Are you tired of dealing with injection molding defects like burn marks and short shots? These issues can ruin part quality and drive up production costs. A vacuum-assisted venting system offers a powerful solution by actively removing trapped air, ensuring a flawless molding process every time.

A vacuum-assisted venting system uses a vacuum pump to actively remove air and gases from the mold cavity before and during the injection process. This prevents gas-related defects like short shots, burn marks, and weld lines. It ultimately improves part quality, reduces cycle times, and allows for more complex part designs, delivering superior performance over traditional venting methods.

I’ve been in the mold making business since 2009, and I’ve seen countless projects struggle with gas-related problems. These issues are frustrating for project managers like Alex, who need reliable parts delivered on time. Traditional venting has its limits, especially with complex parts or demanding materials. That’s why understanding advanced solutions like vacuum venting is so important. It’s a technology that can truly elevate your production capabilities. Let’s dig deeper into how it works and what it can do for you.

How Does a Vacuum-Assisted Venting System Actually Work in Injection Molding?

It’s one thing to hear about a new technology, but another to understand its inner workings. If you don’t grasp the core mechanism, you can’t effectively implement it or troubleshoot potential issues. Let’s break down the entire process into simple, understandable steps to see exactly what’s happening inside your mold.

It works by sealing the mold parting line and connecting a vacuum pump to dedicated vent ports. Before injection, the pump evacuates air from the cavity, creating a near-vacuum. As molten plastic is injected, any remaining gases or volatiles from the resin are also actively suctioned out. This ensures the cavity is completely filled with plastic, free from trapped air.

To really get what’s going on, let’s look at the key parts and the process itself. It’s not as complicated as it sounds. Think of it as giving the plastic a perfectly clear runway to fill the mold, with no air trying to get in the way. At CavityMold, we’ve integrated these systems for clients working on high-spec projects, and the results are consistently impressive. It starts with having the right components working together seamlessly with your molding machine.

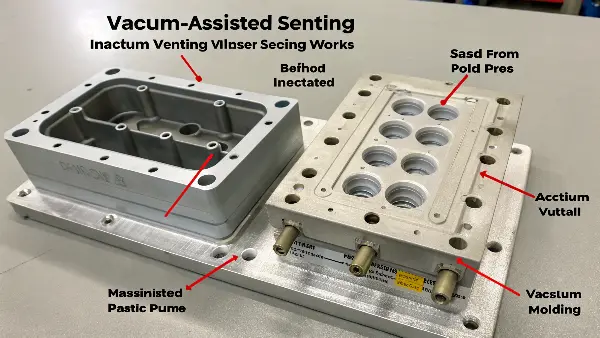

The Core Components of a Vacuum Venting Setup

A successful vacuum venting system is more than just a pump. It’s a coordinated setup where each part plays a crucial role. Without all the pieces in place, you won’t get the performance you’re looking for.

- Vacuum Pump: This is the heart of the system. It creates the negative pressure needed to suck the air out of the mold cavity. The size and power of the pump must match the volume of the mold and the required evacuation speed.

- Seals: To create a vacuum, the mold must be airtight. O-rings or other custom seals are placed around the cavity perimeter on the parting line. This is probably the most critical part of the implementation. A poor seal means the system can’t hold a vacuum, making the whole setup useless.

- Vacuum Valves and Ports: These are the gateways. Ports are machined into the mold, connecting the cavity to the vacuum lines. Valves, controlled by the molding machine, open and close at precise times to pull the vacuum and then release it before the mold opens.

- Controller: This unit synchronizes the vacuum pump and valves with the injection molding machine’s cycle. It tells the pump when to start pulling air and when to stop. Modern systems are highly integrated for precise timing.

The Step-by-Step Operating Cycle

Here’s how these components work together during a single molding cycle.

| Stage | Mold Status | Vacuum System Status | Plastic Flow Status |

|---|---|---|---|

| 1. Mold Clamping | Mold closes | Seals on parting line are compressed, creating an air-tight seal | No flow |

| 2. Evacuation | Mold fully clamped | Controller signals valve to open; pump activates, pulling air from the cavity | No flow |

| 3. Injection | Mold fully clamped | Pump continues to run, removing both air and any gases from the plastic | Plastic fills the cavity |

| 4. Holding/Cooling | Mold fully clamped | Pump is turned off, and the valve closes to hold pressure | Plastic solidifies |

| 5. Mold Opening | Mold begins to open | Vent valve may open to equalize pressure, helping with part ejection | Part is solid |

This process eliminates the back pressure that trapped air creates, allowing the molten plastic to flow more freely and fill every detail of the mold.

What Key Performance Benefits Does Vacuum Venting Offer for Your Molds?

You might be thinking, "This sounds great, but what’s the real payoff?" Investing in new technology needs a clear return, especially when you’re responsible for budgets and timelines. The good news is, the benefits are both significant and measurable, impacting everything from part quality to your bottom line.

