Designing miniature plastic parts presents unique challenges. Weld lines, often a minor cosmetic flaw in larger components, can become critical structural weak points in micro-molded parts. This weakness can lead to unexpected failures, derailing project timelines and driving up costs, a headache no project manager needs.

To manage weld lines in micro-injection molding, focus on strategic gate placement to control where the plastic melt fronts meet. Use high-flow, low-viscosity materials and optimize process parameters like melt temperature and injection speed to ensure a strong bond. Advanced mold design, incorporating features like vent channels and using mold flow simulation, is critical to predict and minimize these defects before the first part is even molded, ensuring structural integrity.

It sounds straightforward, but the devil is in the details when you shrink everything down. I remember working on a project for a client who was developing a tiny medical device connector. A barely visible weld line, which would have been insignificant on a larger part, caused a 30% failure rate during stress testing. That setback forced us back to the drawing board and taught me a valuable lesson: the rules of molding change dramatically at the micro-scale. Let’s break down exactly why these tiny lines cause such big problems and explore what we can do about them.

Why Are Weld Lines a Bigger Problem in Micro-Molding?

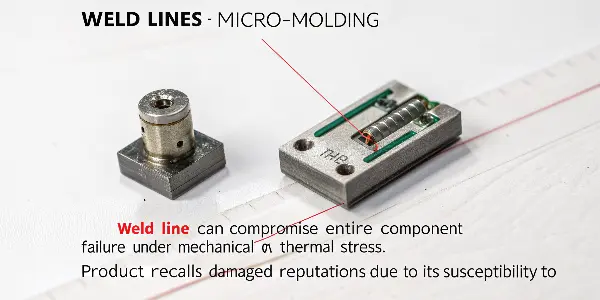

Struggling with unexpected failures in your small, intricate parts? A tiny weld line might be the culprit. At the micro-scale, a weld line isn’t just a cosmetic issue; it’s a significant structural weakness that can compromise the entire component, leading to product recalls and damaged reputations.

Weld lines are a bigger problem in micro-molding because the part’s cross-sectional area is so small that the weld line can represent a large portion of its structure. The rapid cooling rates inherent in micro-molding also prevent polymer chains from properly entangling at the melt front, creating a weak bond. This makes the part highly susceptible to failure under mechanical or thermal stress, turning a cosmetic flaw into a critical defect.

When we talk about traditional injection molding, a weld line is an area where two or more melt fronts meet and cool. On a car bumper, for instance, it might just be a faint line you can see. But in micro-molding, we are dealing with parts that are sometimes smaller than a grain of rice. The physics are completely different.

The Scale and Cooling Effect

The main issue is the high surface-area-to-volume ratio of micro-parts. This causes the molten plastic to cool incredibly fast once it enters the tiny mold cavity. When two melt fronts meet, they have very little time to fuse together before they solidify. The polymer chains don’t get a chance to intermingle and entangle properly. This creates a weak boundary, almost like a pre-formed crack, waiting to fail. On a project involving a miniature gear, we saw parts breaking along the weld line at just 50% of the expected torque. The rapid cooling was literally freezing the weakness into the part’s structure.

From Cosmetic Flaw to Structural Failure

This structural weakness is the core of the problem. What you see as a simple line is actually a point of very high internal stress.

| Factor | Standard Molding | Micro-Molding |

|---|---|---|

| Cooling Rate | Slower, allows for better polymer entanglement | Extremely rapid, prevents proper chain fusion |

| Weld Line Impact | Often cosmetic or a minor strength reduction | A major structural defect, critical failure point |

| Stress Point | Localized weakness | Weakness across a significant part of the structure |

| Design Priority | Aesthetics and minor strength considerations | Structural integrity is the primary concern |

In micro parts, especially those used in medical or electronic applications, this isn’t acceptable. The part’s entire performance life depends on its structural integrity, and a weld line creates an unpredictable and unacceptable risk.

What Design Strategies Can Minimize Weld Lines in Miniature Components?

