Struggling to balance speed and quality in your injection molding projects? Incorrect settings can lead to costly defects and delays, putting your entire production schedule at risk. Understanding the critical interplay of temperature, pressure, and cooling is the key to unlocking efficient, defect-free manufacturing.

Temperature, pressure, and cooling time are fundamentally linked in injection molding. Higher melt temperatures require longer cooling times to solidify the part. During this cooling phase, holding pressure must be maintained to pack the mold and prevent defects like sink marks. Optimizing these three variables together is essential to minimize cycle times, ensure dimensional stability, and produce high-quality parts consistently.

Mastering this balance isn’t just about tweaking numbers on a machine; it’s about deeply understanding the physics of the process. Each parameter directly influences the others and, ultimately, the success of your final product. When you get it right, you save time, reduce waste, and deliver superior components. But get it wrong, and you’re left troubleshooting problems that could have been avoided. Let’s break down how these elements work together so you can gain better control over your production outcomes.

What Key Factors Influence Cooling Time in Injection Molding?

Have you ever noticed your cycle times are inconsistent, suspecting cooling is the culprit but not knowing exactly why? This unpredictability can derail your project schedule, causing missed deadlines and budget overruns. Let’s pinpoint the specific factors that control cooling time so you can manage your process more effectively.

The main factors affecting cooling time are part wall thickness, molten plastic temperature, mold temperature, and the thermal properties of the plastic and mold materials. Thicker walls take much longer to cool, and higher melt temperatures also extend the cooling phase. Beyond materials, the design and efficiency of the mold’s cooling channels play a huge role in removing heat quickly and evenly from the part.

To truly optimize your projects, you have to look beyond the machine’s cooling timer setting. The time needed for a part to solidify is dictated by real-world physics, not just a number on a screen. A project manager who understands these underlying factors can work with designers and mold makers to create a more efficient process from the very beginning. I’ve seen firsthand how a small design change can dramatically cut cooling time and boost output. Let’s look closer at these critical elements.

Part Design and Wall Thickness

This is the most significant factor. The time it takes for heat to escape a part is related to the square of its thickest section. This means doubling the wall thickness can actually quadruple the required cooling time. This is why uniform wall thickness is a core principle of good part design. When I review a part for manufacturability, I immediately look for thick sections, as they will dictate the entire cycle time. These areas are also prone to defects like sink marks and voids because the core material cools much slower than the surface.

Material and Mold Properties

| Every material behaves differently. The choice of plastic resin and mold material creates a unique thermal equation for every project. | Property | Impact on Cooling Time | Example |

|---|---|---|---|

| Plastic Thermal Diffusivity | A higher value means the material can transfer heat faster, reducing cooling time. | Amorphous plastics like PC generally take longer to cool than semi-crystalline ones like PP. | |

| Melt Temperature | A higher melt temperature means more heat needs to be removed from the part, increasing cooling time. | Running a material at the high end of its recommended range will extend the cycle. | |

| Mold Temperature | A cooler mold creates a larger temperature difference, pulling heat from the part faster. | Running a mold too cold can cause flow issues and surface defects, so a balance is needed. | |

| Mold Material Conductivity | High-conductivity mold materials like aluminum or beryllium copper pull heat away much faster than standard P20 steel. | This can significantly shorten cooling times but comes at a higher tooling cost. |

Cooling Channel Design

Finally, how you remove the heat from the mold is critical. The design of the cooling channels—their diameter, layout, and distance from the cavity surface—directly impacts efficiency. Poorly designed channels can create hot spots on the mold, leading to warpage and inconsistent part quality. Advanced techniques like conformal cooling, where channels follow the contours of the part, offer the most effective heat removal and can drastically reduce cooling time for complex geometries.

What Does Cooling Time Affect?

Ever wonder why a part that looks perfect right out of the mold ends up warped or cracked hours later? The problem often starts with improper cooling, a hidden issue that can undermine part quality and your project’s reputation. Don’t let insufficient cooling turn a successful production run into a pile of rejects.

