Struggling with the complexities of medical-grade plastics? A minor oversight in processing temperature can compromise an entire production run, leading to costly failures and regulatory headaches. Mastering these critical thermal parameters is not just best practice—it’s essential for ensuring patient safety and device efficacy.

Yes, overlooking temperature controls is a significant risk. The processing temperature for medical-grade plastics directly impacts their final properties, including structural integrity, chemical resistance, and, most importantly, biocompatibility. Materials like PEEK, PSU, and medical-grade Polycarbonate have very narrow processing windows. Deviating from these can cause material degradation, leaching of harmful substances, and failure to withstand sterilization, rendering the final product unsafe and non-compliant.

Temperature control is absolutely crucial, but it’s just one part of a much bigger picture. To truly get a handle on processing these sensitive materials, we need to start from the basics. Before we can even think about setting the molding machine’s parameters, we must first have a solid understanding of what makes a plastic suitable for medical use in the first place. It all begins with the material itself.

Let’s break down what "medical-grade" really means.

What Exactly Defines a Plastic as ‘Medical-Grade’?

Ever see the term "medical-grade" and wonder what it really entails? It sounds official, but the ambiguity can be risky. Choosing a plastic that doesn’t meet the strict requirements for medical applications can lead to catastrophic device failure, regulatory rejection, and potential harm to patients.

A medical-grade plastic is a polymer that has been specifically designed and tested for biocompatibility and safety in medical applications. This means it must be non-toxic, non-allergenic, and capable of maintaining its physical and chemical integrity after exposure to bodily fluids and sterilization processes. These materials, like medical PVC, PEEK, and silicone, are backed by extensive documentation and regulatory compliance data from bodies like the FDA and under standards like ISO 10993.

The "medical-grade" designation isn’t just a marketing label; it’s a promise of safety and reliability backed by rigorous testing and documentation. This goes far beyond the properties of a standard, off-the-shelf polymer. I remember a project early in my career where a client tried to substitute a standard polycarbonate for a medical-grade equivalent to save costs on a diagnostic device housing. The initial prototypes looked fine, but they failed spectacularly after the first round of gamma sterilization, becoming brittle and discolored. That experience taught me that the "grade" is non-negotiable.

The Foundation: Regulatory Compliance

The journey to becoming a medical-grade material is built on a foundation of strict regulatory oversight. The most recognized standard is ISO 10993, which outlines a series of tests to evaluate the biocompatibility of a material. This isn’t a single test but a comprehensive framework that assesses risks like cytotoxicity (is it toxic to cells?), sensitization (does it cause an allergic reaction?), and genotoxicity (does it damage genetic material?). The specific tests required depend on the device’s application—how it will contact the body and for how long. A surgical implant requires far more extensive testing than the casing of a handheld monitor.

Traceability and Consistency Are Key

Beyond initial testing, true medical-grade plastics require end-to-end traceability. This means the manufacturer must be able to track the material from the raw chemical constituents all the way to the final molded part. This is often managed through a Drug Master File (DMF) submitted to regulatory bodies like the FDA. The DMF contains confidential, detailed information about the chemistry, manufacturing, and testing of the resin. This ensures that every batch of plastic is identical and that no unapproved changes to the formula have been made. This level of control is what separates a true medical polymer from a standard industrial one.

Comparing Common Medical-Grade Plastics

Different applications call for different materials. Understanding their general characteristics is the first step in the selection process.

| Plastic Material | Key Characteristics | Common Medical Applications |

|---|---|---|

| Polycarbonate (PC) | High strength, transparency, heat and sterilization resistant | IV components, surgical instruments, renal dialysis units |

| PEEK | Excellent mechanical strength, chemically inert, radiolucent | Spinal implants, orthopedic fixation devices, dental posts |

| Medical PVC | Flexible, clear, low cost | Tubing, blood bags, IV bags, catheters |

| Polypropylene (PP) | Good chemical resistance, sterilization resistant, tough | Disposable syringes, medical packaging, sutures |

| Silicone | Highly biocompatible, flexible, wide temperature range | Catheters, tubing, seals, implantable devices |

What Are the Two Main Properties You Must Understand in Any Plastic?

When you’re starting a new project, it’s easy to get lost in a sea of technical data sheets. Focusing on the wrong properties can lead to poor material choices, causing production issues or field failures down the line. To avoid this, you need a clear starting point.