Are you finding that your miniature component designs are constantly plagued by weak spots? Placing a gate in the wrong spot or overlooking a small design detail can create weld lines exactly where you don’t want them. This can force costly redesigns and push back your production schedule.

To minimize weld lines through design, place a single gate in a location that promotes a sequential, uninterrupted flow path through the part. Avoid features that split the melt front, like holes or pins. If multiple gates are unavoidable, position them to move the weld line to a non-critical, low-stress area. Also, use generous and uniform wall thicknesses to maintain flow velocity and pressure, which helps the melt fronts merge more effectively.

Good design is your first and best defense against weld lines. Before we even think about the material or the molding machine, we need to look at the part geometry itself. I’ve found that focusing on how the plastic will flow is the most important step in the design phase for micro parts. We try to guide the melt front like water through a channel, making its path as smooth and predictable as possible.

The Power of Gate Location

The single most critical design decision is where you place the gate. A gate is the opening where molten plastic enters the mold cavity.

- Single Gate Strategy: Whenever possible, use a single gate. This creates one continuous flow front that fills the cavity without splitting. This eliminates the primary cause of weld lines.

- Weld Line Relocation: If you must use multiple gates or the part geometry naturally splits the flow, the goal becomes control. Position gates so that the inevitable weld line forms in a non-critical area. For a tiny housing I was working on, we ran simulations to place the weld line on a thick, non-load-bearing surface instead of a thin, flexible clip feature.

Geometry and Flow Path Optimization

Beyond gating, the overall shape of the part plays a huge role. Small details can make a big difference in how the plastic flows.

| Design Tactic | Description | Why It Works |

|---|---|---|

| Uniform Wall Thickness | Maintain a consistent wall thickness throughout the part. | Prevents race-tracking, where plastic flows faster through thicker sections and traps air. |

| Generous Radii | Use smooth, rounded corners instead of sharp ones. | Reduces turbulence and pressure drops, helping the melt front maintain its energy. |

| Flow Leaders/Deflectors | Add subtle features to the part geometry to intentionally direct the flow of plastic around obstacles. | Gives you precise control over where the melt front splits and rejoins. |

By thinking about flow from the very start, we can design weld lines out of the part or at least move them somewhere they won’t cause a problem. This proactive approach saves countless hours of troubleshooting later.

How Does Material Selection Impact Weld Lines in Micro Parts?

Choosing the right material feels like a shot in the dark. You pick a resin that meets the part’s functional needs, but during molding, it creates strong weld lines that lead to part failure. This forces you to re-evaluate materials, wasting valuable time and resources on testing and validation.

Material selection is critical for managing weld lines in micro parts. Low-viscosity, high-flow-rate materials like LCP, PEEK, or specific grades of nylon and polycarbonate are ideal. These materials fill the tiny cavities quickly and with less pressure, allowing the melt fronts to arrive hotter and merge more completely. Using materials with fillers like glass fibers can actually worsen weld line strength, as the fibers align with the flow and don’t bridge the gap effectively.

Even the best-designed part will fail if you use the wrong material. For micro-injection molding, the material’s flow characteristics are just as important as its mechanical properties. The tight spaces and rapid cooling demand a resin that can move quickly and easily. I once saw a project struggle for weeks because the team insisted on using a standard grade of polycarbonate. Switching to a high-flow medical grade of the same material solved the weld line problem almost overnight.

The Importance of Flow Characteristics

Viscosity is a measure of a fluid’s resistance to flow. In micro-molding, low viscosity is your best friend.

- Low-Viscosity Resins: Materials like Liquid Crystal Polymer (LCP) and certain grades of Polyether Ether Ketone (PEEK) are naturally very fluid when molten. They behave more like water than honey. This allows them to fill complex, tiny features without requiring extreme injection pressures, which can damage the mold or the part.

- Melt Flow Index (MFI): When you look at a material datasheet, pay close attention to the MFI. A higher MFI indicates better flowability. For micro-molding, we always look for materials at the high end of the MFI spectrum for their polymer family.

