely.

- Packing/Holding Pressure: After the initial fill, pressure is maintained (or profiled) to pack more material into the cavity to compensate for shrinkage as the plastic cools. This is critical for achieving tight dimensional tolerances and minimizing sink marks or voids. The amount and duration of packing pressure are key adjustments for precision.

### Speeds (Injection Speed, Screw Recovery Speed):- Injection Speed: How fast the plastic is injected. This can affect surface finish, weld line strength, and whether the cavity fills properly. For some materials and part designs, a profiled injection speed (varying the speed during the shot) is necessary.

- Screw Recovery Speed: How fast the screw rotates to prepare the next shot. This can affect melt homogeneity and temperature.

### Times (Injection Time, Holding Time, Cooling Time):- Injection Time: Duration of the injection phase.

- Holding Time: Duration for which packing pressure is applied.

- Cooling Time: The time allowed for the part to solidify in the mold before ejection. This is often the largest component of the cycle time and is critical for dimensional stability. Rushing the cooling time to reduce cycle time is a common mistake that can kill precision.

It’s a complex dance. Changing one parameter can affect others. For example, increasing mold temperature might reduce sink marks but could increase cycle time and overall shrinkage. This is why scientific molding principles and systematic process development are so important, especially when Jacky needs parts that are perfect every single time.What are the Precision Injection Molding Tolerances?

Wondering just how "tight" can you get with injection molded plastics? The answer depends on several factors, but micron-level precision is achievable with the right approach.

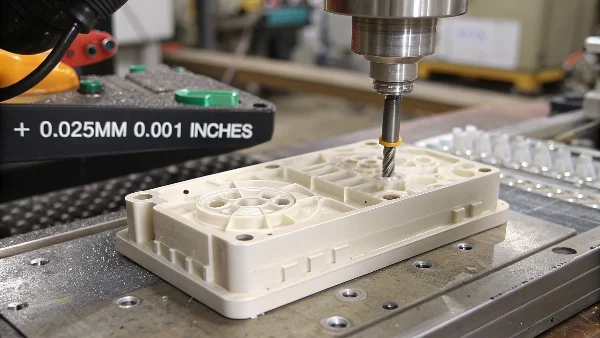

Precision injection molding tolerances can reach +/- 0.025mm (0.001 inches) or even tighter for small, well-designed parts, though material and complexity play significant roles.

Dive deeper Paragraph:

When Jacky comes to me with a new design for a tiny connector or a complex gear for some fancy new gadget, one of the first things we discuss is tolerances. Everyone wants the tightest tolerances possible, but "micron-level accuracy" isn’t a blanket guarantee for every part. My insight is that achievable tolerances are a function of part design, material choice, mold quality, and process control. It’s a system.

So, what can you realistically expect?

- General Purpose Molding: For less critical parts, tolerances might be in the +/- 0.005 to +/- 0.010 inches (+/- 0.125mm to +/- 0.25mm) range, or even looser. Think basic enclosures or toy parts.

- Precision Molding: This is where things get interesting. For well-designed parts made from stable materials, in a top-notch mold with a dialed-in process, we can often achieve:

- DIN ISO 2768: Many designers reference this standard. For plastics, common classes are ‘m’ (medium) or ‘f’ (fine). For very fine features, even tighter custom tolerances are specified.

- SPI Standards: The Society of the Plastics Industry (SPI) also has classifications.

- Typical Numbers: It’s not uncommon to see print tolerances of +/- 0.001 to +/- 0.002 inches (+/- 0.025mm to +/- 0.050mm) for critical dimensions on precision parts. For some micro-molding applications or very small features, we can sometimes even push into the +/- 0.0005 inches (+/- 0.012mm) range, which is truly getting down to the micron level (1 micron = 0.001mm).

