Struggling to get high-precision plastic parts right? Choosing the wrong material or a poor design can quickly lead to costly failures and project delays. This uncertainty wastes time, blows budgets, and puts your final product’s quality at risk, making the entire process feel overwhelming.

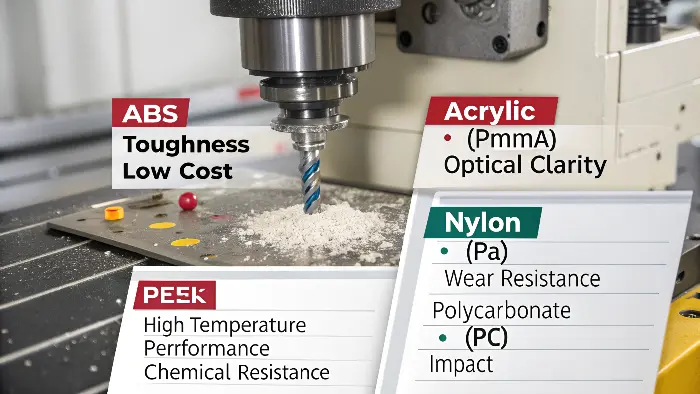

To master CNC machining for plastics, you must select materials based on their specific properties like machinability, thermal stability, and strength. For example, ABS, Nylon, and PEEK are common choices. You also need to follow Design for Manufacturability (DFM) principles, such as keeping uniform wall thicknesses and using generous radii on internal corners. This approach ensures precision, reduces costs, and speeds up production for your custom parts.

It might seem like a lot to juggle, but understanding these core elements is the key to unlocking the full potential of CNC machining. Getting the material and design right from the start saves you countless headaches down the line. But with so many plastics on the market, the first and most important question is always where to begin. Let’s dig into the best materials for the job and why they stand out from the rest.

What plastics are best for CNC machining?

Picking the right plastic often feels like a guessing game. You need a mix of strength, stability, and good machinability, but the sheer number of options is daunting. Making the wrong choice can lead to a part that warps, cracks, or fails to meet critical tolerances, forcing you back to square one.

The best plastics for CNC machining include ABS for its toughness and low cost, Acrylic (PMMA) for optical clarity, and Nylon (PA) for its excellent wear resistance. For more demanding applications, PEEK offers superior high-temperature performance and chemical resistance, while Polycarbonate (PC) provides exceptional impact strength. Your choice should always align with the specific mechanical, thermal, and chemical requirements of your part.

Choosing the right plastic is the foundation of a successful project. One of the first things I learned in this business is that you can’t force a material to do something it’s not meant to do. A beautiful design is useless if it’s made from a plastic that can’t handle the stress of the cutting process or its final application. Let’s break down the most common and reliable options to help you make an informed decision.

Understanding Material Properties

The term "best" is always relative to your project’s needs. A plastic that’s perfect for a simple prototype might be a terrible choice for a functional part in a high-heat environment. When we evaluate materials, we look at several key factors.

- Machinability: This is about how cleanly the material cuts. Good machinability means the plastic forms predictable chips without melting, gumming up the cutting tool, or cracking. Acetal (Delrin) is famous for its outstanding machinability, almost behaving like brass.

- Mechanical & Thermal Stability: Will the part hold its shape under load and when exposed to heat? The friction from CNC cutting generates heat, which can cause some plastics to warp. Materials like PEEK are incredibly stable at high temperatures, while others like ABS require careful speed and feed adjustments to manage heat buildup. I remember a project where we machined a large enclosure from a block of ABS. We had to use specific coolants and slower cutting speeds to prevent the thin walls from deforming.

To make it easier, here is a table comparing some of the top contenders:

| Material | Key Properties | Common Applications | Machinability Notes |

|---|---|---|---|

| ABS | Tough, impact-resistant, low cost | Enclosures, prototypes, consumer products | Good, but can melt at high speeds. |

| Acrylic (PMMA) | Stiff, optically clear, brittle | Lenses, light pipes, display models | Good, but can chip. Requires sharp tools. |

| Nylon (PA66) | High wear resistance, strong, flexible | Gears, bearings, structural components | Fair. Can be slightly abrasive and absorb moisture. |

| Polycarbonate (PC) | Very high impact strength, clear | Safety guards, electronic housings, lenses | Fair. Requires specific tooling to avoid stress cracking. |

| PEEK | High temp & chemical resistance, strong | Medical implants, aerospace parts | Excellent, but very abrasive on tools. High cost. |

| Acetal (Delrin) | Stiff, low friction, dimensionally stable | Bushings, rollers, precision parts | Excellent. Often called the most machinable plastic. |

For project managers like Alex, who are balancing performance and budget, starting with ABS or Acetal is often a safe bet for general-purpose parts. But if the part needs to withstand extreme conditions, investing in a high-performance material like PEEK is non-negotiable.

