When searching for mold manufacturers, it is important to understand the market dynamics. You can find different categories of mold manufacturers. Some got funded by foreign investors or Taiwanese investors. They could also be Hong Kong-owned businesses or from other regions in China. In most cases, you want a mold that is custom made for your specific product. So there isn’t the option of picking a ready-made mold off the shelf. Neither can you click on a website and see mold prices listed. You will find some websites offering ready-made mold from mold makers in China. But these are for specific designs that limit the use. A mold is a very important investment for injection molded products. Whether you are making one for prototypes, short or long runs, the mold forms the identity of your product. It is the one part of your injection molding machine that needs a personal touch. In choosing a mold manufacturer, you want the best quality your budget can fetch. China in recent years has been the destination for many business enterprises. It is playing an active part in the new industrial age and a hub for business and manufacturing. In this article, we will discuss how to go about finding the best mold manufacturer in China. One that is best suited for your business and product. We will look at important factors in ensuring you get the mold maker that best matches your needs.

How to search for mold makers

Everything begins with a google search these days. When you have an idea or a question, the first thing many of us do is to ask google. This works to some extent. To get the most out of the time you spend searching google you can do a couple of things. First, ensure that the search term you enter into google will give you useful results. So you should use a search term that narrows it down a bit. For example “mold makers” will return anything that has mold makers in it. These might not even take you to injection molding or even mold maker websites. If you try “Mold makers in China” that narrows it down to anything relating to mold makers in China. These might be useful as they can take you to discussion forums and websites. These might have useful information about mold makers in China. But Google or the internet, in general, can sometimes be a rabbit hole. You can spend hours clicking on yes very interesting information. But they do not exactly answer your original question. You can search for terms that will only exist on the websites of mold manufacturers. For example “we are a professional injection cavity mold maker”. This will take you to sites of professional mold makers. You can further adjust the search terms to get more results that meet your specific needs.

The company website is the first point of contact for most modern companies. This is where you get a glimpse into the services they offer and their focus. From there you will also find their contact details. You can send an email or request a quote for the service you need.

Word of mouth still works. Speaking to people who have experience in injection molding gives a good lead. They can either recommend their mold maker or have practical advice on how to find one. So don’t hesitate to leverage the experience and knowledge of your network. You can find information on mold makers in forums and online communities.

A mold maker that has your time

You can compare this to going into a large chain supermarket vs going into a small corner shop. The large supermarket gets thousands of customers every week, maybe even every day. You can spend over a thousand dollars on a visit and the store manager would never even know you were there. The salesperson wouldn’t even bat an eyelid. But spend 10 dollars at a corner store and even the owner knows your name. This comes to play when deciding who to go to for your mold making service. You may want a company that will value you as an individual business. They would offer personalized service. Even if it’s a single mold you need, they’ll take the same time as they would a customer requesting many molds. A small to medium scale mold manufacturer has less volume of orders. They are keener on creating exceptional value for a handful of customers. They care more about gaining trust than quantity. More important is that there is a shorter chain of command. You are able to speak with the engineers who know more about injection molding. This compared to a large company where you are not likely to speak to anyone other than the salesperson. This is more so if you don’t have a large number of orders. Working with a large company does not always mean you are getting better value for your money. Or that it will get delivered faster. But large companies do have the advantage of reputation. They have a large customer base and a longer track record. This way you have some evidence that they can build molds. This of course means they have the basis for charging higher fees.

But a small or medium-sized mold maker might have a similar track record and years of experience. But only on a smaller scale. You would still be working with mold makers who have been making molds for over a decade. They may charge the same or higher as the larger companies. The reasoning behind charging the same is that they have less capacity to scale up. They still use the same tools with the same efficiency. So the key point here is that the size of the company is not an absolute sign of the quality of the mold you’ll get. But you are more likely to get more personalized service from the smaller companies. Many manufacturers today are following the trend of working with SME mold makers.

One way to know if a mold maker would dedicate good time to your work is to assess how they respond to inquiries. Of course, this also depends on how you contact them. In any case, getting a response within a reasonable time is indicative. Also who you get a response from does count. You should be able to get in touch with someone who has knowledge of injection molding.