Vacuum venting dramatically improves part quality by eliminating gas-related defects like burn marks, incomplete fills, and weak weld lines. It also enables the use of lower injection pressures, which reduces clamp tonnage requirements and tool wear. This leads to faster cycle times, lower energy consumption, and the ability to produce thinner-walled, more complex parts that would be impossible with traditional venting.

I remember a project with a client in the medical device industry. They were struggling with a complex polycarbonate part that had very thin walls. With conventional venting, they were getting a 30% scrap rate due to short shots and burn marks at the end of fill. After we retrofitted their mold with a vacuum venting system, their scrap rate dropped to under 1%. The benefits are not just theoretical; they solve real-world production headaches.

Eliminating Common Molding Defects

Trapped gas is the root cause of many persistent molding problems. By actively removing air, you directly attack these issues at the source.

- No More Burn Marks: Burn marks, or dieseling, happen when trapped air gets compressed so quickly that it ignites, scorching the plastic. A vacuum removes the air, so there’s nothing left to compress and burn.

- Complete Cavity Filling: Air trapped in the mold works against the plastic flow, creating back pressure that can prevent the melt from reaching the furthest points of the cavity. This causes short shots or incomplete fills. Vacuum venting eliminates this back pressure, allowing the plastic to fill every tiny feature effortlessly.

- Stronger Weld Lines: Weld lines form where two plastic melt fronts meet. If gas is trapped at this meeting point, it creates a weak spot or a visible flaw. By ensuring the cavity is free of air, vacuum venting allows the melt fronts to fuse together much more effectively, resulting in stronger and less visible weld lines.

Expanding Your Design and Processing Capabilities

The benefits go beyond just fixing defects. Vacuum venting opens up new possibilities for what you can design and how efficiently you can produce it.

| Capability Enhancement | How Vacuum Venting Enables It | Impact for Project Managers |

|---|---|---|

| Thinner Wall Sections | Lower flow resistance allows plastic to travel further into thin sections without freezing off prematurely. | Design lighter, more material-efficient parts without compromising on fill quality. |

| Use of High-Viscosity Resins | Difficult-to-flow materials like high-temperature plastics or heavily filled resins can be molded with lower pressures. | Broader material selection for demanding applications; improved performance characteristics. |

| Lower Injection Pressures & Clamp Tonnage | With no air back pressure, less force is needed to push the plastic into the cavity. This also means less clamp force is required to keep the mold shut. | Reduced wear and tear on the mold and molding machine. Potential to run jobs on smaller, more energy-efficient presses. |

| Reduced Cycle Times | Faster injection speeds are possible without the risk of burning. Lower pressure can also mean a shorter holding time. | Increased production output and lower per-part cost, helping you meet tight deadlines. |

By adopting this technology, you’re not just making better parts; you’re making your entire manufacturing process more robust, efficient, and versatile.

How Can You Successfully Implement a Vacuum Venting System?

Knowing the benefits is one thing, but making it happen is another challenge. A poor implementation can lead to frustration and wasted investment. Success depends on careful planning and precision from the mold design stage through to the final setup on the press. It requires a different mindset than traditional mold making.

Successful implementation starts with designing the mold for vacuum from the beginning. This includes integrating grooves for O-ring seals on the parting line and strategically placing vacuum ports. The system must be properly sized and connected, ensuring all seals are perfectly leak-proof. Finally, the vacuum cycle must be precisely synchronized with the injection molding machine’s controller for optimal performance.

From our experience at CavityMold, trying to retrofit a mold not designed for vacuum is much harder than building it in from the start. We always advise clients like Alex to consider vacuum venting during the initial design phase if the part is complex or the material is tricky. Getting the foundation right—especially the seal—is 90% of the battle. Let’s walk through the critical steps for a successful implementation.

Step 1: Design for a Perfect Seal

The entire system relies on the mold’s ability to hold a vacuum. If air can leak in from the outside, the pump will be ineffective.

- Parting Line Seals: The most common method is machining a groove around the cavity perimeter and any inserts on the parting line. An O-ring, typically made from a durable material like Viton, is fitted into this groove. When the mold closes, the O-ring is compressed, creating a perfect seal. The groove depth and width must be precisely calculated to ensure the right amount of compression—too little and it leaks, too much and the O-ring will be damaged.

- Sealing Ejector Pins and Slides: Any moving component that passes through the mold plates is a potential leak path. Ejector pins, slides, and lifters must also be sealed. This can be done with smaller O-rings or specialized sealing components designed for moving parts. Ignoring these can undermine the primary parting line seal.

Step 2: Strategic Placement of Vacuum Ports

You need to pull the air from the right places. The goal is to evacuate the cavity and runners just ahead of the plastic melt front.

- Location, Location, Location: Vacuum ports should be placed at the last-to-fill areas of the cavity and at the end of runners. You can use mold flow analysis software to accurately predict these locations. Placing them incorrectly can result in plastic flowing into the vacuum lines, which is a major problem to clean up.

