Struggling to design plastic parts that are strong, lightweight, and cost-effective? Getting this balance wrong can lead to weak products, ugly sink marks, and wasted material, derailing your project’s budget and timeline. Mastering advanced rib design is the key to creating robust, efficient, and visually appealing components.

The best way to optimize plastic parts is through intelligent rib design. Properly designed ribs increase stiffness and strength without adding significant weight or material cost. By following key guidelines for thickness, height, spacing, and draft, you can prevent cosmetic defects like sink marks, improve mold flow during injection, and ensure the structural integrity of your final product.

Over my years in this industry, I’ve seen countless projects where the success or failure hinged on something as seemingly small as a rib. It’s a detail that’s easy to overlook but has a massive impact on the final product. I’ve worked with project managers like Alex, who know that getting these details right from the start saves a lot of headaches later. Let’s break down exactly how you can get them right every time.

What Are the Core Principles for Designing Ribs in Plastic Parts?

You know ribs are necessary for strength, but where do you begin? A poorly planned rib layout can introduce more problems than it solves, from cosmetic flaws to critical weak points. This uncertainty can lead to endless revisions, delaying your project and increasing costs. Following a few fundamental principles is the secret to ensuring your ribs add strength without creating new issues.

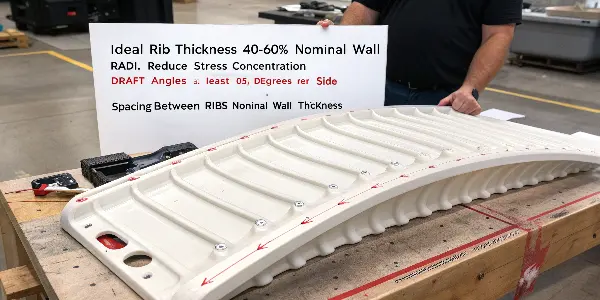

Effective rib design starts with proper thickness, ideally 40-60% of the nominal wall thickness to prevent sink marks. It also requires generous radii at the base to reduce stress concentration, and adequate draft angles of at least 0.5 degrees per side for easy ejection from the mold. Spacing ribs at least twice the nominal wall thickness apart is also crucial for uniform cooling and structural integrity.

The core principles of rib design are all about balancing structural needs with the realities of the injection molding process. It’s a game of managing plastic flow, heat, and pressure. When we ignore these rules, we fight against the physics of the process, leading to predictable failures. I remember working on a handheld device housing for a client; their initial design had ribs that were too thick and sharp at the base. During the first trial, we saw visible sink marks and found stress cracks forming under minor pressure. It was a classic case of overlooking the fundamentals. By simply adjusting the rib geometry according to these core principles, we solved both problems without a major redesign.

Key Dimensional Ratios for Ribs

To make this easier to follow, let’s break down the essential dimensional guidelines. Sticking to these ratios is your best defense against common molding defects and will give your part the strength it needs.

| Design Parameter | Recommended Guideline | Why It’s Important |

|---|---|---|

| Rib Thickness | 40% – 60% of nominal wall | Prevents sink marks and voids by managing shrinkage. Ensures uniform cooling. |

| Rib Height | ≤ 3 times the nominal wall | Provides significant stiffness. Taller ribs can cause filling issues and breakage. |

| Spacing | ≥ 2 times the nominal wall | Allows for proper cooling between ribs, preventing hot spots and warpage. |

| Base Radii | ≥ 0.5 times the nominal wall | Reduces stress concentration at the base, preventing cracks under load. Improves material flow. |

| Draft Angle | ≥ 0.5° per side | Facilitates easy and clean ejection of the part from the mold, preventing drag marks. |

The Right Way to Connect Ribs

How ribs connect to each other and to the main walls is just as important as their individual dimensions. Avoid converging multiple ribs into a single point. This creates a large mass of material that is extremely difficult to cool uniformly, leading to severe sink marks or voids. Instead, design ribs in a way that they meet other features with small, offset connections. This cellular or grid-like approach distributes stresses effectively and maintains uniform wall thickness, which is the ultimate goal in injection molding design. This approach ensures a much more stable and aesthetically pleasing final part.

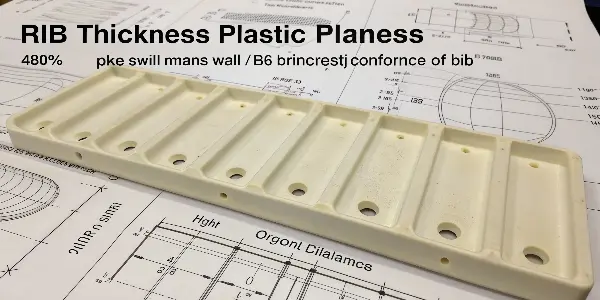

How Thick Should Ribs Be for Plastic Parts?