Factors that influence achievable tolerances include:

### Part Size:It’s generally harder to hold tight tolerances on very large parts due to greater overall shrinkage.### Part Complexity:Complex geometries with varying wall thicknesses, ribs, and bosses can make uniform shrinkage difficult to achieve.### Material Selection:Some materials are inherently more stable and predictable in their shrinkage behavior (e.g., LCP, some PEEK grades) than others (e.g., unfilled Polypropylene or Nylon, which can absorb moisture and change dimensions). Material shrinkage characteristics are a massive factor.### Mold Quality:This is where our discussion on precision mold design comes full circle. You simply cannot achieve tight part tolerances with a sloppy mold. The mold itself must be built to even tighter tolerances than the part.### Process Control:Consistent machine performance and strict adherence to validated process parameters are key.

I always tell Jacky, "Let’s look at your critical-to-function dimensions. We’ll focus our tightest efforts there and see what’s realistically achievable for the rest." It’s about smart tolerancing, not just making everything unnecessarily tight, which drives up cost. But when micron-level is genuinely needed, that’s when our expertise in precision mold design and process control really shines. We’ve made parts where a 5-micron deviation was a reject – talk about pressure! 😅What Other Factors Can Be Expected to Contribute to the Part Quality During Injection Molding?

Think a great mold and a perfect process are all you need? Several other, sometimes overlooked, factors can significantly impact your final part quality.

Beyond mold/process, factors like material quality/preparation, machine maintenance, operator skill, and even ambient conditions can critically affect injection molded part quality.

Dive deeper Paragraph:

It’s easy to get tunnel vision and focus only on the mold and the machine settings, especially when you’re chasing micron-level precision. But as I’ve learned over the years—sometimes the hard way!—there’s a whole ecosystem of other factors that can make or break your part quality. My insight is that successful precision molding demands a holistic view; operator skill and experience, for example, can be just as critical as the molding machine’s performance.

Here are some other contributors that Jacky and I often discuss:

### Material Quality and Consistency:- Batch-to-Batch Variation: Is your resin supplier providing consistent material? Even minor variations in MFI (Melt Flow Index), filler content, or moisture content from one batch to another can throw off a finely tuned process. For critical jobs, we sometimes test incoming material.

- Regrind Usage: Using reground material can be cost-effective, but it must be done carefully. The percentage of regrind, its heat history, and its cleanliness can all affect part properties and dimensional stability. For ultra-precision, we often specify virgin material only.

### Material Preparation (Especially Drying!):

This is a HUGE one, especially for hygroscopic engineering plastics like Nylon, PC, PET, PBT. If these materials aren’t dried to the correct moisture content before molding, you’re asking for trouble. Splay marks, brittleness, dimensional instability – you name it. I can’t tell you how many "mysterious" molding problems I’ve seen solved by simply fixing the drying process. Invest in good dryers and use them correctly!### Molding Machine Maintenance and Calibration:

A high-precision machine is great, but if it’s not properly maintained and calibrated, its performance will degrade.- Wear and Tear: Check valves, screws, barrels, tie bars—they all wear out.

- Calibration: Are the temperature controllers, pressure sensors, and position sensors accurate? Regular calibration is essential. An uncalibrated machine might say it’s at 250°C, but if it’s actually at 260°C, your process is off.

### Environmental Conditions:

The temperature and humidity in the molding shop can sometimes play a role, especially with sensitive materials or very open-tolerance processes. Consistency is key. Also, think about dust and contaminants if you’re molding clear parts or medical devices.### Operator Skill and Experience:

This is invaluable. An experienced process technician can spot subtle signs of trouble, make intelligent adjustments, and understand the nuances of different materials and molds. They are not just button-pushers; they are craftsmen. This human element is crucial, especially when troubleshooting or setting up a new precision job. I really value my team’s expertise here; they often see things I might miss on a quick walk-through.### Post-Molding Handling:

How are parts handled after they come out of the mold? Are they dumped into a bin where they can warp or get scratched? For precision parts, careful handling, and sometimes even specific cooling fixtures, are necessary.

It’s a whole system. Attention to detail across all these areas contributes to that final, perfect, micron-accurate part that makes customers like Jacky happy. It’s a lot to manage, but that’s the commitment to quality we make at CAVITYMOLD.Conclusion

Achieving micron-level accuracy in injection molding is a journey of meticulous mold design, precise process control, and attention to every influencing factor. CAVITYMOLD masters these for you.