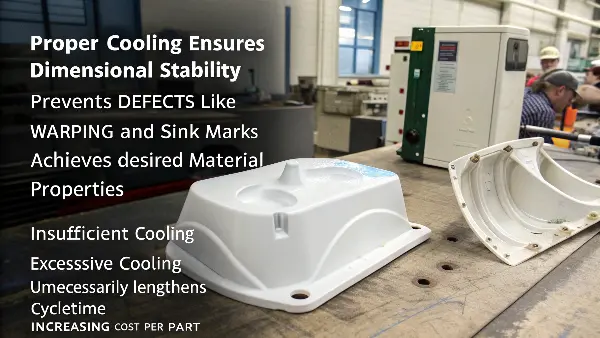

Cooling time directly impacts three critical areas: part quality, cycle time, and production cost. Proper cooling ensures dimensional stability, prevents defects like warping and sink marks, and achieves the desired material properties. Insufficient cooling leads to defects, while excessive cooling unnecessarily lengthens the cycle time, which in turn increases the cost per part and reduces overall production efficiency. It’s a delicate balance.

The cooling phase often accounts for over half of the entire injection molding cycle. For a project manager like Alex, this means cooling time is the biggest lever you can pull to increase throughput and reduce costs. But it’s a lever with consequences. Rushing the cooling phase to shorten cycle times almost always backfires. I once worked on a project where we tried to shave a few seconds off the cooling time to meet an aggressive deadline. We ended up with a high scrap rate due to warpage, which forced us to spend more time and money fixing the issue than we initially "saved."

Impact on Part Quality and Performance

This is the most immediate and visible consequence. The cooling process sets the final shape and internal structure of the plastic.

- Dimensional Stability: If a part is ejected before it is fully solidified and stable, it will continue to shrink and warp outside the mold. This leads to parts that are out of tolerance and may not fit or function correctly in the final assembly.

- Surface Finish: Rushing the cooling or having uneven mold temperatures can cause surface defects. These include sink marks, which are small depressions that form over thick sections, and blush marks from internal stresses.

- Mechanical Properties: The rate of cooling influences the crystallinity of semi-crystalline plastics. Slow cooling allows larger crystal structures to form, which can affect properties like strength, stiffness, and impact resistance. The wrong cooling time means you might not get the material performance you specified in your design.

Impact on Cycle Time and Cost-Effectiveness

Since cooling is the longest part of the cycle, any change has a major effect on production economics. A longer cycle means fewer parts produced per hour, which directly increases the manufacturing cost of each unit. For high-volume production runs, even a few seconds of unnecessary cooling time can add up to thousands of dollars in lost machine time and reduced output over the course of the project. This is why accurately calculating and optimizing cooling time is not just a technical exercise—it’s a critical business decision. It’s about finding the sweet spot where you achieve perfect quality in the shortest possible time.

How Do You Calculate Cooling Time in Injection Molding?

Are you relying on trial and error to set your cooling times? This guesswork leads to inconsistent quality and wasted machine time as you slowly dial in the process for each new mold. Imagine being able to predict a reliable starting point for your cooling time before the first part is even molded.

You calculate cooling time in injection molding by using theoretical formulas as a baseline, then refining the result through Moldflow analysis and practical trials. The initial calculation considers key inputs: the part’s maximum wall thickness, the plastic’s thermal properties, the melt temperature, and the desired ejection temperature. This gives a solid theoretical estimate that saves significant time and material during the initial machine setup and optimization phase.

In my experience as an engineer, starting with a good calculation is half the battle. It turns an unknown variable into a manageable parameter. Instead of starting from zero, my team and I can use a calculated estimate to set up the machine. This allows us to produce a good part much faster. From there, we can make small, informed adjustments to optimize the cycle. This methodical approach is far more efficient than random guessing. It provides a structured framework for process validation, making it easier to document and replicate successful setups for future production runs.

The Foundational Approach: Theoretical Calculation

The first step is always to establish a theoretical baseline. This involves using a mathematical formula that models the heat transfer process. While we’ll look at a specific formula next, the key inputs for any calculation remain the same:

- Maximum Wall Thickness (t): As we’ve discussed, this is the most critical variable. You must identify the thickest section of your part, as it will dictate the overall cooling time.

- Material and Mold Temperatures: You need three key temperature values:

- Melt Temperature (Tm): The temperature of the plastic as it enters the mold.

- Mold Wall Temperature (Tw): The surface temperature of the mold cavity.

- Ejection Temperature (Te): The temperature at which the part is rigid enough to be ejected without deforming. This is a property of the specific plastic being used.

- Thermal Diffusivity (α): This is a material property that measures how quickly heat diffuses through the plastic. You can find this value on the material’s technical data sheet. It combines thermal conductivity, density, and specific heat capacity into a single, useful number.

Refining the Estimate: Simulation and Practical Testing

A formula provides a great starting point, but it’s a simplification of a complex process. To get closer to the optimal time, we turn to more advanced tools and real-world testing.