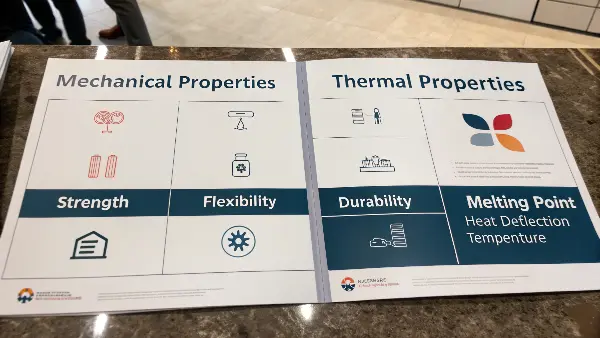

The two primary properties of any plastic are its mechanical and thermal characteristics. Mechanical properties define how the material behaves under physical stress—its strength, flexibility, and durability. Thermal properties dictate how it responds to heat during processing and its performance in its end-use environment, including its melting point and heat deflection temperature. These two categories govern almost every aspect of a plastic’s suitability for an application.

Grasping these two fundamental categories is like having a compass for navigating material selection. Everything else, from chemical resistance to optical clarity, often builds upon this foundation. I’ve seen projects get delayed simply because the team focused too much on a secondary property, like color, without first confirming the material could withstand the mechanical stresses and temperature requirements of the application. It’s a classic case of putting the cart before the horse. Let’s dig into what these two areas really mean for your project.

Diving Deep into Mechanical Properties

Mechanical properties tell us the story of how a plastic will perform physically. They answer critical questions: Will it bend or break? Can it withstand repeated stress? Is it hard enough to resist scratching? Key metrics here include:

- Tensile Strength: This measures the maximum stress a material can withstand while being pulled or stretched before breaking. It’s crucial for parts that will be under tension, like a hook or a strap.

- Flexural Modulus: This indicates the material’s stiffness or resistance to bending. A high flexural modulus means a rigid material (like PEEK for an implant), while a low modulus means a flexible one (like PVC for tubing).

- Impact Strength (Izod/Charpy): This is the material’s ability to absorb shock and sudden impact without fracturing. This is vital for handheld devices that might be dropped, like a glucose meter.

Understanding Thermal Properties

Thermal properties are equally important, especially in the context of this article. They define not only how we process the material but also where it can be used. Key thermal metrics include:

- Melting Temperature (Tm): For semi-crystalline plastics, this is the point where the material transitions from a solid to a viscous liquid. For amorphous plastics, we look at the a Glass Transition Temperature (Tg), where it goes from a rigid, glassy state to a rubbery one. These are the most critical parameters for injection molding.

- Heat Deflection Temperature (HDT): This tells us the temperature at which a plastic sample will deform under a specific load. It’s a practical measure of a part’s ability to maintain its shape at elevated service temperatures or during heat sterilization (like autoclaving). If a device needs to be sterilized at 134°C, its HDT must be significantly higher.

Getting both of these right ensures the part can be manufactured correctly and will perform reliably throughout its entire lifecycle.

Is Thermoplastic Biocompatible?

You’ve identified a thermoplastic that meets your mechanical and thermal needs, but a critical question remains. Can this material actually be used inside or in contact with the human body? The assumption that all high-performance plastics are safe for medical use is a dangerous one.

Yes, many thermoplastics are biocompatible, but this property is not inherent to the material type itself. Biocompatibility is achieved through specific medical-grade formulations that are rigorously tested according to standards like ISO 10993. Materials like PEEK, medical-grade polycarbonate, and polyethylene are excellent examples of thermoplastics that have proven biocompatibility. However, a standard industrial-grade version of the same polymer is not considered biocompatible due to different additives, processing aids, and lack of testing.

The distinction between a "thermoplastic" and a "biocompatible thermoplastic" is one of the most important lessons in medical device manufacturing. I work with project managers like Alex all the time, and one of the first things we clarify is this exact point. You can’t just select "polycarbonate" from a catalog; you have to select a specific grade, like Makrolon® Rx1805, that comes with the necessary certifications and biocompatibility data. The difference lies in the details—what’s added, what’s left out, and the proof to back it up.

The Role of Additives and Processing Aids

Standard industrial thermoplastics often contain a variety of additives to enhance certain properties—UV stabilizers, flame retardants, colorants, or mold release agents. While these are beneficial for commercial products, they can be toxic or cause adverse reactions in a medical context. Medical-grade formulations are developed with a "less is more" philosophy. They use only a minimal set of additives that have themselves been proven safe for biological contact. Any colorants used, for example, must be from an FDA-approved list, and the supplier must guarantee that no unapproved substances were introduced during polymerization or compounding.

The Importance of Leaching and Extractables Testing

A key component of biocompatibility testing involves evaluating leachables and extractables.

- Extractables: These are chemical compounds that can be "extracted" from the plastic under harsh laboratory conditions (e.g., strong solvents, high temperatures). This testing helps identify all potential substances that could migrate out of the material.