What type of mold you Need

Prototype, short runs or long runs?. When searching for a mold maker you should show the type of mold you need. Some mold manufacturers might only specialize in a particular type of mold. For example, if you need a mold for prototype production. The materials and process requirements are different for molds for production. Molds that get used for long runs have different requirements from those used for short runs. Check if the supplier states a preference for a specific type of mold. There are many mold makers who deal with a wide range of mold types. So it is more common that your mold maker makes molds for all injection molding types.

Service Offering

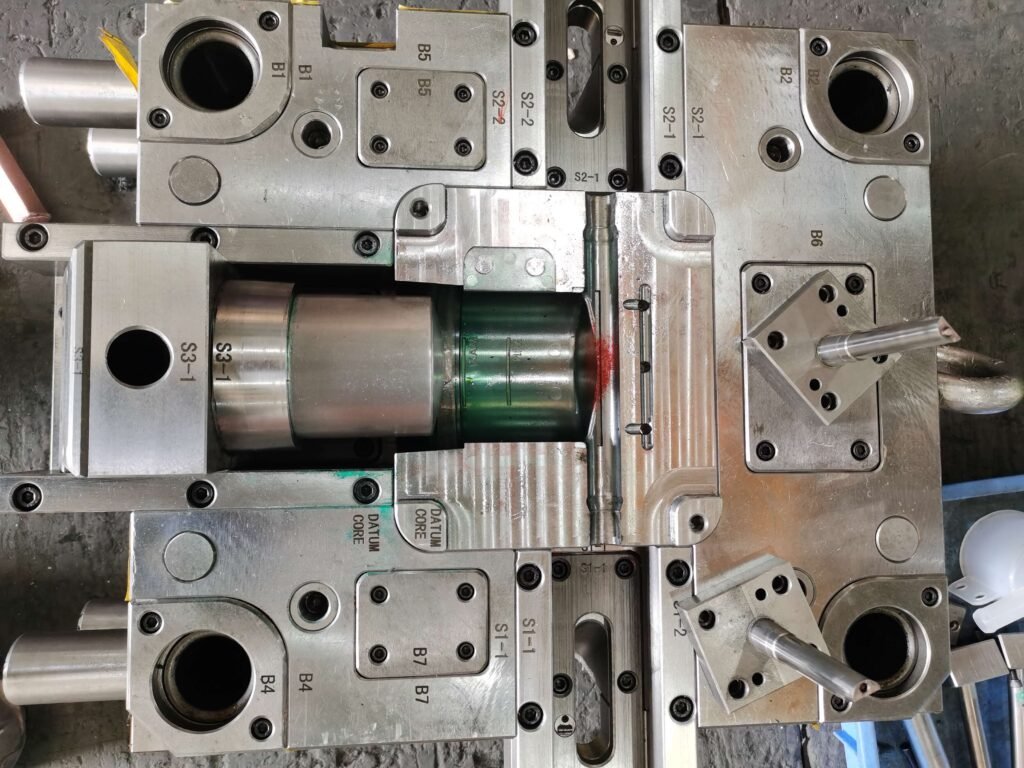

Depending on the size and stage of your company you’ll want a mold for different purposes. One could be to make a prototype of your intended product. You might need some extra design services to ensure your design can get injection molded. Some design features might make a product difficult or impossible to injection mold. A preliminary discussion or consultation with a mold maker can make a lot of difference. So when looking for a mold maker you want one that will offer the full service. You want a one-stop-shop that offers a design assessment for injection molding suitability. A mold maker that also does injection molding will have more practical experience. They can assess your product not only from a technician’s point of view but also from that of a manufacturer. In other words, they have been where you are heading with your mold. So they can offer better advice than a mold maker who only knows how to fabricate molds. Some mold makers are only equipped to make molds but not to use them. A mold might be well made in a technical sense but when put to use the story might change.

Often your mold maker might be in a different country or state. As the world becomes more globalized you have access to mold makers from around the world. You want a mold maker that can get your mold to you on time. That the company has a web presence is one point. This means they are globally connected and understand the importance of this. When working with a mold maker online, you can send the drawing in different formats. You are either sending the designed mold in 3D CAD format or a concept or sketch of the product. The mold maker then designs the mold and builds it. In the latter case, you are searching for a mold maker that also offers mold design services.