Choosing the right rib thickness often feels like a balancing act. Go too thick, and you’re guaranteed to see ugly sink marks on the outside of your part and waste expensive material. Go too thin, and the ribs won’t provide the necessary support, leading to a weak and flimsy product that fails in the field. There is a sweet spot, a rule of thumb that professional designers live by.

As a golden rule, a rib’s thickness should be between 40% and 60% of the main wall thickness of the part. This ratio is the single most important factor in preventing cosmetic defects like sink marks on the opposite surface. Going thicker creates cooling problems and visual flaws, while going thinner may not provide enough structural support. This range is the key to balancing strength with moldability.

The reason the 40-60% rule is so critical comes down to the cooling process. Plastic shrinks as it cools. A thick rib is a large mass of molten plastic that will cool much slower than the thinner wall it’s attached to. As this thick section of plastic cools and shrinks, it pulls the still-soft surface of the main wall inward, creating a depression we call a sink mark. It’s a purely physical phenomenon. By keeping the rib thinner than the wall, you ensure that both sections can cool and shrink at a more uniform rate, minimizing this pulling effect and keeping your part surface smooth and clean.

Material-Specific Considerations

While the 40-60% rule is an excellent starting point, the specific material you use can shift the ideal ratio. Different plastics shrink at different rates and have different levels of viscosity. For example, materials that are more prone to sinking require you to be more conservative with rib thickness.

| Material Type | Examples | Recommended Rib Thickness | Notes |

|---|---|---|---|

| Amorphous | PC, ABS, PS | 40% – 50% of wall | These materials have a wide softening range and are very prone to sink marks. It’s best to stay on the lower end of the thickness range. |

| Semi-Crystalline | PP, PE, Nylon (PA) | 50% – 60% of wall | These materials have a sharper melting point and tend to be less prone to sinking, so you have a bit more flexibility. |

| Filled Resins | Glass-Filled Nylon, PC/ABS | 50% – 70% of wall | The fibers (like glass or carbon) in the resin reduce and control the overall shrinkage, allowing for slightly thicker ribs without causing sink. |

What Happens When You Break the Rule?

Going beyond 60% thickness is a common mistake I see from less experienced designers. They assume "thicker rib, stronger part." While that might be true from a pure structural standpoint, it ignores the manufacturability. The result is almost always a prominent sink mark on the cosmetic side of the part—what we call the ‘A’ surface. For a project manager like Alex working on consumer electronics, a visual flaw like that is an immediate rejection. It makes the product feel cheap and poorly made. In contrast, making a rib too thin (less than 40%) simply means it won’t do its job. It will fail to provide the stiffness required, and the part may warp or break under normal use.

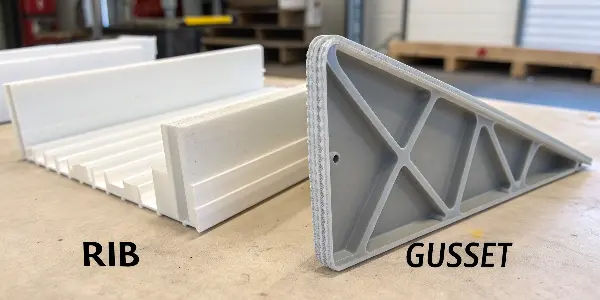

What’s the Difference Between a Rib and a Gusset?

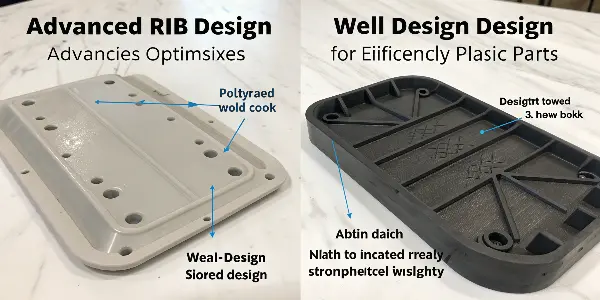

It’s easy to get ribs and gussets confused, as they both serve to strengthen a plastic part. However, they are used in different situations and solve different structural problems. Using the wrong one can lead to an over-engineered, costly part or, worse, a part that fails unexpectedly. Understanding their distinct roles is key to efficient and effective part design.

The main difference is their primary function and location. A rib is a thin, wall-like feature added to a flat surface to increase its stiffness and prevent bending across the plane. A gusset is a triangular support element used to reinforce features that stick out perpendicularly, like a boss or a wall, preventing them from breaking off under stress.