- Leachables: These are compounds that actually migrate from the plastic into the product under normal conditions of use. This is a more direct measure of what a patient might be exposed to.

For a thermoplastic to be deemed biocompatible, the levels of any leachables must be well below toxicological safety thresholds. This is a primary reason why temperature control during processing is so vital—overheating the plastic can cause material degradation, creating new, potentially harmful leachables that were not present in the original resin.

Biocompatibility is Application-Specific

Finally, it’s important to remember that biocompatibility is not a one-size-fits-all property. A material that is perfectly safe for transient skin contact might not be suitable for a long-term blood-contacting implant. ISO 10993 categorizes devices based on the nature and duration of body contact, requiring more stringent testing for higher-risk applications. Therefore, when someone asks if a thermoplastic is biocompatible, the correct follow-up question is always: "For what specific application?"

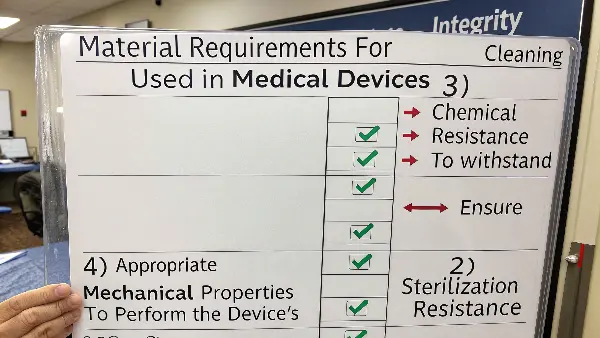

What Are the 4 Material Requirements for Plastics Used in Medical Devices?

So, we know what medical-grade means, we understand the core properties, and we’ve confirmed biocompatibility is essential. How do we tie this all together into a practical checklist? When selecting a material, you need a clear framework to ensure you haven’t missed anything critical.

The four essential requirements for plastics in medical devices are: 1) Biocompatibility to ensure patient safety, 2) Sterilization Resistance to maintain integrity after cleaning, 3) Chemical Resistance to withstand bodily fluids and disinfectants, and 4) appropriate Mechanical Properties to perform the device’s function reliably. Neglecting any one of these can lead to device failure. These must be evaluated in the context of the device’s specific use case and lifecycle.

I treat these four pillars as the ultimate go/no-go criteria for any medical device project. It’s a simple but powerful framework that prevents us from getting sidetracked. I once consulted on a project for a reusable surgical tool where the team had selected a material with fantastic mechanical strength. However, they overlooked its poor resistance to the hospital’s standard autoclave sterilization protocol. The handles started showing micro-cracks after just a few cycles, rendering the expensive tool useless. A quick check against these four pillars would have caught that flaw at the very beginning.

Pillar 1: Biocompatibility

As we’ve discussed, this is the non-negotiable starting point. The material must not harm the patient. This is confirmed through ISO 10993 testing data provided by the resin manufacturer for the specific medical grade you are using. You must match the level of testing to your device’s classification—whether it’s surface contact, short-term implant, or permanent implant. Always demand the documentation.

Pillar 2: Sterilization Resistance

Most medical devices must be sterilized before use. The chosen plastic must be able to withstand the chosen sterilization method without degrading. The common methods each pose unique challenges:

- Autoclave (Steam): Involves high heat (121-134°C) and moisture. Materials like PEEK, PSU, and some grades of PP and PC handle this well.

- Ethylene Oxide (EtO): A low-temperature gas process, gentler on materials but requires aeration to remove residual gas. Suitable for many plastics, including PVC and PE.

- Gamma Irradiation: Uses high-energy radiation to kill microbes. It can cause some plastics, like standard PP and PC, to become brittle or discolored. Specific gamma-stable grades are required.

Pillar 3: Chemical Resistance

The material must remain stable when exposed to substances it will encounter during its life. This includes bodily fluids (blood, lipids), aggressive cleaning agents, and disinfectants used in hospitals (like alcohols or peroxide-based solutions). Poor chemical resistance can lead to environmental stress cracking (ESC), where the plastic fails prematurely under load when exposed to a chemical.

Pillar 4: Mechanical Properties

Finally, the plastic must be able to do its job. It needs the right balance of strength, stiffness, toughness, and durability for the application. A part for a surgical robot needs extreme rigidity (high flexural modulus), while a catheter needs to be soft and flexible (low modulus). These properties must also be maintained after sterilization and aging.

Conclusion

Mastering medical-grade plastic processing comes down to respecting the material. From ensuring biocompatibility to resisting sterilization and meeting mechanical demands, every choice matters. Above all, precise temperature control during manufacturing is the critical link that protects these properties and ensures the final device is both safe and effective.