You also want a company that places emphasis on customer services and logistics. For example, by visiting www.cavitymold.com. From the home page, you have a good lay out of the process of dealing with the company. From getting a quote to mold testing and the final product. You also have a list of the benefits of being a client. Having an understanding of the stages involved helps you plan time and cost. You can send in your 3D or 2D files in STEP, CAD, or other formats and have a finished mold sent to you.

The final stage is getting the mold. You want to search for a company that can deliver your mold on time. Some mold makers might not have experience with dealing with international customers. Or they might only have an interest in the local customers. You want to know the location and if you will be picking up or having it shipped to you. For this reason, you need to check if the company has a walk in policy or it is all done online.

Guarantee on quality

Company values and culture are indicative of their approach to manufacturing. A company that also does injection molding will understand the importance of a good mold. They would know the impact of a bad mold on production. No injection molder would wish a bad mold on anyone. You should check if the company tests the mold and what type of testing they do.

The guarantee you have on quality depends on different factors. This includes the agreement in place with the mold maker. It is good to have a discussion with the mold maker about the quality of work they aim to deliver. Here you might have to go with intuition. Look at all the other factors discussed in this article. Then you can decide if you reckon the mold maker will deliver the quality you need. It is also important to discuss with the mold maker the standard you need. You should also be willing to pay the right price for good quality. Don’t assume that a high price means the good quality or vice versa. You should understand what is being charged for. Get a price breakdown to know what you are paying for. Bear in mind that the price of your mold does include skill and service rendered. You are also paying for the machine time and tools.

Your Budget

The mold is one of the most important investments in injection molding. You need to dedicate the time and money to get it made well. In the early stage of your planning, you would have contacted mold makers. They would give an estimate of how much it would cost to make the type of mold you need. There is no compromising on the best type of metal to use. There is also no compromising on the functionality and surface finish. So the cost of tooling and material for making a mold is a bit rigid. Where you can get some flexibility is in exchange rates and service charges. Factors like “VIP” treatments, travel, shipping mode amongst others. You also need to consider if you will need to send an engineer over to supervise the process. Good communication and establishing trust can save you a lot of costs. If you are able to communicate well with your mold maker. Then you get relieved of the cost of travel and accommodation. Also, time lost that could have gotten spent on other projects.

Professional relationships

In the long term, you are going to need molds replaced, modified, or serviced. Or you might have a new product range that you need new molds for. Finding a reliable professional mold maker takes time and skill. China offers hundreds and thousands of mold manufacturers. These are at a variety of price and quality. It is about finding the right match. So you want to make the time and skill you have put in to be worth it. This means once you find a reliable mold maker, you kind of want to hang on to them. After all, you have invested all that time and effort to find them. So go into it with the intention of building trust and a long term professional relationship. Also, a mold maker who made the mold would be better qualified to make any modifications or repairs. They know everything about how it got made and the process and materials used. Also, leverage opportunities with smaller companies. Smaller companies might be a bit of risk without as much of a track record as big companies. So like many investments you might have to go with your guts. If it works out well you get great quality at a competitive price. This way you grow with them as a company. You can then leverage this personal assurance you have earned. It makes further transactions faster and easier. Knowing the reliable businesses in China that provide quality is a valuable asset.

You should also consider your social responsibilities and company values. Are you looking to support local businesses?. Or are you looking at strengthening your global network and international relations? Having business partners in a different country does come with some benefits. You can have different aspects of your business to support local businesses. While you have international partners in other areas. So it doesn’t have to be one or the other in this regard.

Conclusion

From the discussion thus far we see that a lot goes into deciding on which manufacturer to go for. China offers a wide variety of mold manufacturing services. You must invest quality time to find the right mold maker that matches your product needs.

Cavity mold has developed high-quality mold for customers across the world. We offer mold design services and injection molding services. Whether you have a 3D CAD drawing of your mold or product or a 2D sketch. You may also have samples of your intended product or mold. We’ll work with you from your concept to ready to use a mold. www.cavitymold.com