- Moldflow Analysis: Software like Moldflow simulates the entire injection process. It can predict how heat will be removed from every point on the part, accounting for complex geometries and the layout of cooling channels. This analysis provides a much more accurate cooling time prediction and helps identify potential hot spots that could lead to defects.

- DOE and Practical Trials: Once the mold is on the machine, we perform a Design of Experiments (DOE) or methodical trials. We start with the calculated or simulated cooling time and produce a small batch of parts. We then carefully inspect them for quality and dimensional accuracy. Based on the results, we make small adjustments to the cooling time, holding pressure, and other parameters until we find the optimal balance of quality and cycle speed.

What Is the Formula for Cooling Time of Mold?

Do you want to move beyond estimation and use a concrete formula to guide your process setup? Relying only on past experience can be limiting, especially with new materials or complex part designs. Having a mathematical starting point brings precision and predictability to your planning.

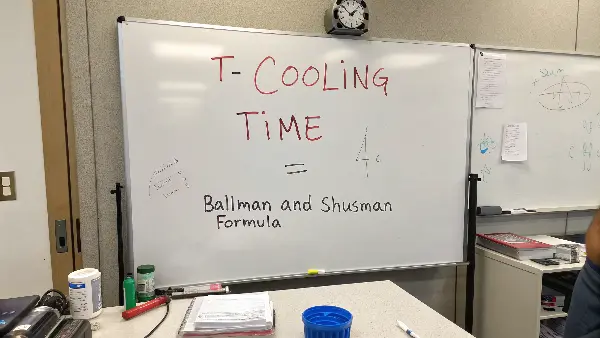

*A common formula for estimating cooling time (t_cooling) is the "Ballman and Shusman" formula. It is expressed as: t_cooling = (t² / (π² α)) ln( (4/π) ((Tm – Tw) / (Te – Tw)) ). This equation calculates the time needed for the center of the part’s thickest section to cool to a safe ejection temperature. It provides a scientifically-backed estimate for initial machine setup.**

While this formula might look intimidating, it’s a powerful tool once you understand its components. Think of it as a recipe. If you have the right ingredients (your variables), you can get a very reliable result. At CavityMold, we use this and other similar formulas as a first step in our process development. It allows us to provide our clients with more accurate cycle time estimates early in the project. Breaking this formula down shows how each parameter we’ve discussed mathematically contributes to the final cooling time.

Breaking Down the Formula

Let’s dissect the formula to understand what each part represents and why it’s there. Understanding the ‘why’ makes it much easier to apply in practice.

t_cooling = (t² / (π² * α)) * ln( (4/π) * ((Tm - Tw) / (Te - Tw)) )

Let’s look at the two main parts of this equation.

Part 1: The Heat Diffusion Component (t² / (π² * α))

This part of the formula describes how quickly heat can physically move out of the plastic.

t²(Wall Thickness Squared): This term gives mathematical weight to the most critical factor. The square relationship means that even a small increase in wall thickness has an exponential impact on cooling time. It confirms why uniform and minimal wall thickness is paramount.α(Thermal Diffusivity): This is in the denominator, meaning a higher thermal diffusivity reduces cooling time. This makes sense—if a material is good at transferring heat (highα), it will cool down faster.π²(Pi Squared): This is a constant that arises from solving the heat conduction equations for a flat plate geometry, which is the simplification used to model the part’s wall.

Part 2: The Temperature Ratio Component ln( (4/π) * ((Tm - Tw) / (Te - Tw)) )

This part of the formula deals with the temperature differences that drive the cooling process. It’s wrapped in a natural logarithm (ln), which means that large changes in temperature ratios have a diminishing effect on the final cooling time.

(Tm - Tw)(Melt Temp – Mold Temp): This is the initial temperature difference. A larger gap between the hot plastic and the cool mold will drive heat out faster.(Te - Tw)(Ejection Temp – Mold Temp): This represents the temperature difference at the end of the cooling cycle.- The Ratio

((Tm - Tw) / (Te - Tw)): This ratio essentially compares the total amount of heat that needs to be removed to the temperature condition at ejection. A larger ratio means more cooling is required, thus increasing thet_cooling.

Using this formula gives you a powerful, data-driven starting point that is far superior to guesswork.

Conclusion

Mastering the relationship between temperature, pressure, and cooling time is fundamental to successful injection molding. By understanding how wall thickness, material choice, and mold design affect these parameters, you can move from trial-and-error to a predictive, science-based approach that ensures both quality and efficiency.