- Using Porous Inserts: For very complex areas, a great technique is to use inserts made of porous steel. This material allows air to pass through but is too dense for the molten plastic to penetrate. Placing a porous steel insert at a last-to-fill location and connecting the vacuum line behind it is a highly effective way to vent difficult spots.

Step 3: Integration and Synchronization

The vacuum system must work in harmony with the molding machine.

- Connecting the Hardware: The vacuum pump is connected to the mold’s ports via flexible or hard-plumbed lines. A control valve is installed in this line, which is wired to the molding machine’s controller.

- Programming the Cycle: You need to program the machine’s sequence to manage the vacuum. The controller must be set to:

- Signal the vacuum valve to open and the pump to start after the mold is fully clamped but before injection begins.

- Keep the vacuum active during injection.

- Shut off the vacuum and release the pressure before the mold opens to prevent the part from sticking.

Proper timing is crucial for efficiency and preventing damage to the mold or system.

What Common Challenges Should You Watch Out for With Vacuum Venting?

While vacuum venting is a powerful tool, it’s not a magic bullet. Like any advanced process, it comes with its own set of potential challenges. Being aware of these upfront can save you a lot of time and frustration, ensuring your implementation is smooth and effective.

The most common challenge is maintaining a perfect vacuum seal; leaks from worn O-rings or unsealed ejector pins are frequent issues. Another problem is plastic accidentally getting sucked into the vacuum lines if ports are poorly placed or injection parameters are wrong. Finally, there’s the added complexity and cost of initial setup and maintenance, which requires more skilled technicians.

I’ve had calls from companies who tried to implement vacuum venting themselves and ran into trouble. Often, the issue boils down to a small, overlooked detail, like a tiny leak in a seal or a mis-timed valve. These systems demand precision. Anticipating these challenges is key to building a robust process that you can rely on cycle after cycle. Let’s look at these problems and how to solve them.

Problem 1: Vacuum Leaks

A leaky system is an ineffective system. The pump will run constantly without achieving the target vacuum level, wasting energy and failing to provide any of the molding benefits.

- Root Causes:

- Worn or Damaged O-rings: O-rings are wear items. Over time, the heat and pressure of the molding process will cause them to degrade.

- Dirty Parting Line Surfaces: Any small piece of debris, grime, or even a build-up of mold release agent on the parting line can prevent the seal from closing properly.

- Unsealed Mold Components: Forgetting to seal ejector pins, lifters, or slides is a common oversight. Air will get sucked in around them.

- Solutions:

- Regular Inspection and Replacement: Implement a preventive maintenance schedule to check seals and replace them before they fail.

- Cleanliness Protocol: Enforce strict mold cleaning procedures. The parting line surfaces must be spotless before every production run.

- Thorough Mold Design: Ensure every potential leak path is identified and sealed during the mold design phase. Using a checklist can help.

Problem 2: Plastic Contamination in Vacuum Lines

This is a serious issue that can shut down production. If molten plastic enters the vacuum ports, it can solidify and block the lines, potentially damaging the valves and even the pump itself.

- Root Causes:

- Incorrect Port Placement: Placing a vacuum port in an area that fills early in the injection cycle is a recipe for disaster.

- Excessive Injection Speed or Pressure: If you inject too fast or with too much pressure, the plastic can flash into the vent channel before the air has been evacuated.

- Delayed Vacuum Shut-off: If the vacuum isn’t turned off at the right time, plastic can be pulled into the port during the holding phase.

- Solutions:

- Use Mold Flow Analysis: This is the best way to determine the absolute last-to-fill points for correct port placement.

- Install Resin Traps: Place a filter or trap in the vacuum line near the mold to catch any plastic that might get through before it reaches the main valve or pump.

- Process Optimization: Start with conservative injection parameters and gradually increase them while monitoring the process. Ensure the vacuum control timing is programmed correctly.

Problem 3: Increased Complexity and Maintenance

A vacuum system adds more components and another process variable to manage. This requires a higher level of skill from your setup technicians and maintenance team.

- Challenges:

- Higher initial investment in the mold and auxiliary equipment.

- More complex setup procedures.

- Additional maintenance tasks (checking seals, cleaning filters, servicing the pump).

- Solutions:

- Proper Training: Invest in training for your technical staff. They need to understand how the system works, how to set it up correctly, and how to troubleshoot it.

- Standardized Procedures: Create clear, documented standard operating procedures (SOPs) for setup, operation, and maintenance.

- Partner with Experts: Work with an experienced mold maker like CavityMold who can provide a turnkey solution and support you through the implementation process.

Conclusion

In short, vacuum-assisted venting is a transformative technology for injection molding. It eliminates gas-related defects, improves part quality, and unlocks new design possibilities. By understanding its implementation and benefits, you can greatly enhance your manufacturing capabilities and achieve superior results for even the most demanding projects.