Are you struggling to get a flawless, high-gloss finish on your plastic parts? These frustrating surface defects, like weld lines and sink marks, can force you into costly secondary operations like painting or polishing, destroying your project’s budget and timeline. It’s a common headache in molding.

The variothermal process, also known as dynamic mold temperature control, dramatically improves surface quality by rapidly heating the mold surface before injection and then rapidly cooling it after the cavity is filled. This high temperature ensures perfect replication of the mold surface, eliminating defects like weld lines and achieving a high-gloss finish without secondary operations.

I’ve been in the mold-making business for over two decades, and I’ve seen countless projects get stuck on this exact problem. A team designs a beautiful product with a "piano black" finish, but conventional molding just can’t deliver. The parts come out with subtle lines or dull spots that ruin the premium feel. This is where I start talking about a more advanced approach. The variothermal process might sound complex, but it’s one of the most powerful tools we have for achieving perfection straight from the tool. Let’s break down exactly what it is and how it can solve these persistent quality issues.

What Exactly Is the Variothermal Molding Process?

Conventional molding often forces a difficult compromise. You need a cool mold for fast cycle times, but a cool mold can cause the plastic to solidify too quickly, leading to visible imperfections. It’s a constant balancing act. What if you didn’t have to compromise?

The variothermal process involves dynamically heating the mold cavity surface to a temperature above the plastic’s glass transition temperature before the plastic is injected. Once the part is formed, the mold is rapidly cooled to solidify the plastic for ejection. This creates optimal conditions for both the filling and cooling phases within a single production cycle.

Let me explain this in a more practical way. Imagine you’re trying to make a perfect impression of a rubber stamp in cold, stiff wax. You’d have to press really hard, and even then, you might not capture all the fine details. Now, what if you gently heated the surface of the wax first? The stamp would sink in effortlessly, creating a perfect replica. That’s the core idea behind variothermal molding. We aren’t just pushing plastic into a mold; we are creating the perfect conditions for it to flow like water and replicate the mold surface flawlessly.

The Cycle Step-by-Step

A typical injection molding cycle is just two steps: inject and cool. The variothermal process adds a few crucial steps to this sequence.

- Heating Phase: Before the cycle even begins, we rapidly heat the surface of the mold cavity. We’re not heating the whole tool, just the skin of the steel that will touch the plastic. The target temperature is typically above the glass transition temperature (Tg) of the polymer. For a material like polycarbonate (PC), this could mean heating the mold surface to 140°C or higher.

- Injection Phase: With the mold surface hot, we inject the plastic melt. Because the mold is hot, the plastic doesn’t freeze prematurely as it enters. It flows with very low resistance, filling every corner, rib, and tiny textured detail without high pressure. This is where weld lines disappear, as the two melt fronts meeting are both hot enough to fuse together perfectly.

- Cooling Phase: As soon as the cavity is filled and packed, the system instantly switches from heating to cooling. High-pressure cold water or another coolant is flushed through channels right under the mold surface. This quickly drops the temperature, solidifying the part and "locking in" that perfect, high-gloss surface. The part becomes rigid enough for ejection, and the cycle can begin again.

This dynamic control allows us to get the best of both worlds: perfect filling conditions and a reasonably fast cooling time.

What Key Advantages Does Variothermal Control Offer Over Conventional Molding?

Are you constantly battling defects that require costly and time-consuming post-processing like painting or polishing? We’ve seen clients where up to 30% of their production cost was tied up in sanding and coating parts to hide molding flaws. That’s a huge waste of resources.

Variothermal control offers significant advantages, including the virtual elimination of weld lines, sink marks, and flow marks. It enables the creation of high-gloss, defect-free surfaces directly from the mold, improves the replication of micro-features, reduces internal stresses in the part, and can even allow for product designs with thinner walls.

The benefits go far beyond just looking good. For a project manager like Alex, these advantages translate directly into lower costs, better-performing products, and greater design flexibility. I remember a project for a medical device housing where part-to-part consistency was critical. Conventional molding resulted in slight warpage due to internal stress. Switching to a variothermal process not only fixed the warpage by reducing that stress but also gave the housing a premium, sterile-looking finish that the client loved.

Superior Surface Aesthetics

This is the most famous benefit. With variothermal molding, you can achieve a true "Class A" or "piano black" surface without any secondary steps. Weld lines, which form where two plastic flow fronts meet, are a common headache. In a hot variothermal mold, these fronts are still fully molten when they meet, allowing them to fuse together seamlessly, becoming invisible. Similarly, the uniform pressure and slow solidification prevent sink marks over thicker sections like ribs or bosses. The result is a part that looks like it’s been professionally painted, right out of the tool.