How much does custom CNC machining cost?

You have a design ready to go, but you have no idea what it will cost to machine. Budgeting for a custom CNC project often feels like a black box, making it difficult to get project approval. This uncertainty can lead to surprise invoices that completely derail your finances and timelines.

The cost of custom CNC machining is driven by material choice, part complexity, required tolerances, order quantity, and total machining time. A simple part made from an affordable plastic like ABS might cost under $100, while a highly complex, tight-tolerance part made from an expensive material like PEEK can cost thousands. Providing a detailed CAD file and clear specifications is the fastest way to get an accurate quote.

One of the most common questions I get from clients is, "Can you give me a ballpark price for this?" While I wish I could, the truth is that cost is tied directly to the details of the part. A few small changes in the design can have a huge impact on the final price. Understanding what drives these costs is the best way for you, as a project manager, to optimize your design and make it more affordable without sacrificing function.

Key Drivers of CNC Machining Costs

Let’s break down the main elements that determine the price of your machined plastic part. Thinking about these factors during the design phase will save you money.

-

### Material Costs

The raw material is the first cost component. A block of ABS is significantly cheaper than a block of PEEK of the same size. PEEK is a high-performance polymer, and its price reflects that. If your application doesn’t require extreme temperature or chemical resistance, choosing a more standard plastic like Acetal or Nylon is an easy way to reduce costs. -

### Machining Time and Complexity

Time is money, especially on a CNC machine. The longer it takes to machine your part, the more it will cost. Complexity is the biggest factor here. A simple block with a few drilled holes is quick to program and machine. An enclosure with complex curves, thin walls, and undercuts requires more programming time, multiple machine setups, and slower cutting speeds. Each time the operator has to re-orient the part to machine a different side (a new setup), it adds time and cost. -

### Tolerances and Finishes

How precise does your part need to be? Standard tolerances (e.g., +/- 0.1 mm) are relatively easy to achieve. But if your part requires very tight tolerances (e.g., +/- 0.025 mm), the machinist has to slow down, use more precise tools, and spend extra time on measurement and inspection. The same goes for surface finish. A standard machine finish is cheapest, but if you need a polished, vapor-smoothed, or painted part, these secondary processes add to the total cost.

This table gives a simple illustration of how these factors play out:

| Factor | Low-Cost Scenario | High-Cost Scenario |

|---|---|---|

| Material | ABS | PEEK |

| Complexity | Simple bracket with 3 holes | Complex housing with undercuts |

| Tolerances | +/- 0.2mm | +/- 0.025mm |

| Quantity | 100+ units | 1 unit (Prototype) |

| Setup | One setup (3-axis) | Multiple setups (5-axis) |

Finally, quantity makes a huge difference due to economies of scale. The initial setup and programming cost is the same whether you make one part or one hundred. That cost gets divided across the total number of parts, so the price-per-part drops significantly with higher quantities.

What materials cannot be CNC machined?

You have a good grasp of what plastics work well, but what about the ones to avoid? Choosing a material that is unsuitable for CNC machining can halt a project before it even starts. You risk wasting time and money on a material that melts, shatters, or jams the equipment, which is a frustrating and entirely preventable setback.

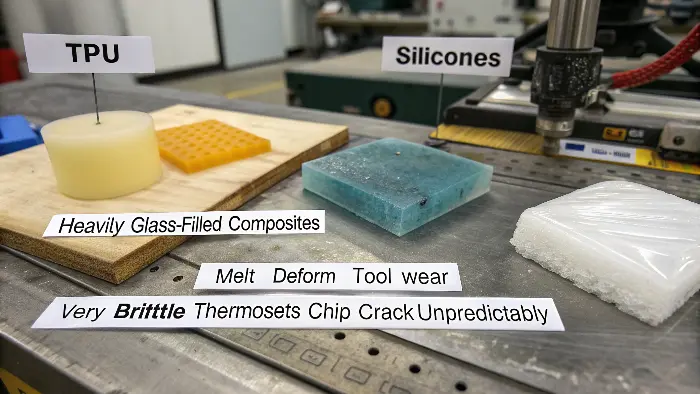

While most rigid plastics can be machined, some materials are problematic. Very soft, flexible materials like some thermoset polyurethanes (TPU) and silicones tend to melt or deform rather than cut cleanly. Extremely abrasive materials, like heavily glass-filled composites, can be machined but cause rapid tool wear, increasing costs. Finally, very brittle thermosets may chip or crack unpredictably.

Knowing what not to use is just as important as knowing what to use. This isn’t just about avoiding a failed part; it’s also about protecting expensive machinery and tools. Over the years, I’ve seen a few experiments with unsuitable materials, and the results are never good. It reinforces the principle of choosing the right manufacturing process for your material, not the other way around.