Fillers and Their Unintended Consequences

Adding fillers like glass or carbon fibers is a common way to increase the strength and stiffness of a plastic part. However, in micro-molding, they can be a double-edged sword.

| Material Type | Weld Line Strength | Flow Characteristics | Common Applications |

|---|---|---|---|

| Unfilled Resins | Generally better | Smoother flow, less orientation at the weld line | Connectors, lenses, intricate housings |

| Filled Resins (e.g., Glass-filled) | Often weaker | Fibers align with flow, don’t cross the weld line | High-stiffness structural components |

| High-Flow Polymers (LCP, PEEK) | Excellent | Very low viscosity, fills complex geometries easily | Medical devices, high-frequency electronics |

When a fiber-filled material flows, the fibers act like logs in a river. They align themselves parallel to the direction of flow. When two melt fronts meet at a weld line, these fibers line up alongside each other but don’t cross over to bridge the gap. This creates a resin-rich, fiber-poor area that is significantly weaker than the rest of the part. Whenever possible, we recommend designing the part to be strong enough with an unfilled, high-flow material to avoid this issue entirely.

What Role Does Mold Design Play in Preventing Weld Lines?

You’ve optimized the part design and selected the perfect material, but you’re still getting bad weld lines. The problem might be hidden in your mold design. Poor venting or inefficient heating can ruin a part before the plastic even solidifies, causing delays and forcing expensive mold rework.

A good mold design is crucial for preventing weld lines. It must include strategic venting at locations where melt fronts will meet to allow trapped air to escape, preventing back pressure that weakens the bond. The mold should also have an advanced thermal management system with precise heating channels to maintain a high, uniform temperature. This keeps the plastic molten longer, giving the melt fronts more time to fuse properly before cooling.

The physical mold is the final piece of the puzzle. It’s where all our design, material, and process planning comes together. For micro-molding, a mold isn’t just a cavity; it’s a highly engineered piece of equipment designed for extreme precision and thermal control. I’ve learned that you can’t cut corners on the mold. A little extra investment in advanced mold features pays for itself by preventing production headaches.

Venting: Letting the Air Out

As molten plastic rushes into the mold cavity, it pushes the air that’s already there out of the way. If that air has nowhere to go, it gets compressed and trapped, creating a pocket of superheated gas. This trapped air acts like a roadblock.

- Impact on Weld Lines: When melt fronts try to merge in an area with trapped air, the air pocket prevents them from making good contact. The plastic cools around the air pocket, resulting in a weak or incomplete weld.

- Micro-Venting Solutions: In micro-molding, vents can be incredibly small, sometimes just a few microns deep. We strategically place these vents at the last point to fill, which is often right where a weld line is predicted to form. This allows the trapped air and any volatile gases from the resin to escape, ensuring a solid, strong fusion.

Thermal Management: Keeping it Hot

Heat is energy. We need to keep the molten plastic as hot as possible for as long as possible to give the polymer chains time to entangle at the weld line.

| Mold Feature | Function | Benefit for Weld Lines |

|---|---|---|

| Conformal Cooling/Heating | Channels that follow the shape of the part cavity for uniform temperature control. | Ensures the entire melt front is at an optimal temperature, promoting a strong bond. |

| High-Conductivity Inserts | Use of materials like beryllium-copper in specific areas of the mold. | Allows for targeted heating of areas where weld lines are expected to form. |

| Mold Insulation | Insulating plates that prevent heat from escaping from the mold. | Maintains a stable and high mold temperature, reducing premature cooling. |

By combining precise venting with advanced thermal management, a well-designed mold creates the ideal environment for a strong weld. It ensures the melt fronts meet with maximum heat and minimal resistance, allowing them to fuse into a single, robust structure.

Conclusion

Managing weld lines in micro-injection molding comes down to a holistic approach. You can’t just focus on one area. Success requires careful part design, smart material selection, precise process control, and an expertly engineered mold. By considering these factors together, you can turn a critical weakness into a manageable issue.