Enhanced Structural Integrity and Design Freedom

Because the plastic flows so easily into a hot mold, the required injection pressure is much lower. This drastically reduces the amount of stress molded into the part. Less internal stress means less warpage and improved dimensional stability over the product’s life. This enhanced flowability also opens up new design possibilities. Product designers can create parts with much thinner walls without worrying about the cavity not filling completely. Thinner walls mean less material per part, which leads to lower material costs and lighter products – a huge win in industries like consumer electronics and automotive.

Comparison: Variothermal vs. Conventional

| Feature | Conventional Molding | Variothermal Molding |

|---|---|---|

| Surface Finish | Visible weld lines, flow marks, potential sink marks. | Seamless, high-gloss, defect-free surface. |

| Wall Thickness | Limited by flow; thicker walls often needed. | Thinner walls are possible due to excellent flowability. |

| Internal Stress | Higher, which can lead to part warpage. | Significantly lower, resulting in better dimensional stability. |

| Post-Processing | Often requires painting, polishing, or coating. | Often eliminates the need for any secondary finishing. |

| Micro-features | Poor replication of fine textures and logos. | Excellent, precise replication of micro-structures. |

| Gate Vestiges | Gate marks can be more prominent. | Gate appearance is often improved and less visible. |

How Are Molds Rapidly Heated and Cooled in the Variothermal Process?

The idea of heating and cooling a massive block of tool steel in just a few seconds probably sounds impossible, or at least incredibly energy-intensive. This is a common concern I hear. If you had to heat the entire mold, it would be impractical. The secret lies in a more targeted approach.

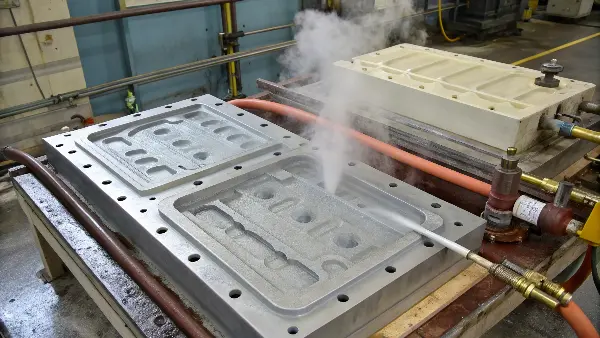

Molds are rapidly heated and cooled using various specialized methods. Common heating techniques include pressurized hot water, steam, or high-frequency induction heating. Cooling is typically achieved by flushing the same channels with cold water. The key is to target only the surface of the mold cavity, not the entire mold block, to ensure rapid temperature changes.

The magic isn’t in heating the whole tool, but in heating a very thin layer—just the "skin" of the mold cavity surface. By focusing the energy right where it’s needed, we can achieve temperature swings of over 100°C in a matter of seconds. This requires not only special external equipment but also very clever mold design, something we’ve spent years perfecting at CavityMold. Let’s look at the primary methods used to achieve this.

Pressurized Fluid Systems (Water/Steam)

This is one of the most common and mature technologies for variothermal control. The mold is built with a network of small channels running just beneath the cavity surface. An external temperature control unit first pumps pressurized hot water (up to 180°C) or steam through these channels to heat the mold face. Once the plastic is injected, the unit instantly switches valves and pumps chilled water through the exact same channels to cool the mold down. The advantage is its reliability and ability to provide very uniform heating and cooling across the entire part surface.

Electric and Induction Heating

A more modern approach uses electricity. This can be done with high-wattage cartridge heaters embedded near the surface, but a more advanced method is induction heating. With induction, a coil is placed behind the cavity insert. When a high-frequency alternating current is passed through it, it generates a magnetic field that rapidly heats the conductive steel surface of the mold. It’s incredibly fast and precise, allowing for zone heating of specific areas. The cooling phase is still typically handled by water channels. This method is great for targeting complex geometries or when extremely fast heating rates are needed.

The Role of Conformal Cooling Channels

Regardless of the heating method, effective cooling is just as important. This is where conformal cooling has become a game-changer. Using advanced techniques like 3D printing of metal mold inserts (Direct Metal Laser Sintering), we can create cooling channels that perfectly follow the contours of the part geometry. Unlike straight-drilled lines in a conventional mold, these channels maintain a consistent distance from the surface everywhere. This ensures that every part of the mold, from flat faces to complex curves, cools down at the same rate, preventing warpage and ensuring a consistent, fast cycle.

Which Applications and Materials Benefit Most from Variothermal Molding?

You have an innovative product design and are targeting a premium market, but you’re unsure if conventional molding can achieve the required look and feel. Choosing the wrong manufacturing process can mean failing to meet customer expectations, which is a risk no project manager wants to take.