Think of it this way: a rib is like the joist under a floorboard, preventing the entire floor from sagging. A gusset is like the bracket supporting a shelf on a wall, preventing the shelf from snapping off at the connection point. They are both reinforcements, but they fight different forces in different areas. I’ve seen this firsthand on many projects. For instance, we worked on an enclosure where a mounting post needed to withstand significant side-to-side force. The initial design used ribs along the base of the enclosure, but the post itself was still the weak point. By adding small, triangular gussets connecting the post to the floor of the enclosure, we reinforced that specific connection point without adding unnecessary material elsewhere.

When to Use a Rib

You should use ribs when your goal is to add rigidity to a large, flat area. Without ribs, a thin plastic wall can feel flimsy and may warp easily.

- Primary Function: To increase the bending stiffness of a plane.

- Common Applications:

- Large, flat surfaces on electronic housings.

- Battery compartment covers.

- Automotive interior panels.

- Lids and bases of containers.

- Design Consideration: Ribs are most effective when they run parallel to the direction of bending stress. A grid or cross-hatched pattern of ribs (a "waffle" pattern) is excellent for providing multi-directional stiffness.

When to Use a Gusset

Gussets are your go-to solution for reinforcing features that project from a surface and are subject to bending or shear forces at their base.

- Primary Function: To strengthen the connection between two perpendicular surfaces.

- Common Applications:

- Supporting screw bosses to prevent them from breaking off during assembly.

- Reinforcing snap-fit features.

- Strengthening the junction between a side wall and the base of a box.

- Design Consideration: Gussets are essentially small, triangular ribs. They should follow the same thickness and draft rules as regular ribs to avoid sink marks and molding issues. Spacing multiple gussets around the base of a boss is a very common and effective technique.

What Are Key Design Guidelines for Injection Molding?

You want your plastic part to be strong, look great, and be easy to manufacture. But the success of your design depends on more than just ribs. If your overall design ignores the fundamental rules of injection molding, even the best-planned ribs won’t save it. This oversight can lead to a cascade of problems, from parts that won’t fill correctly to ones that get stuck in the mold, causing costly delays and rework.

Beyond ribs, the most critical design guidelines for injection molding are maintaining a uniform wall thickness, adding draft angles to all vertical surfaces for easy part ejection, and incorporating generous radii on all inside and outside corners to reduce stress and improve plastic flow. These three principles are the foundation of any successful and manufacturable plastic part.

These rules aren’t arbitrary; they are dictated by the physics of how molten plastic behaves under immense pressure and how it cools inside a steel mold. I’ve seen countless designs from talented product designers that looked great on a screen but were impossible to mold. The most common issue is a lack of uniform wall thickness. A part with thick and thin sections right next to each other will cool at different rates, causing the part to warp and twist like a potato chip. As a mold maker, my job is to spot these issues before we even cut steel. Working with clients like Alex, we often spend a lot of time in the DFM (Design for Manufacturability) phase, tweaking the design to respect these core principles. It’s time that is incredibly well spent.

The Three Pillars of Moldable Design

Let’s look at these three core pillars in more detail. Getting these right will solve 90% of common molding problems.

-

Uniform Wall Thickness: This is the number one rule. The goal is to design a part where the plastic has to flow a similar distance and cool at a similar rate everywhere.

- Why? Prevents internal stresses, warpage, and sink marks. Ensures the part fills completely and predictably.

- How? If you need to change thickness, make the transition gradual and smooth, not abrupt. If you need a thick section for strength, consider using ribs or cores to hollow it out and maintain a consistent wall.

-

Draft Angles: Every surface parallel to the direction the mold opens and closes needs to be slightly angled.

- Why? As plastic cools, it shrinks and grips onto the mold core. Without a draft angle, the friction during ejection can cause drag marks, scratches, or even break the part.

- How? A general rule is to apply at least 1-2 degrees of draft for most textures. For smooth polished surfaces, a minimum of 0.5 degrees is often acceptable. The deeper the feature, the more draft you will need.

-

Corner Radii (Fillets): Sharp corners are a big problem in plastic parts.

- Why? Sharp internal corners create huge stress concentrations, making the part prone to cracking. They also make it difficult for the molten plastic to flow smoothly, which can lead to incomplete filling. Sharp external corners on the part correspond to sharp internal corners in the mold, which are difficult to machine and can be weak points in the tool itself.

- How? A good rule is to make the inside radius at least 0.5 times the wall thickness and the outside radius 1.5 times the wall thickness (inside radius + wall thickness).

By building your design on these three foundational principles, you create a part that is not only strong and functional but also efficient and reliable to manufacture, which is the ultimate goal.

Conclusion

Mastering rib design and following core injection molding principles are not just about avoiding defects. It’s about creating stronger, lighter, and more cost-effective parts. By focusing on rib thickness, spacing, draft, and combining them with uniform walls and rounded corners, you ensure your design is optimized for manufacturing.