Diving into Problematic Materials

Let’s look more closely at the types of materials that give machinists a headache and why they are generally avoided for standard CNC jobs.

-

### Soft, Gummy Plastics

The core principle of machining is to create a clean chip. Soft, low-durometer materials like flexible rubbers, silicones, and some TPUs don’t behave this way. Instead of shearing off into a chip, they stretch and deform under the pressure of the cutting tool. The friction generates heat, and because these materials have low melting points, they quickly turn into a sticky, gooey mess that clogs the tool. I remember one project where a client insisted we try to machine a soft gasket. The result wasn’t a part; it was just melted plastic wrapped around a very expensive end mill. For these materials, processes like casting or injection molding are far more suitable. -

### Highly Abrasive Composites

Plastics filled with glass fiber or carbon fiber are incredibly strong and stiff, making them attractive for high-strength applications. However, those same fibers act like sandpaper on cutting tools. While these materials can be machined, it’s a specialized process. Standard high-speed steel (HSS) or even carbide tools will wear down extremely fast, losing their sharp edge and compromising dimensional accuracy. Machining these composites requires very expensive polycrystalline diamond (PCD) tools and can create abrasive dust that is hard on the machine’s components and a potential health hazard if not properly ventilated. -

### Brittle Thermosets

Thermoset plastics, like Bakelite or some epoxies, undergo a chemical change when cured and do not melt when heated. They are often very hard and brittle. When you try to machine them, they don’t cut cleanly. Instead, they are prone to "chipping out," where small fragments break off at the edges of the cut. This makes it nearly impossible to achieve a good surface finish or hold tight tolerances, especially for fine features. While some hard thermosets can be ground, conventional CNC milling is often not the best choice. These materials are typically formed through compression molding.

How long does it take to learn CNC?

As a project manager, you don’t personally operate the CNC machine, but you often feel disconnected from the process your suppliers use. This knowledge gap can make it difficult to have meaningful conversations about timelines, design changes, and cost drivers with your manufacturing partners, leaving you feeling out of the loop.

For a project manager, learning the core concepts of CNC machining—understanding the workflow from CAD to CAM, the basics of G-code, and setup considerations—can be achieved in a few weeks of focused study. This knowledge is invaluable for DFM. Becoming a proficient, hands-on machinist who can handle complex setups and troubleshoot on the fly, however, takes months or even years of practical experience.

You don’t need to become a master machinist to be a great project manager. However, having a solid understanding of the fundamentals will completely change how you interact with your suppliers. I’ve worked with many project managers over the years, and the most successful ones, like Alex, are those who speak the language of manufacturing. It builds trust and allows us to collaborate as true partners to solve problems before they arise.

Why CNC Knowledge Matters for a Project Manager

Instead of focusing on how to operate a machine, let’s focus on what you need to know to manage your projects more effectively.

-

### Understanding the Workflow: CAD to CAM to CNC

This is the digital production chain. Your team creates a 3D model in CAD (Computer-Aided Design) software. That model is then imported into CAM (Computer-Aided Manufacturing) software, where a programmer creates the toolpaths—the exact route the cutting tool will follow. The CAM software then outputs a program called G-code, which is the set of instructions the CNC machine reads to move its axes and create the part. Understanding this flow helps you appreciate that a "simple" design change in CAD can require significant reprogramming work in CAM. -

### The Importance of Setups and Fixturing

A critical part of the process is holding the raw block of plastic securely in the machine. This is done with fixtures or vises. If a part needs features machined on multiple sides, the operator may have to stop the machine and re-clamp the part in a different orientation. Each of these is a "setup." More setups mean more manual labor, more time, and a higher risk of slight misalignment, which affects tolerances. Designing parts that can be machined in a single setup (or as few as possible) is a huge cost saver. -

### Tool Selection and Feature Design

CNC machines use a variety of cutting tools, like end mills and drills, in different sizes. A key DFM principle is to design internal corners with a radius, not a sharp 90-degree angle, because a round cutting tool cannot create a perfectly sharp internal corner. The radius should be slightly larger than the tool you plan to use. Knowing this helps you design parts that are actually machinable.

By grasping these concepts, you can lead more productive DFM discussions, set more realistic timelines, and ask your suppliers smarter questions. Asking, "Will this feature require a new setup on a 3-axis machine, or do you need to move it to a 5-axis?" shows you understand the process and helps you and your supplier find the most efficient manufacturing solution together.

Conclusion

In the end, CNC machining is a powerful and precise method for creating custom plastic parts. Success comes down to pairing the right material, like versatile ABS or high-performance PEEK, with smart design choices. Understanding cost drivers, material limitations, and the basic process helps you deliver high-quality components on time and within budget.