Variothermal molding excels in applications requiring premium aesthetics, such as automotive interior components, high-end consumer electronics housings, and medical device enclosures. It is particularly beneficial for amorphous plastics like PC, ABS, and PMMA, and for fiber-filled thermoplastics where it helps to hide the fibers and create a flawless, resin-rich surface.

Knowing where this technology shines can help you decide if it’s the right path for your project. It’s not a universal solution for every plastic part, but for the right application, it is truly transformative. It turns the molding process from a simple forming operation into a finishing operation as well. We often recommend it when a client says the words "no paint," "high gloss," or "no visible fibers."

The World of High-Gloss Finishes

Think about the glossy black trim in a luxury car’s interior, the sleek casing of a new laptop, or the front bezel of a high-end television. These components must be aesthetically perfect. Any blemish, weld line, or dull spot is immediately noticeable and cheapens the product. Variothermal molding is the key to producing these parts with a deep, liquid-like gloss directly from the mold. This not only improves quality but is also more environmentally friendly and cost-effective than processes that rely on spray painting, which involves VOCs (volatile organic compounds) and an extra production step.

Improving Fiber-Reinforced Plastics (FRP)

This is a fantastic and often overlooked application. When you add glass or carbon fibers to a plastic like Nylon or PBT to increase its strength, those fibers can become visible on the surface of the finished part. This creates a rough texture and a "marbled" or swirly look that is unacceptable for many visual components. By using a hot variothermal mold, the plastic melt flows gently, allowing a thin, uniform layer of pure polymer resin to form at the mold surface. This resin-rich skin completely encapsulates the fibers, hiding them from view and creating a perfectly smooth, high-quality finish while retaining the high strength of the composite material underneath.

Micro and Nano-Structure Replication

Because the plastic flows like a low-viscosity liquid into a hot mold cavity, it can perfectly replicate extremely fine details. This is critical for parts with functional micro-structures, such as the tiny channels in a "lab-on-a-chip" medical diagnostic device, or the light-diffusing patterns on an optical lens or light guide. Conventional molding would blur or fail to form these features entirely. Variothermal processing makes it possible to mass-produce complex optical and fluidic components with incredible precision.

What Are the Potential Challenges and Costs of Implementing Variothermal Technology?

This advanced technology sounds incredible, but as a project manager, you’re rightly concerned about the potential impact on your budget and production timeline. It’s a valid concern. Adopting any new process without fully understanding the downsides can lead to unexpected costs and delays that put a project at risk.

The main challenges of variothermal technology are the higher initial investment in specialized mold heating and cooling equipment and the need for more complex, and therefore more expensive, mold designs. The process can also lead to longer cycle times compared to conventional molding, which directly impacts production throughput and part cost.

It’s crucial to have an honest conversation about these factors. Variothermal molding is a problem-solver, but it’s not a free lunch. The decision to use it requires a careful cost-benefit analysis. While the upfront costs are higher, they can often be justified by eliminating expensive post-processing steps and reducing reject rates. Let’s look at the main challenges you need to account for.

Investment in Equipment and Tooling

First, you need the external machinery—the variothermal temperature control unit (TCU). This is a significant piece of capital equipment that sits next to the molding machine. Second, the mold tool itself is more complex and expensive to build. It requires specialized design to incorporate the intricate heating and cooling channels, often needing advanced manufacturing like vacuum brazing or 3D metal printing for conformal channels. The materials and construction must also withstand rapid and repeated temperature cycling. This all adds to the initial tooling investment.

Impact on Cycle Time

Heating the mold before injection and cooling it afterward adds time to every single cycle. A part that might take 30 seconds to produce with conventional molding could take 60 to 90 seconds or more with a variothermal process. This reduction in throughput is a major consideration for high-volume production. You have to weigh the longer cycle time against the time saved by eliminating a separate painting or polishing line. In many cases, the total production time from raw pellet to finished good is actually shorter, but the per-part cost on the molding machine will be higher.

Process Control and Expertise

This is not a "set it and forget it" process. Variothermal molding requires a higher level of process control and technical expertise. The heating rates, cooling rates, switchover timing, and melt temperatures must all be perfectly synchronized and optimized for the specific part and material. It requires skilled technicians and engineers who understand the nuances of the process. This is why partnering with an experienced mold maker and molder like us at CavityMold is so critical. We can help de-risk the process by leveraging our experience to design the right tool and establish a stable, repeatable production window from the start.

Conclusion

The variothermal process is a powerful, advanced technique for specific challenges. It’s the key to achieving unparalleled surface quality and design freedom, especially for high-gloss finishes and fiber-filled parts. It demands careful planning and expertise, but for the right application, it’s a complete game-changer.